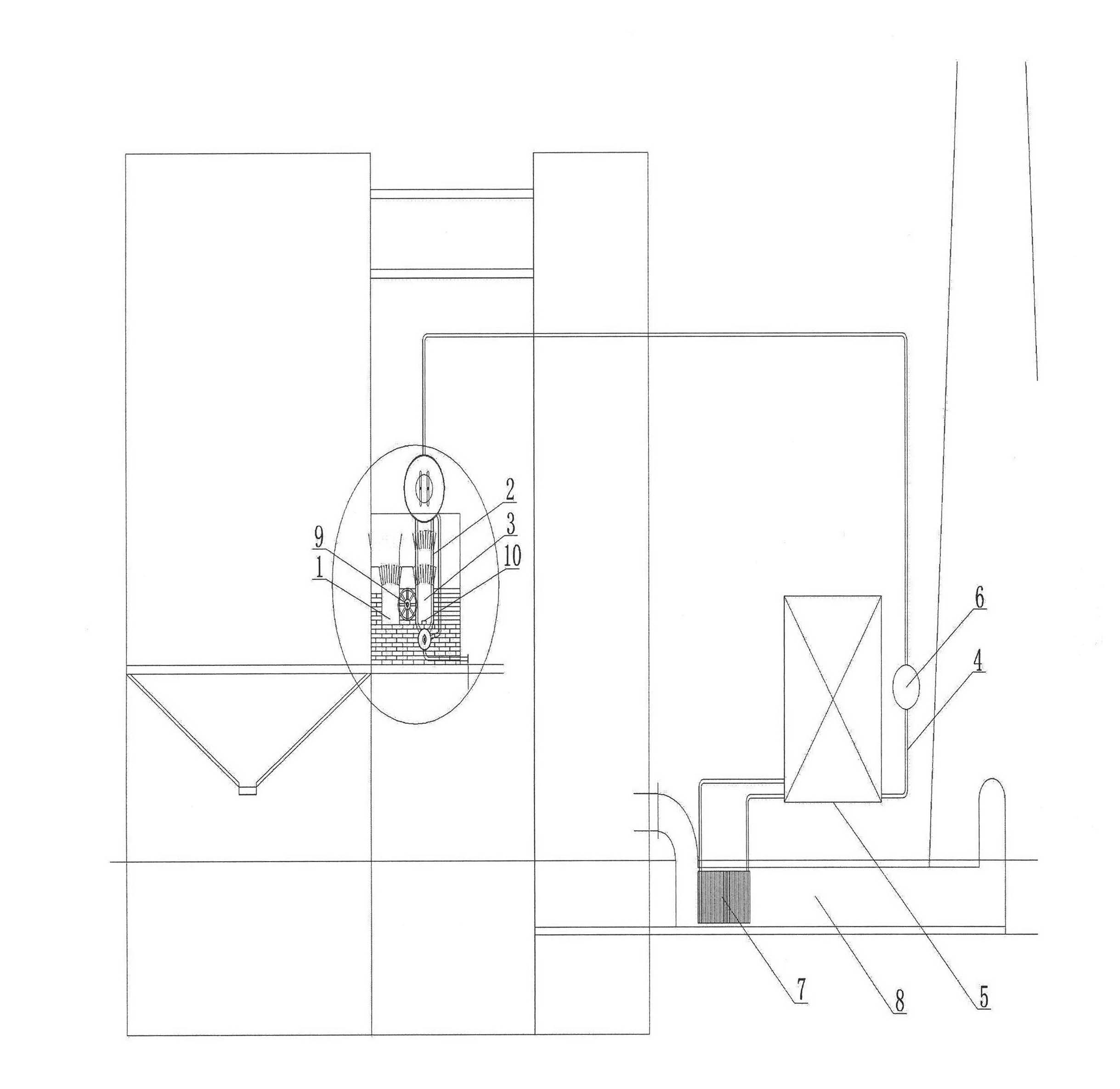

Saddle type activation furnace steam self-supply device

An activation furnace and steam technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of polluting the environment, large pollution emissions, difficult synchronization and coordination of steam consumption, etc., to reduce production costs and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

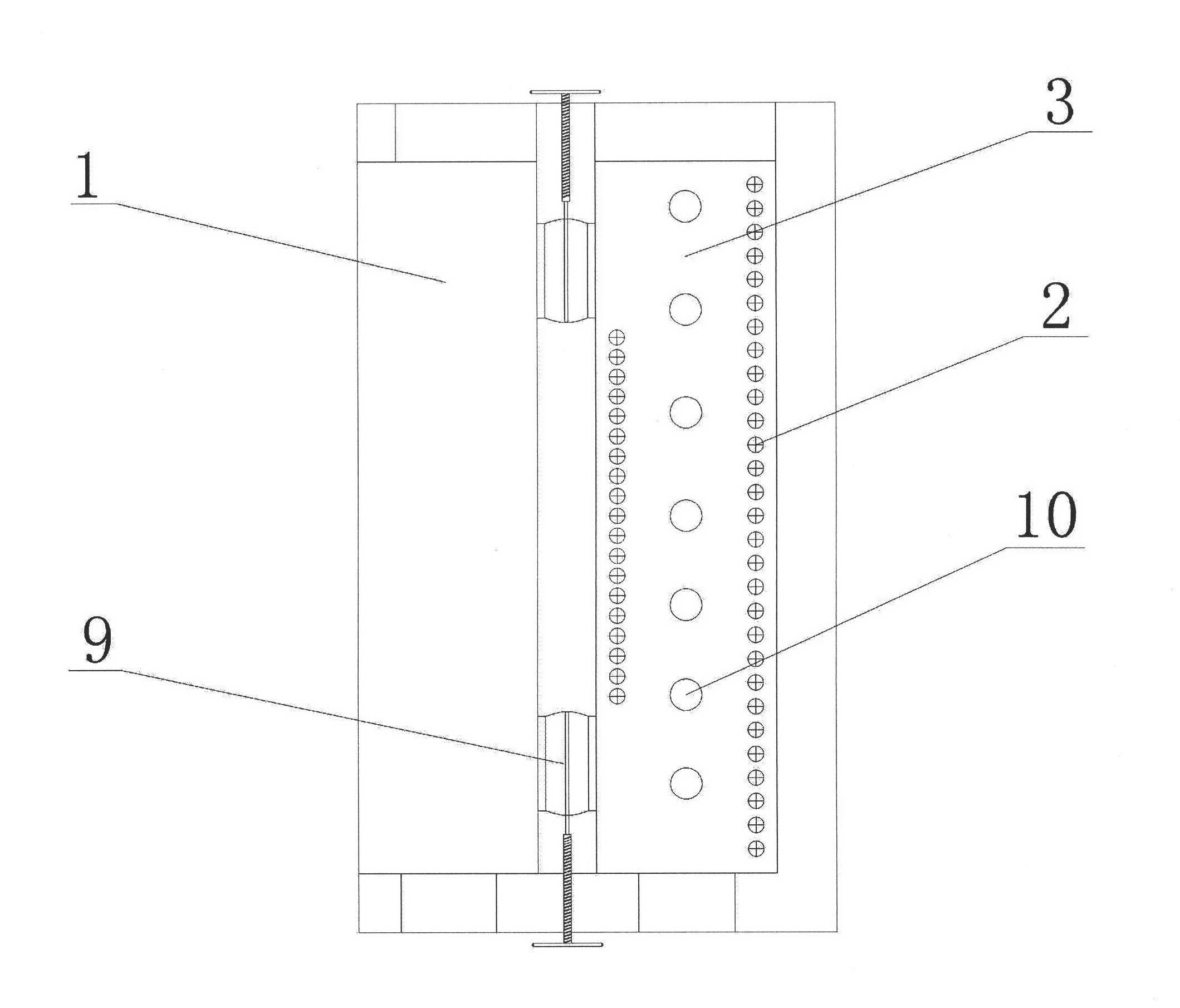

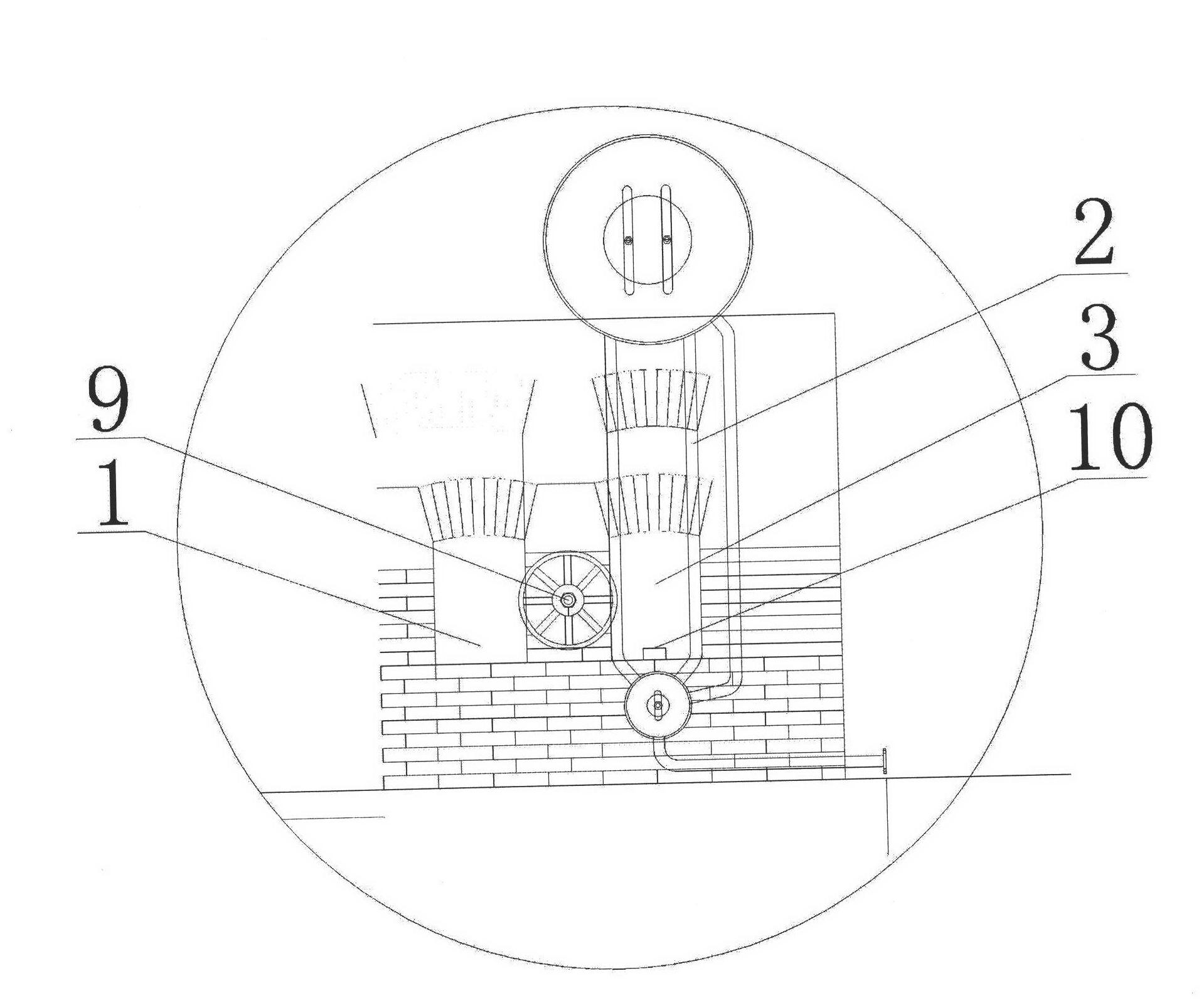

[0011] When the activation furnace is normally ignited, the adjustable gate 9 between the main combustion chamber 1 and the auxiliary combustion chamber 3 is first closed, and the adjustable gate 9 can be properly opened when the temperature of the main combustion chamber 1 reaches the ignition point of the combustible gas. The heat exchanger 7 installed in the flue at the bottom of the heat storage tank of the activation furnace heats the soft water in the soft water storage tank 5 by natural circulation, and the heated soft water is pumped into the evaporator installed in the auxiliary combustion chamber 3 through the frequency conversion constant pressure pump 6 In the network pipe 2, by adjusting the adjustable shutter 9, an appropriate amount of combustible gas is sent into the secondary combustion chamber 3, and the air supply pipe 10 can be adjusted to control the amount of air required for combustible gas combustion to enter the secondary combustion chamber 3, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com