Regular honeycomb ceramic carbon carrier based doped ozone catalyst for advanced treatment of industrial wastewater and preparation method of regular honeycomb ceramic carbon carrier based doped ozone catalyst

A technology of honeycomb ceramics and advanced treatment, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the defects of mechanical strength, mass transfer efficiency and Poor ozone utilization efficiency, easy damage and loss, etc., to achieve the effect of ensuring catalytic performance and reusability, regular flow field, and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

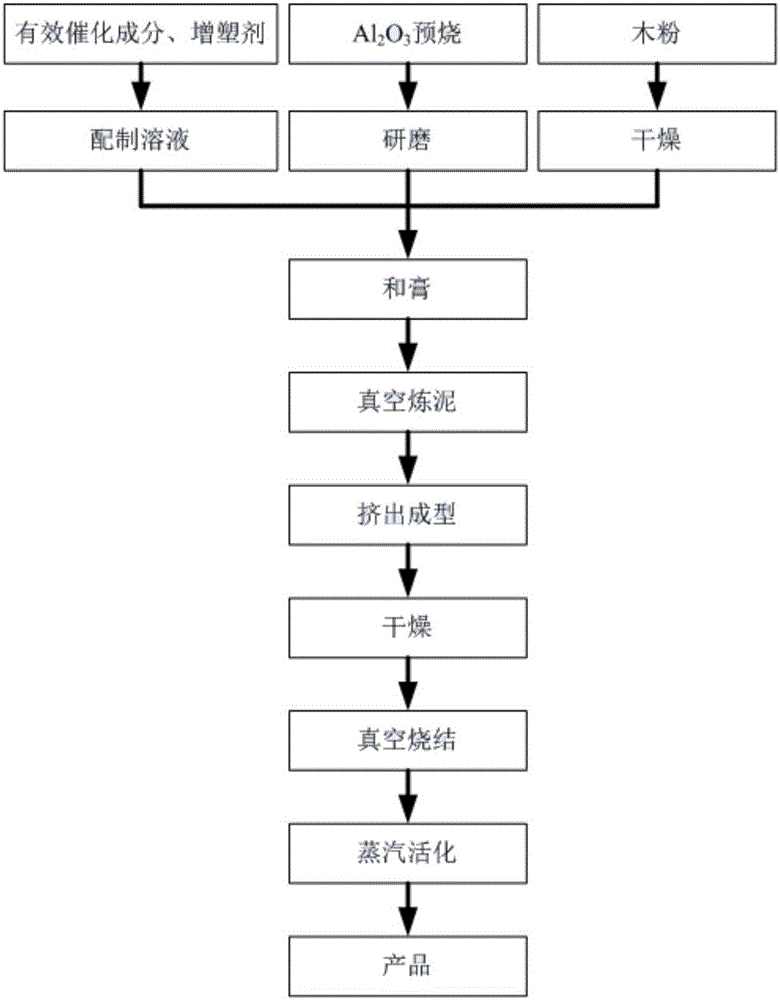

[0037] The above-mentioned doped type ozone catalyst of the present invention is based on the Al 2 o 3 The powder is mixed with wood flour in a specific ratio, with hydroxypropyl methylcellulose, polyethylene glycol, dysprosium nitrate, and molybdenum nitrate aqueous solution as forming aids, after kneading paste, mud refining, extrusion molding, drying, vacuum sintering, steaming It is prepared by activation and other processes, and its flow chart is as follows figure 1 Shown, the concrete steps of the preparation method of this doping type ozone catalyst are:

[0038] (1)Al 2 o 3 Pre-burning of powder: Al 2 o 3 The powder is baked at 1400°C for 4 to 8 hours to transform it into α-Al 2 o 3 , so that the volume shrinkage and expansion during the sintering process can be effectively controlled, the cracking during the sintering process can be reduced, and the sintering yield can be improved;

[0039] (2) Powder grinding: the pre-fired Al 2 o 3 The powder is ground to ...

Embodiment 1

[0048] Will Al 2 o 3 The powder is calcined at 1400°C for 8 hours to convert all of it into α-Al 2 o 3 , so as to control the volume shrinkage and expansion during the sintering process, reduce the cracking during the sintering process, and improve the sintering yield; the pre-fired Al 2 o 3 The powder is ground into a uniform powder with an average particle size of about 150 mesh for future use. Dry wood powder with an average particle size of about 150 mesh in an oven at 60°C for 6 hours for later use; mix hydroxypropyl methylcellulose, polyethylene glycol, dysprosium nitrate, molybdenum nitrate and water to prepare a molding aid solution, wherein The mass concentration of hydroxypropyl methylcellulose is 3.5%, the mass concentration of polyethylene glycol is 6%, and the mass concentration of dysprosium nitrate and molybdenum nitrate is 50%; the dried wood powder and Al 2 o 3 The powder is mixed according to the mass ratio of 1:30 to obtain a mixed powder, and a 4% mas...

Embodiment 2

[0051] Will Al 2 o 3The powder is calcined at 1400°C for 8 hours to convert all of it into α-Al 2 o 3 , so as to control the volume shrinkage and expansion during the sintering process, reduce the cracking during the sintering process, and improve the sintering yield; the pre-fired Al 2 o 3 The powder is ground into a uniform powder with an average particle size of about 500 mesh for later use. Dry wood powder with an average particle size of about 500 mesh in an oven at 60°C for 6 hours for later use; mix hydroxypropyl methylcellulose, polyethylene glycol, dysprosium nitrate, molybdenum nitrate and water to prepare a molding aid solution, wherein The concentration of hydroxypropyl methylcellulose is 3.5%, the concentration of polyethylene glycol is 6%, and the concentrations of dysprosium nitrate and molybdenum nitrate are 50% respectively; the dried wood powder and Al 2 o 3 The powder is mixed according to the mass ratio of 1:30, and 4% of the mass proportion of formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com