Method for producing low-carbon olefins by using petroleum hydrocarbon

A technology of low-carbon olefins and petroleum hydrocarbons, which is applied in the petroleum industry, hydrocarbon cracking to produce hydrocarbons, and catalytic cracking. It can solve the problems of energy demand and low heat transfer efficiency, and achieve the goals of improving heat transfer effects, protecting the environment, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

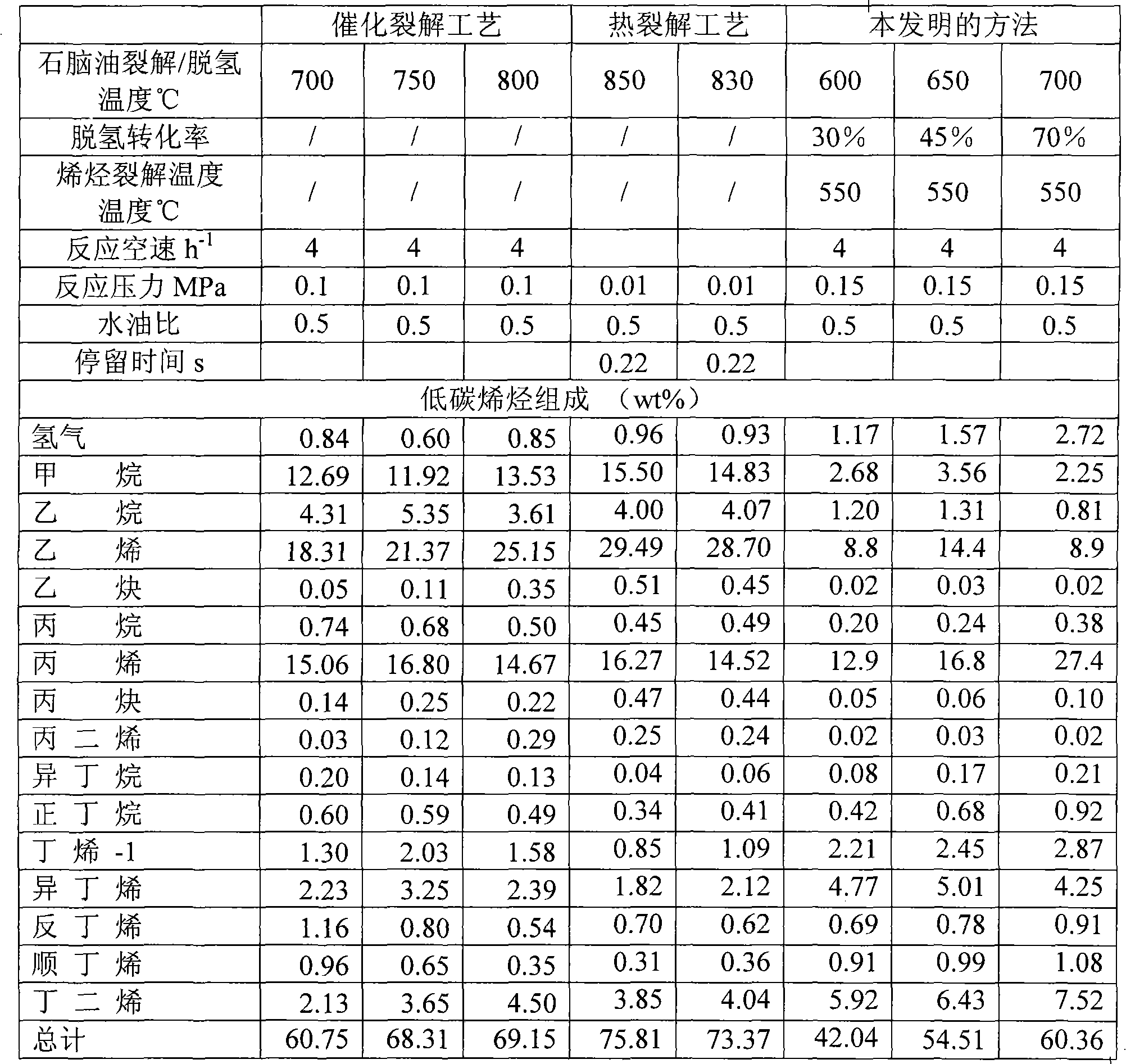

Embodiment 1

[0052] The above-mentioned light naphtha (C 5 ~C 10 ) After being preheated to about 100℃ by a heat exchanger, it is mixed with water, hydrogen and oxygen and then enters the hydrogen combustion direct heating zone. The hydrogen combustion heating zone consists of a low-temperature hydrogen combustion reactor and two high-temperature hydrogen combustion reactors. The reaction conditions in the combustion heating zone are: weight hourly space velocity 4h -1 , The reaction pressure is 0.15MPa, and the weight ratio of water vapor to oil is 0.5. Low temperature hydrogen combustion reactor is equipped with hydrogen combustion Pt / Al 2 O 3 Catalyst (produced by Beijing Research Institute of Chemical Industry, brand BHO-L), the temperature of the stream leaving the low-temperature hydrogen combustion reactor is 150°C, and then enters the Pt / Al containing hydrogen combustion catalyst 2 O 3 The high-temperature hydrogen combustion reactor (produced by Beijing Research Institute of Chemical...

Embodiment 2

[0054] Except that the temperature of the stream leaving the hydrogen combustion reactor was changed to 650°C, low-carbon olefins were produced using the same method and conditions as in Example 1.

Embodiment 3

[0056] Except that the temperature of the stream leaving the hydrogen combustion reactor was changed to 600°C, low-carbon olefins were produced using the same method and conditions as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com