System and method for producing activated carbon and hydrogen through low-temperature pyrolysis of biomass steam

A technology for the production of activated carbon and low-temperature pyrolysis, which is applied to chemical instruments and methods, carbon compounds, and the manufacture of combustible gases, etc., to achieve the effects of simplifying the production process, improving heat utilization, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

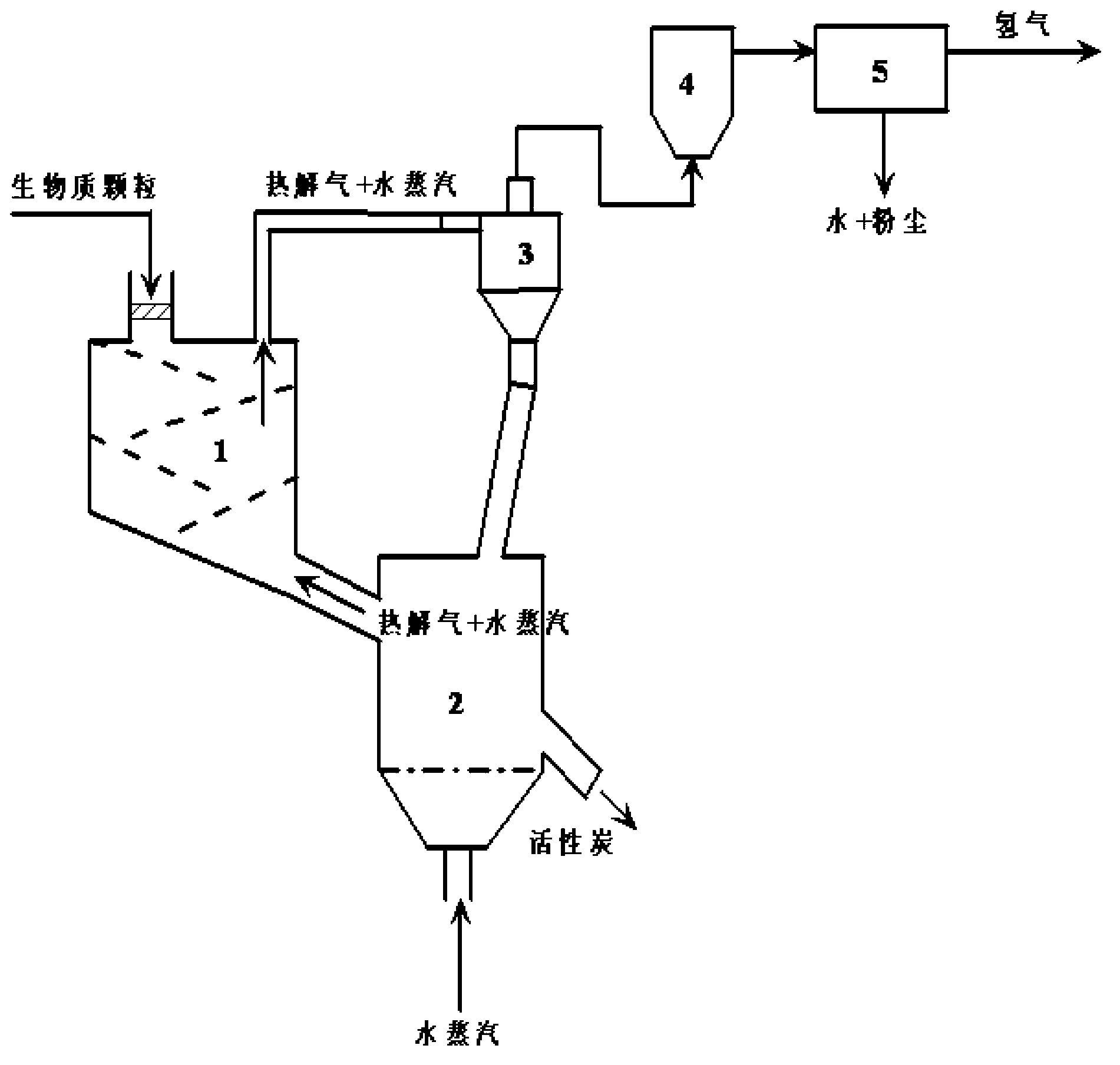

[0033] refer to figure 1 , this embodiment takes bark, stem crops and sawn wood as raw materials to prepare activated carbon and hydrogen by low-temperature steam pyrolysis of biomass as an example. The processing capacity of raw materials is 0.5t / h, and the particle size is 5.0-10.0mm. The as-received basis moisture content was 15.0%. The specific embodiment comprises the processing steps of following order:

[0034] (1) Send the biomass raw material with a particle size of 5.0 to 10.0 mm into the biomass pretreatment drying unit 1; the material moves downward along the guiding porous partition of the biomass pretreatment drying chamber, and is pyrolyzed through the guiding partition. The mixture of gas and water vapor is contacted in countercurrent, heat exchanged and dried. The opening ratio of the guide partition is 20.0%, and the aperture is 1.5mm;

[0035] (2) The dried material enters the steam low-temperature pyrolysis unit 2, and is evenly distributed on the porous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com