Preparation method of millimeter activated carbon beads

An activated carbon and millimeter-scale technology, which is applied in the field of preparing activated carbon pellets, can solve the problems of undiscovered polyacrylonitrile-based millimeter-scale carbon pellets, and achieve the effects of low cost, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

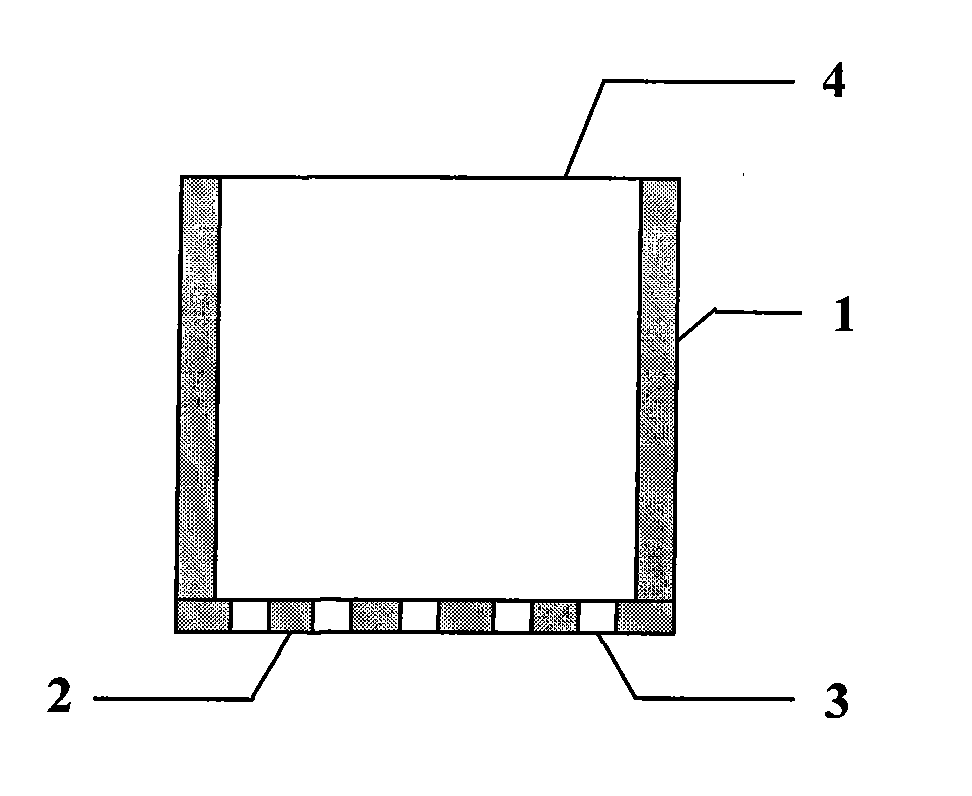

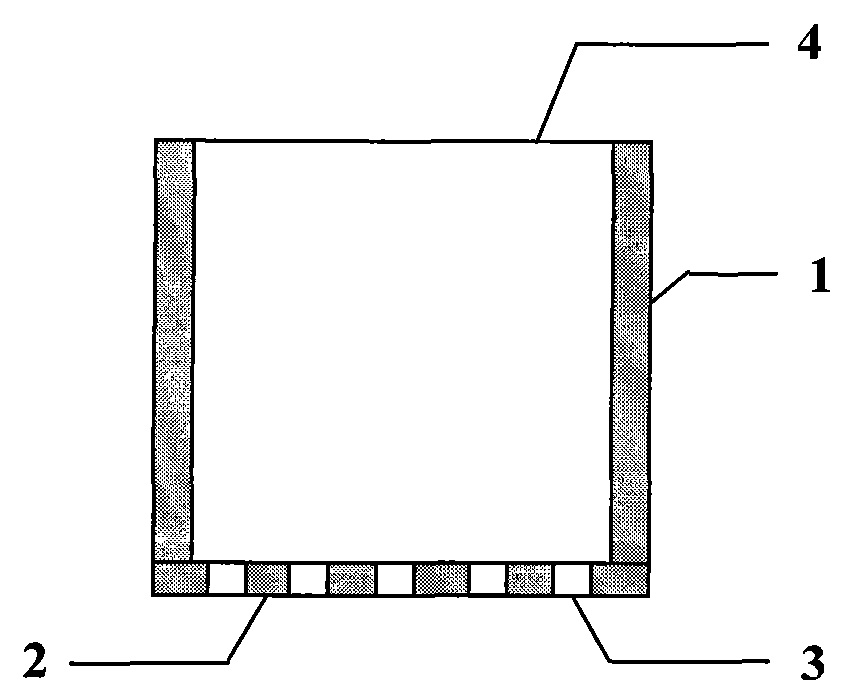

[0026] Fully dissolve 10 g of homemade acrylonitrile in 100 mL of industrial dimethyl sulfoxide (DMSO). Then the obtained solution is gradually transferred to the squeezer, and the height of the liquid level in the squeezer is controlled to 5 cm. Among them, the bottom of the squeezer is a squeezing plate 2 with small holes 3, the thickness of which is about 3mm, the diameter of the small holes is 2.5mm, and the hole pitch is 10mm. The distance between the squeezing plate 2 at the bottom of the squeezer and the liquid surface of the water bath is 10 cm. The solution was dropped into a 60°C water bath to obtain a spherical polyacrylonitrile-based resin. Then put it into a tubular heating furnace, heat up to 200°C at a rate of 2°C / min, keep it for 1h, then under the protection of nitrogen, continue to heat up to 800°C, keep it for 1h, and then pass in water vapor for activation for 30min, after natural cooling A millimeter-scale activated carbon pellet with a diameter of about ...

Embodiment 2

[0028] Fully dissolve 10 g of homemade acrylonitrile in 250 mL of industrial dimethyl sulfoxide (DMSO). Then the obtained solution is gradually transferred to the squeezer, and the height of the liquid level in the squeezer is controlled to 2 cm. Among them, the bottom of the squeezer is a squeezing plate 2 with small holes 3, the thickness of which is about 3.5mm, the diameter of the small holes is 2.2mm, and the hole pitch is 12mm. The distance between the squeezing plate 2 at the bottom of the squeezer and the liquid surface of the water bath is 15 cm. The solution was dropped into a 50°C water bath to obtain a spherical polyacrylonitrile-based resin. Then put it into a tubular heating furnace, heat up to 300°C at a rate of 5°C / min, keep it for 3h, then under the protection of nitrogen, continue to heat up to 1000°C, keep it for 2h, then pass in water vapor for activation for 40min, after natural cooling A millimeter-sized activated carbon pellet with a diameter of about 1...

Embodiment 3

[0030] 10 g of commercial polyacrylonitrile was fully dissolved in 500 mL of industrial dimethyl sulfoxide (DMSO). Then the obtained solution is gradually transferred to the squeezer, and the height of the liquid level in the squeezer is controlled to 3 cm. Among them, the bottom of the squeezing device is a squeezing plate 2 with small holes 3, the thickness of which is about 4mm, the diameter of the small holes is 1.5mm, and the hole distance is 14mm. The distance between the squeezing plate 2 at the bottom of the squeezer and the liquid surface of the water bath is 20 cm. The solution was dropped into a 70°C water bath to obtain a spherical polyacrylonitrile-based resin. Then put it into a tubular heating furnace, heat up to 250°C at a rate of 1°C / min, keep it for 5h, then under the protection of nitrogen, continue to heat up to 900°C, keep it for 3h, then pass in water vapor for activation for 20min, after natural cooling A millimeter-level activated carbon pellet with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com