Preparation method of hierarchical pore carbon-based catalyst for catalytic reforming of coal tar

A technology of carbon-based catalysts and catalytic upgrading, applied in the direction of physical/chemical process catalysts, catalytic cracking, chemical instruments and methods, etc., can solve the problems of unfavorable reactant diffusion active site contact, complex production process, high preparation cost, etc. Achieve the effects of low preparation cost, simple production process and increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

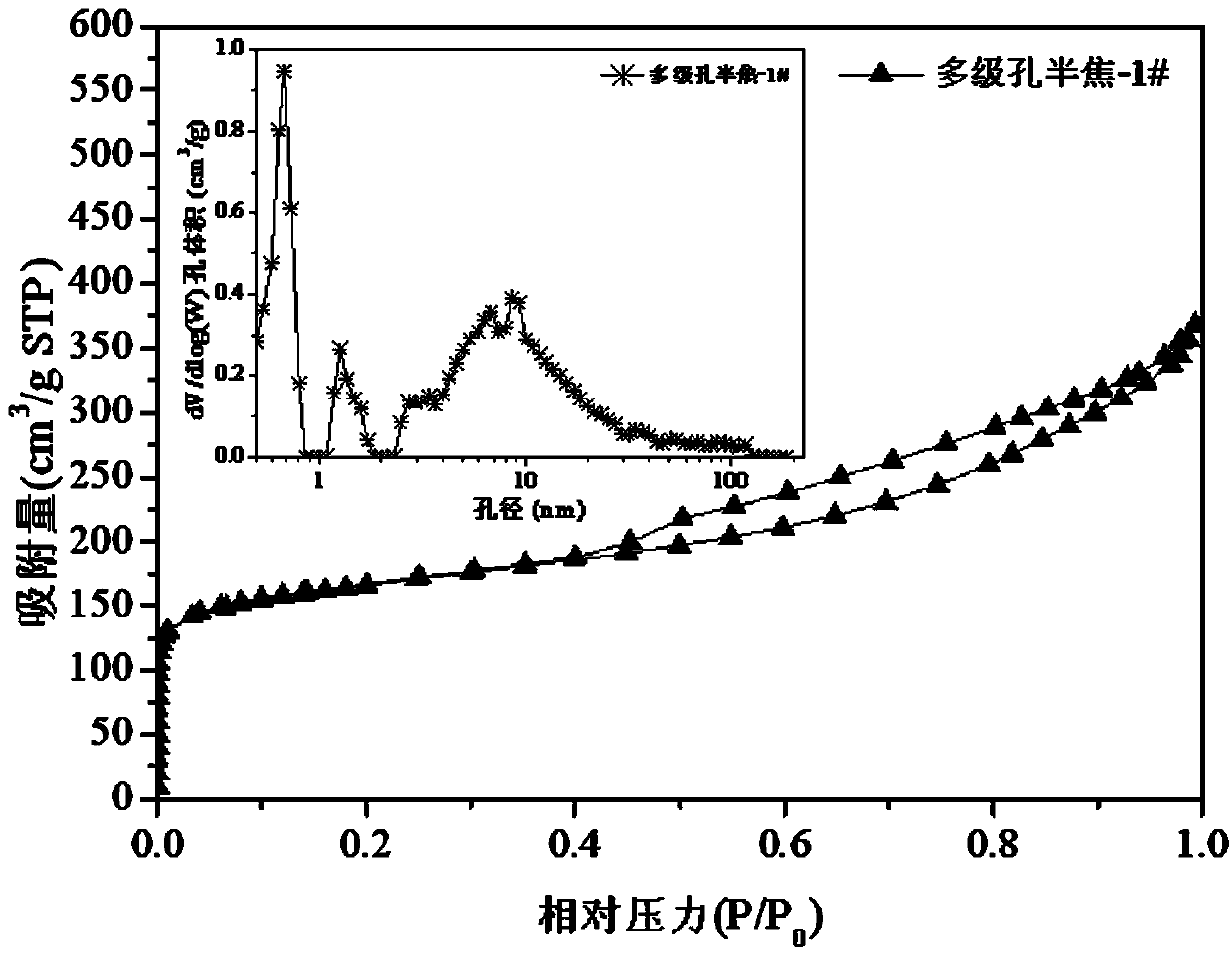

Embodiment 1

[0036] (1) The long-flame coal Wucaiwan coal in the Wucaiwan area of Xinjiang was selected as the raw material. After the coal sample was crushed, ground and sieved, the sample with a particle size of less than 0.178mm was selected for the experiment.

[0037] (2) The raw coal of Wucai Bay is treated with acid elution and demineralization. Stir 60g of coal sample with 600mL of hydrochloric acid with a concentration of 6mol / L at 25°C for 12h, filter, wash and dry, then soak the coal sample with 600mL of hydrofluoric acid with a concentration of 7.6mol / L at 25°C Stir for 12 hours, filter, wash and dry to obtain demineralized Wucaiwan coal.

[0038] (3) Weigh 11g demineralized Wucaiwan coal and 0.7793g Ca(NO 3 ) 2 4H 2 O was mixed in a beaker, and deionized water was added to submerge the sample. After stirring at 25 °C for 12 h, the resulting mixture was dried at 70 °C to obtain demineralized Wucaiwan coal loaded with calcium nitrate.

[0039] (4) Put the demineralized Wuc...

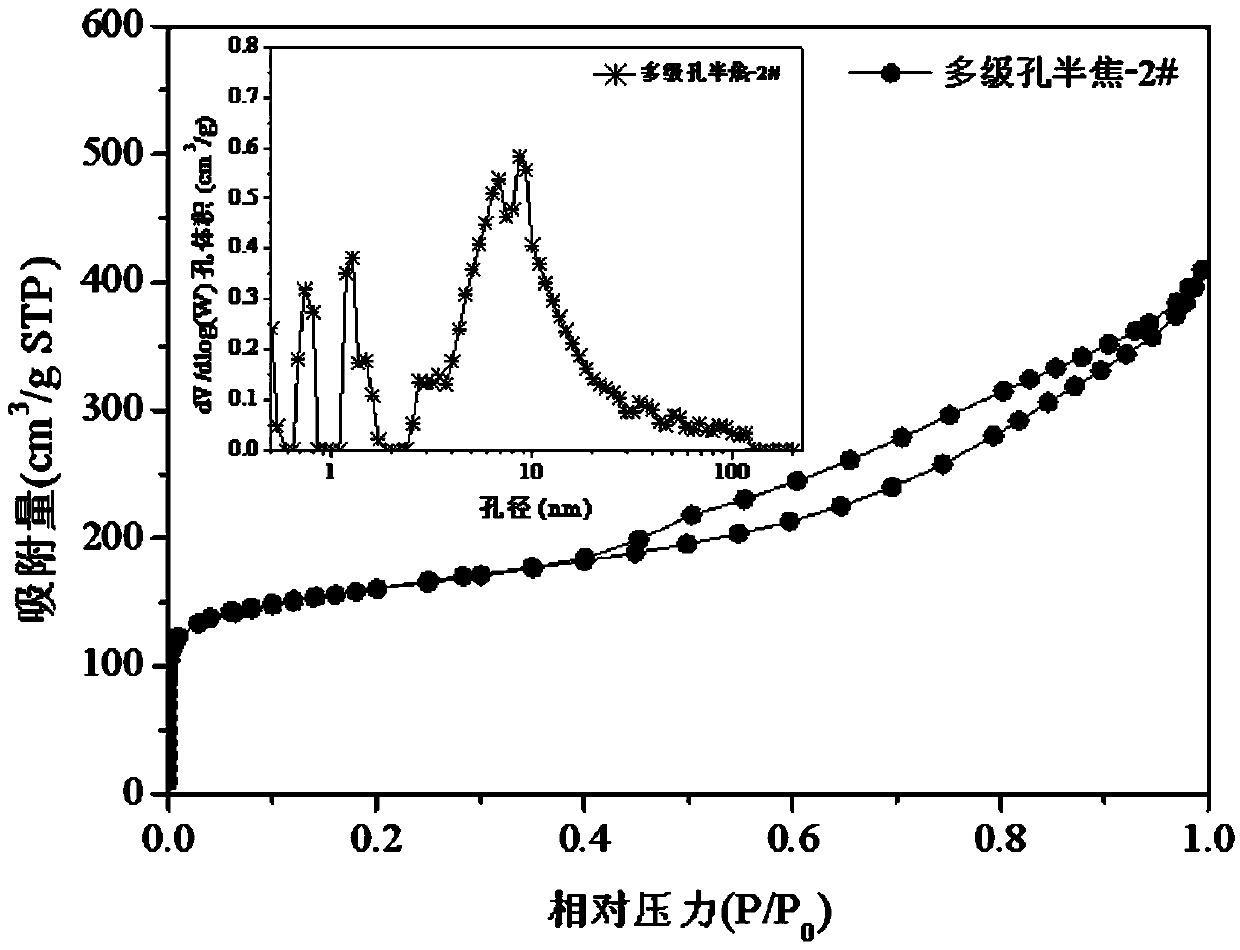

Embodiment 2

[0044] (1) The long-flame Yining coal in the Yining area of Xinjiang was selected as the raw material. After the coal sample was crushed, ground, and sieved, the sample with a particle size of less than 0.178 mm was selected for the experiment.

[0045] (2) Carry out acid elution mineral treatment on Yining raw coal. Stir 40 g of coal sample with 400 mL of hydrochloric acid with a concentration of 6 mol / L at 25°C for 12 hours, filter, wash, and dry, then soak the coal sample washed with hydrochloric acid and 400 mL of hydrofluoric acid with a concentration of 7.6 mol / L at 25 °C Stir at ℃ for 12 hours, filter, wash and dry to obtain demineralized Yining coal.

[0046] (3) Weigh 9g of demineralized Yining coal and 0.4757g of Ca(CH 3 COO) 2 ·H 2 O was mixed in a beaker, and deionized water was added to submerge the sample. After stirring at 25 °C for 12 h, the resulting mixture was dried at 70 °C to obtain demineralized Yining coal loaded with calcium acetate.

[0047] (4) ...

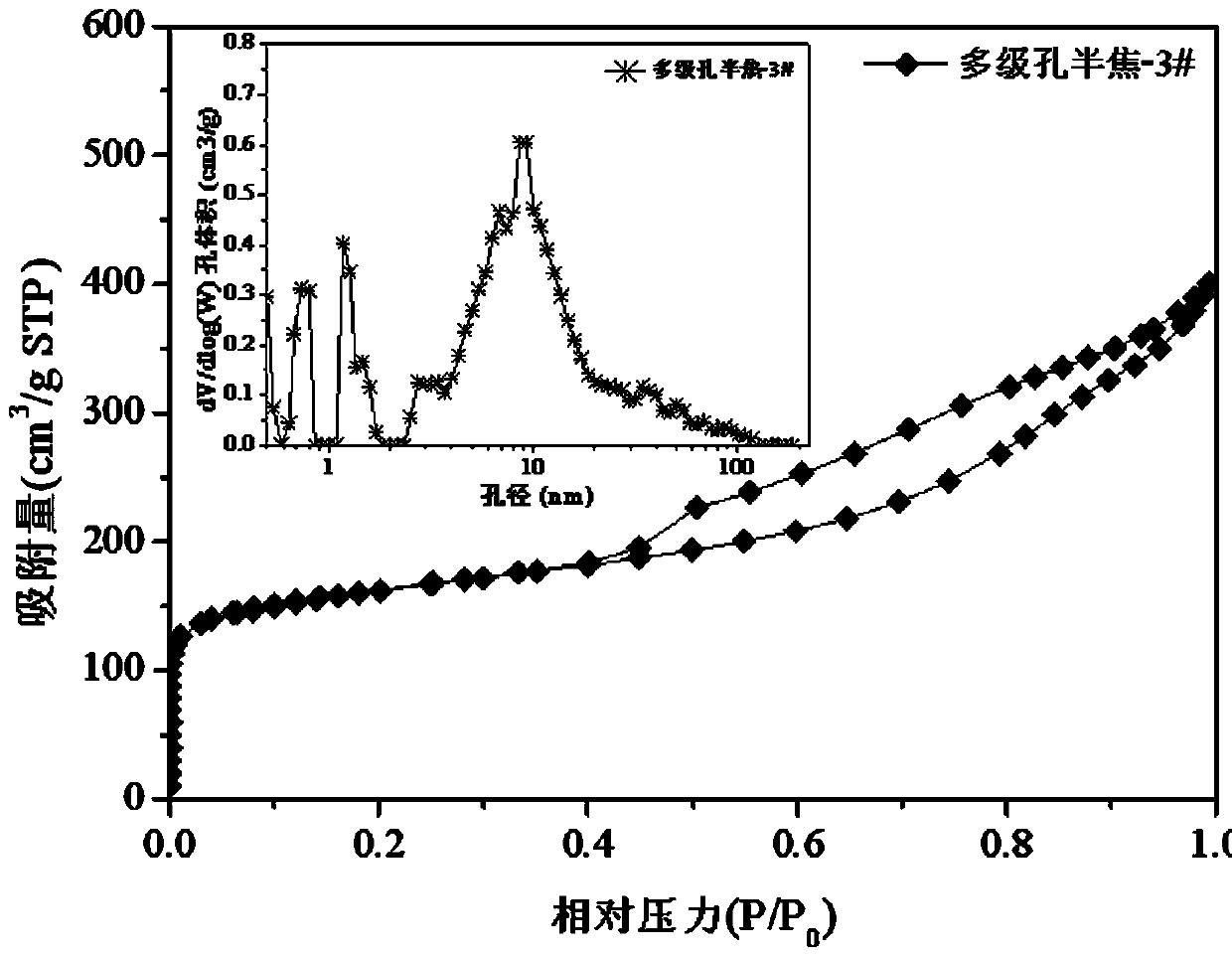

Embodiment 3

[0053] (1) The long-flame coal Wucaiwan coal in the Wucaiwan area of Xinjiang was selected as the raw material. After the coal sample was crushed, ground and sieved, the sample with a particle size of less than 0.178mm was selected for the experiment.

[0054] (2) The raw coal of Wucai Bay is treated with acid elution and demineralization. Stir 60g of coal sample with 600mL of hydrochloric acid with a concentration of 6mol / L at 25°C for 12h, filter, wash and dry, then soak the coal sample with 600mL of hydrofluoric acid with a concentration of 7.6mol / L at 25°C Stir for 12 hours, filter, wash and dry to obtain demineralized Wucaiwan coal.

[0055] (3) Weigh 12g of demineralized Wucaiwan coal and 0.2223g of Ca(OH) 2 Mix in a beaker, add deionized water to immerse the sample, stir at 25°C for 12h, and dry the resulting mixture at 70°C to obtain demineralized Wucaiwan coal loaded with calcium hydroxide.

[0056] (4) The demineralized Wucaiwan coal loaded with calcium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com