Method for reducing carbide liquation level in high-carbon chromium bearing steel

A high-chromium bearing and carbide technology, applied in the field of steel processing, can solve problems such as prolonging heating time and economic loss, and achieve the effects of improving cost performance, protecting the environment and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

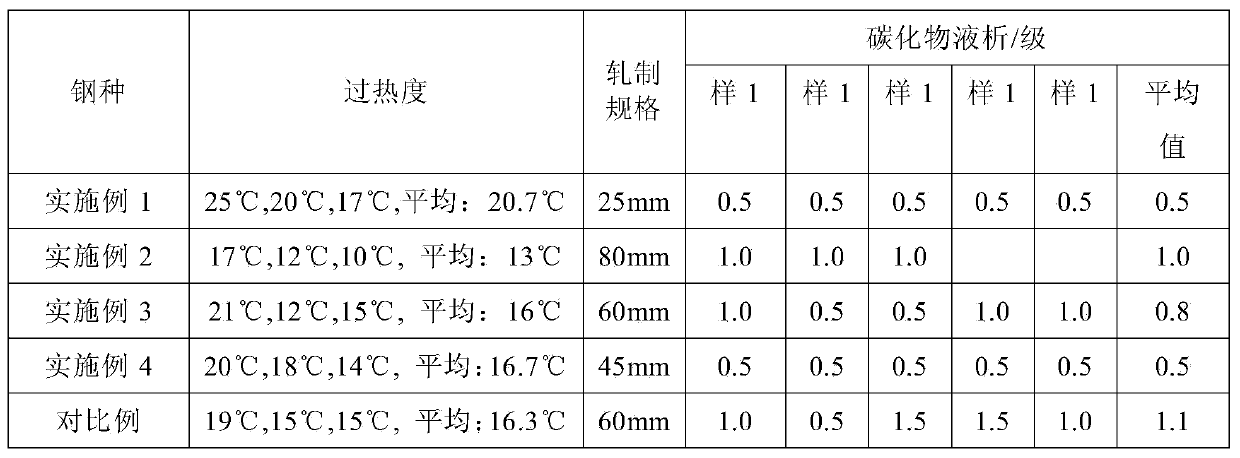

Examples

Embodiment 1

[0028] The main components of GCr15 bearing steel A are: [C]: 1.01%, [Si]: 0.24%, [Mn]: 0.36%, [Cr]: 1.52%, [P]: 0.013%, [S]: 0.002%, [Mo]: 0.04%, [Cu]: 0.15%, [Ni]: 0.04%, and the rest are iron and impurities.

[0029] The section size of electric furnace smelting and continuous casting slab is: 150×150mm, the temperature of continuous casting tundish is respectively: 1475°C, 1470°C, 1467°C (the liquidus temperature of GCr15 steel is: 1450°C, and the degree of superheat is: 25°C, 20°C, 17°C);

[0030] The continuous casting slab is heated in a built-in regenerative walking heating furnace with a length of 34m×width of 9.8m. The temperature of the heating section is controlled within the range of 1150-1175°C, and the temperature of the soaking section is within the range of 1155-1175°C;

[0031] The whole heating time is controlled as 130min;

[0032] The combustion reversing period of the heating furnace is 100s, of which the combustion time and the cease-fire time are 50s ...

Embodiment 2

[0036] The main components of GCr15 bearing steel B are: [C]: 0.99%, [Si]: 0.29%, [Mn]: 0.33%, [Cr]: 1.49%, [P]: 0.011%, [S]: 0.001%, [Mo]: 0.04%, [Cu]: 0.12%, [Ni]: 0.03%, and the rest are iron and impurities.

[0037] Converter smelting and continuous casting slab section size: 240×240mm, continuous casting tundish temperature: 1467°C, 1462°C, 1460°C (superheat: 17°C, 12°C, 10°C);

[0038] The continuous casting slab is heated in a built-in regenerative walking heating furnace with a length of 24m×width of 9.8m. The temperature of the heating section is controlled in the range of 1185-1220°C, and the temperature of the soaking section is in the range of 1180-1220°C;

[0039] The whole heating time is controlled to 240min;

[0040] The combustion reversing period of the heating furnace is 180s, of which the combustion time and the cease-fire time are 90s respectively, and the initial combustion flame injection angle is set at 9°, and every 15s, use the adjustment plate in th...

Embodiment 3

[0044] The main components of GCr15 bearing steel C are: [C]: 1.00%, [Si]: 0.25%, [Mn]: 0.30%, [Cr]: 1.45%, [P]: 0.012%, [S]: 0.002%, [Mo]: 0.04%, [Cu]: 0.13%, [Ni]: 0.02%, and the rest is iron and impurities.

[0045] Converter smelting and continuous casting slab section size: 200×200mm, continuous casting tundish temperature: 1471°C, 1462°C, 1465°C (superheat: 21°C, 12°C, 15°C);

[0046] The continuous casting slab is heated in a built-in regenerative walking heating furnace with a length of 24m×width of 9.8m. The temperature of the heating section is controlled in the range of 1170-1210°C, and the temperature of the soaking section is in the range of 1175-1210°C;

[0047] The whole heating time is controlled as 180min;

[0048] The combustion reversing period of the heating furnace is 150s, of which the combustion time and the cease-fire time are 75s respectively, and the initial combustion flame injection angle is set to 11°. Every 15s, use the adjustment plate in the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com