Preparation and application for modified pollen biomass carbon composite acrylate oil-absorbing material

A technology of acrylates and biomass carbon, which is applied in the preparation/purification of carbon, other chemical processes, chemical instruments and methods, etc., can solve the problems of high cost, secondary pollution of the environment, complicated preparation process, etc., and achieve the effect of oil absorption The effect of lifting, accelerating oil storage space and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

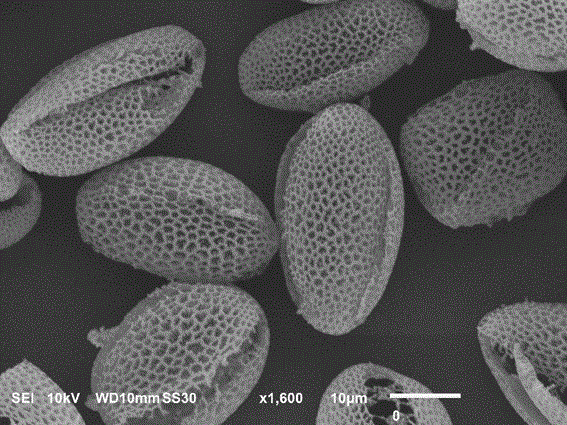

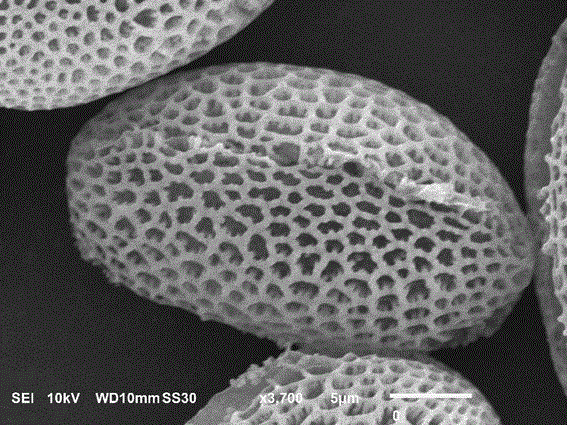

[0033] a) Pollen pretreatment step: Soak 5 g of rapeseed pollen grains in 75 mL ethanol solution for 5 h, then ultrasonically clean for 2 h, filter with suction, wash with water and ethanol for 3 times, collect 5 g of pollen and disperse them in a solution containing 12.5 mL formaldehyde and 37.5 mL ethanol mixture for 10 min, suction filtered, washed with water and ethanol three times, then soaked in 60 mL of 12 mol / L sulfuric acid for dehydration under magnetic stirring for 4 h, suction filtered, and removed Wash with deionized water until the filtrate is neutral, and dry at 80°C.

[0034] b) Modification step of pollen particles: the pollen obtained in step a) was heated to 500°C in nitrogen and calcined for 2 h to obtain a carbonized pollen skeleton. at 100°C with HNO 3 The pollen surface was activated by steam for 5 h, cooled, filtered with suction, washed with water and ethanol until the filtrate was neutral, and dried at 80°C for 12 h. The resulting 0.3 g of nitric acid...

Embodiment 2

[0037] a) Pollen pretreatment step: Soak 5 g of rapeseed pollen grains in 75 mL ethanol solution for 5 h, then ultrasonically clean for 2 h, filter with suction, wash with water and ethanol for 3 times, collect 5 g of pollen and disperse in 18 mL of formaldehyde and 32 mL of ethanol mixture for 10 min, suction filtered, washed with water and ethanol three times, then soaked in 60 mL of 12 mol / L sulfuric acid for dehydration under magnetic stirring for 4 h, suction filtered, and removed Wash with deionized water until the filtrate is neutral, and dry at 80°C.

[0038] b) Modification step of pollen particles: the pollen obtained in step a) was heated to 500°C in nitrogen and calcined for 2 h to obtain a carbonized pollen skeleton. at 110 °C with HNO 3 The pollen surface was activated by steam for 5 h, cooled, filtered with suction, washed with water and ethanol until the filtrate was neutral, and dried at 80°C for 12 h. Disperse the obtained 0.3 g of nitric acid-activated pol...

Embodiment 3

[0041] a) Pollen pretreatment step: Soak 5 g of rapeseed pollen grains in 75 mL ethanol solution for 5 h, then ultrasonically clean for 2 h, filter with suction, wash with water and ethanol for 3 times, collect 5 g of pollen and disperse in 20 mL formaldehyde and 30 mL ethanol mixture for 10 min, suction filtered, washed with water and ethanol for 3 times, then soaked in 60 mL of 12 mol / L sulfuric acid for dehydration under magnetic stirring for 4 h, suction filtered, and removed Wash with deionized water until the filtrate is neutral, and dry at 80°C.

[0042] b) Modification step of pollen grains: the pollen obtained in step a) was heated to 700°C in nitrogen and calcined for 2 h to obtain carbonized pollen skeleton. at 130°C with HNO 3 The pollen surface was activated by steam for 5 h, cooled, filtered with suction, washed with water and ethanol until the filtrate was neutral, and dried at 80°C for 12 h. The resulting 0.3 g of nitric acid-activated pollen was dispersed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com