Aluminium-silicon-copper-magnesium series deforming alloy and its preparing method

A technology of deforming aluminum alloy and aluminum silicon copper, which is applied in the field of metal materials, can solve problems such as high temperature performance, poor cutting performance and corrosion resistance, failure to meet high performance index requirements, alloy use restrictions, etc., to reduce harmful effects and improve Room temperature and high temperature performance, effect of alloy cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

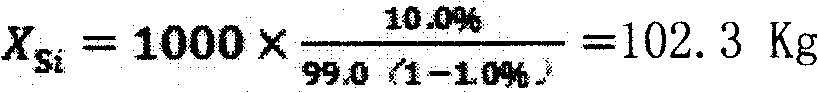

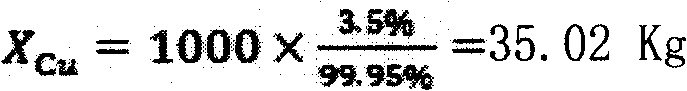

[0027] Prepare 1000Kg of aluminum-silicon-copper-magnesium deformed aluminum alloy containing silicon: 10.0%; copper: 3.5%; magnesium: 0.5%; the balance is aluminum (the composition ratios are all weight percentages, the same below), and the preparation method is as follows:

[0028] (1). According to the weight percentage of the aluminum-silicon-copper-magnesium series deformed aluminum alloy components, weigh the raw materials aluminum, silicon, copper and magnesium with a purity greater than 99.7%, and set them aside;

[0029] For the preparation of the above raw materials, refer to Volume 3 of "Casting Handbook", Casting Non-ferrous Alloys, 2nd Edition, Machinery Industry Press, 2001.10, P187-188, and experience to determine the burning loss of alloying elements, aluminum: 1.5%, silicon: 1% , Magnesium: 20%.

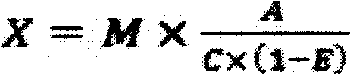

[0030] Addition calculation formula: X = M × A C × ...

Embodiment 2

[0059] Prepare 1000 Kg of aluminum-silicon-copper-magnesium-based deformed aluminum alloy containing silicon: 11.0%, copper: 3.0%, magnesium: 0.4%, and the balance is aluminum.

[0060] Take the same process steps as in Example 1, wherein the calculated amounts of each raw material added in step (1) are: aluminum ingot 871.65Kg, silicon block 112.23Kg, pure copper 30.02Kg, magnesium block 5.00Kg.

[0061] After testing, the composition of the obtained alloy is: silicon: 11.0%; copper: 3.0%; magnesium: 0.4%; the balance is aluminum. The tensile strength of the alloy in the as-cast state is 258MPa, the elongation after fracture is 8.6%, and the hardness is 112HB; after heat treatment, the tensile strength can reach 394MPa, the elongation after fracture can reach 6.3%, and the hardness is 136-141HB.

Embodiment 3

[0063] Prepare 1000Kg of aluminum-silicon-copper-magnesium deformed aluminum alloy containing silicon: 12.0%, copper: 4.0%, magnesium: 0.6%, and the balance is aluminum.

[0064] Take the same process steps as in Example 1, wherein the amount of each raw material added in step (1) is: aluminum ingot 849.25Kg, silicon block 122.44Kg, pure copper 40.02Kg, magnesium block 6.11Kg.

[0065] After testing, the obtained alloy composition is: silicon: 12.0%; copper: 4.0%; magnesium: 0.6%; the balance is aluminum. The tensile strength of the alloy in the as-cast state is 263MPa, and the elongation after fracture is 8.4%. The hardness is 115HB; the tensile strength after heat treatment can reach 400MPa, the elongation after breaking can reach 4.9%, and the hardness is 136-141HB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com