Method of regenerating activity of calcium based absorbent and cyclically removing CO2

A calcium-based absorbent and removal technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of absorbent inactivation, capture performance decline, etc., to maintain activity, inhibit absorbent activity decline, The effect of reducing the discharge of inactivated absorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

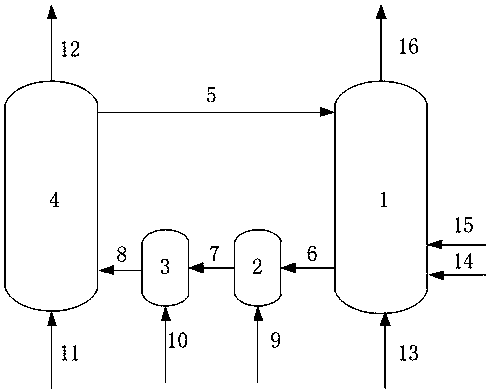

[0019] Such as figure 1 As shown, supplemented with fresh calcium-based absorbent15, carbon-based fuel14, O 2 13 into the calcining decomposition reactor 1, carbon-based fuel 14 and O 2 The combustion reaction of 13 provides heat for the decomposition of the absorbent, and by regulating the carbon-based fuel 14 and O 2 13 ratio and then control the temperature of calcining decomposition reactor 1 at 800-1000°C; fresh supplementary absorbent 15 is heated and decomposed into CaO and releases CO 2 , the produced CaO 6 is sent to the steam activation reactor, CO 2 After the enriched flue gas 16 is discharged from the top of the calcining decomposition reactor 1, it can be directly sealed or used for other purposes, so as to realize the reduction of CO in the flue gas. 2 removal and trapping; the temperature of steam activation reactor 2 is 300-400°C, and the reaction atmosphere is steam / N 2 Or steam / air mixed gas 9, wherein the steam concentration is 10-100%; CaO 6 from the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com