Hydrogen-oxygen fuel-rich precombustion chamber for full flow staged combustion cycle engine

A pre-combustion chamber, hydrogen technology, applied in machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of non-replacement, pre-combustion chamber burning, unfavorable research work, etc., to achieve weight reduction and material saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

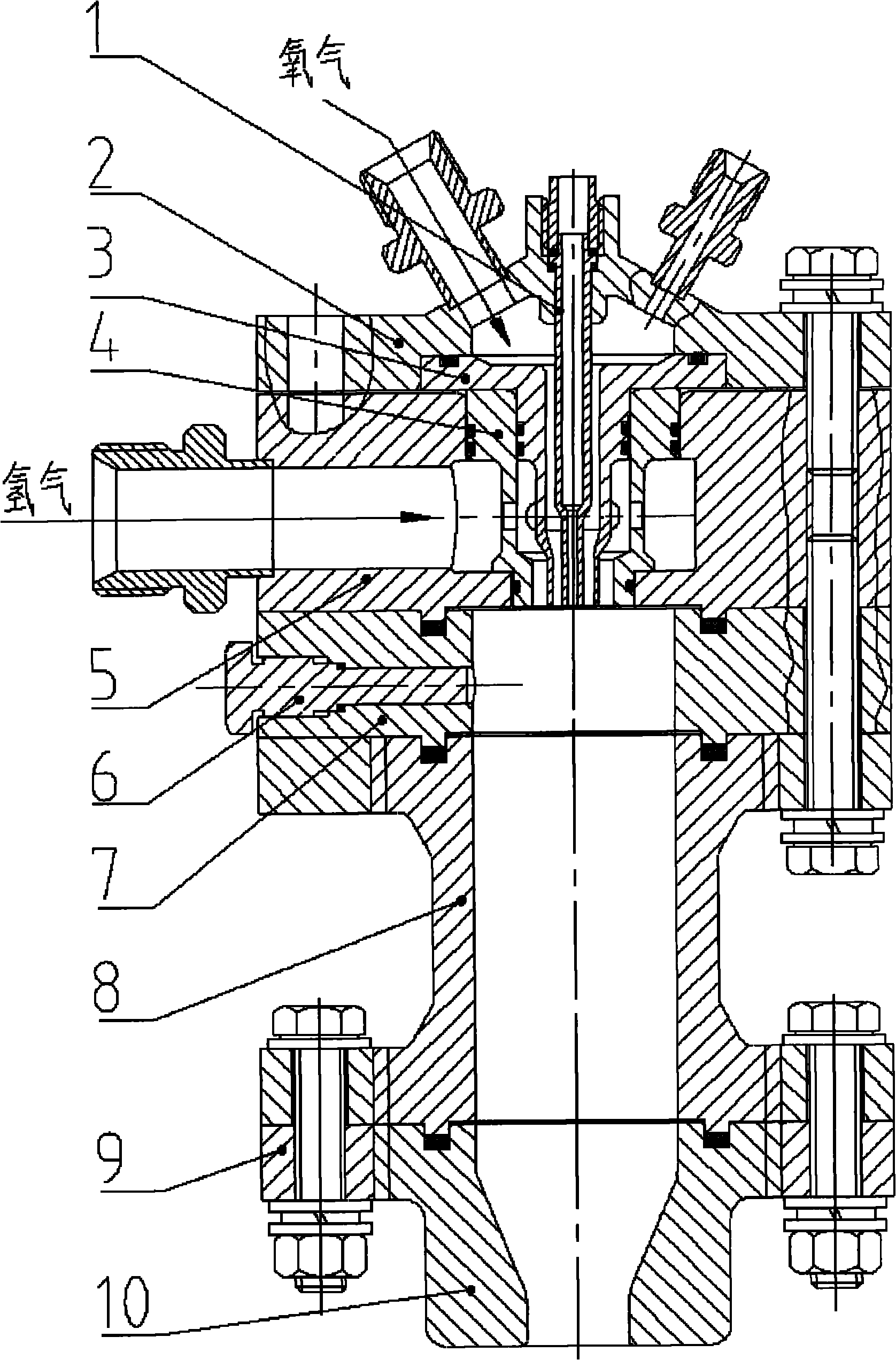

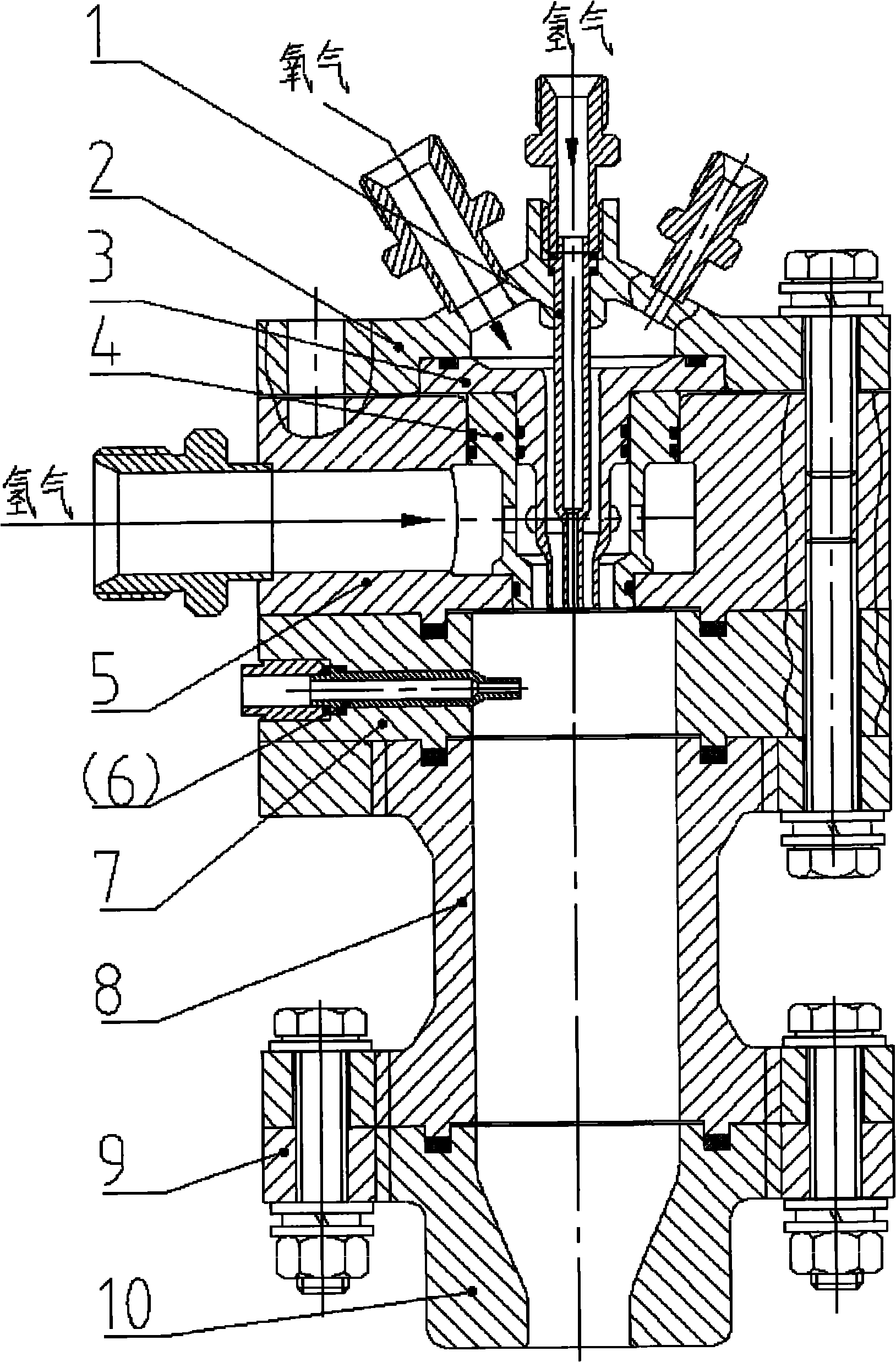

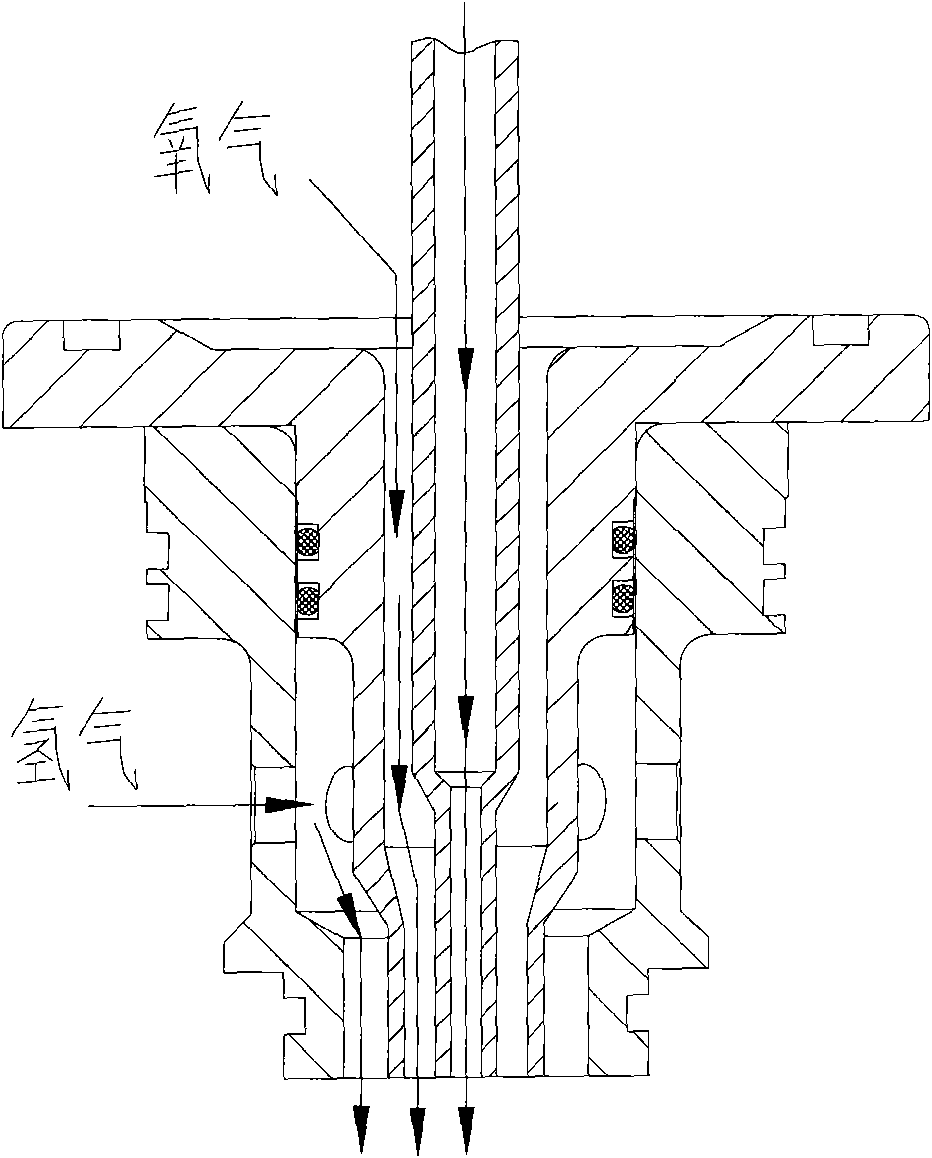

[0013] The gas-hydrogen-oxygen-rich pre-combustion chamber adopts a hydrogen-oxygen dynamic resonant igniter. The igniter is divided into a hydrogen circuit and an oxygen circuit, which are connected to the hydrogen and oxygen respectively.

[0014] When head ignition is used, the plug 6 is installed on the connecting section 7 to play a sealing role. After the igniter is ignited successfully, the oxygen supply of the oxygen ignition circuit of the igniter is closed, and the hydrogen ignition circuit continues to pass hydrogen, and the igniter is converted into a hydrogen injection. injector. At this time, the hydrogen injection from the ignition tube 1, the oxygen injection from the oxygen nozzle part 3 and the hydrogen injection from the hydrogen nozzle part 4 jointly constitute a hydrogen-oxygen-hydrogen combustion mode.

[0015] When adopting the front-end ignitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com