The automatic adjustment control method of hot water constant pressure control system setting

A constant pressure control and automatic adjustment technology, which is applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as the inability to realize the user's sleep shutdown state, affecting the user, and difficulty in reaching the rated pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The hot water constant pressure control system sets the automatic adjustment control method, including the following steps:

[0047] (1) Status judgment: When the water pump is used in the hot water system to supply water to the system through pressurization, the system speed reaches the maximum rated speed, and the pressure can never reach the normal set pressure of the system. It can be judged that there is a large cavitation in the system. Make settings adjustments. Therefore, according to whether the user has water, it is divided into water pump with flow output and no flow output for analysis and judgment;

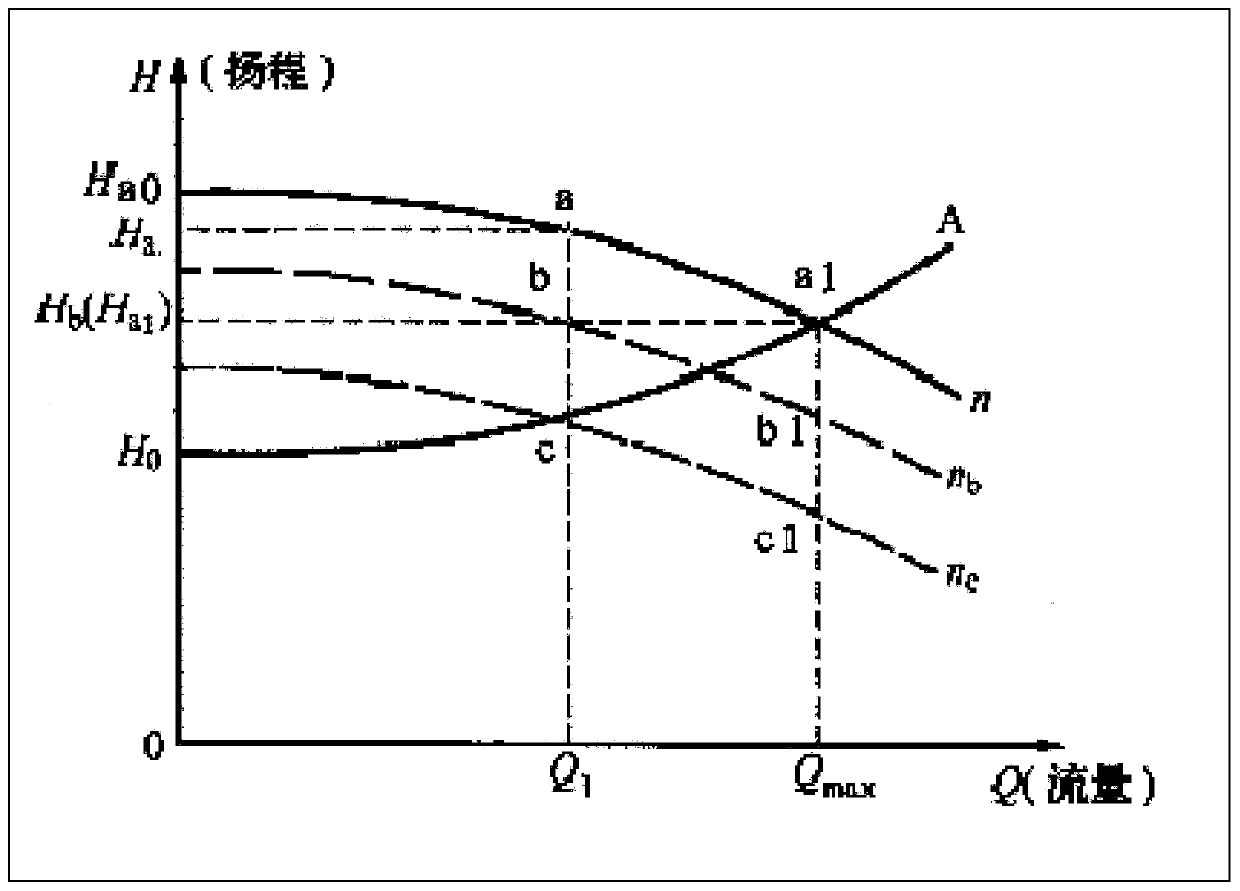

[0048] No flow output: when the system pressure cannot reach the set value and the speed is at the maximum, please refer to the attached figure 1 , the speed n is the maximum speed of the system. At this time, the system flow is 0, and the system pressure is Ha0. Judging by the sampled pressure, when the pressure does not change all the time, it can be determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com