Energy-saving activating reaction furnace for preparing special activated carbon for sewage treatment

A technology for sewage treatment and reaction furnace, applied in inorganic chemistry, chemical industry, carbon compounds, etc., can solve the problems of large area, single product performance, high unit cost, and achieve energy saving, high cost and low performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

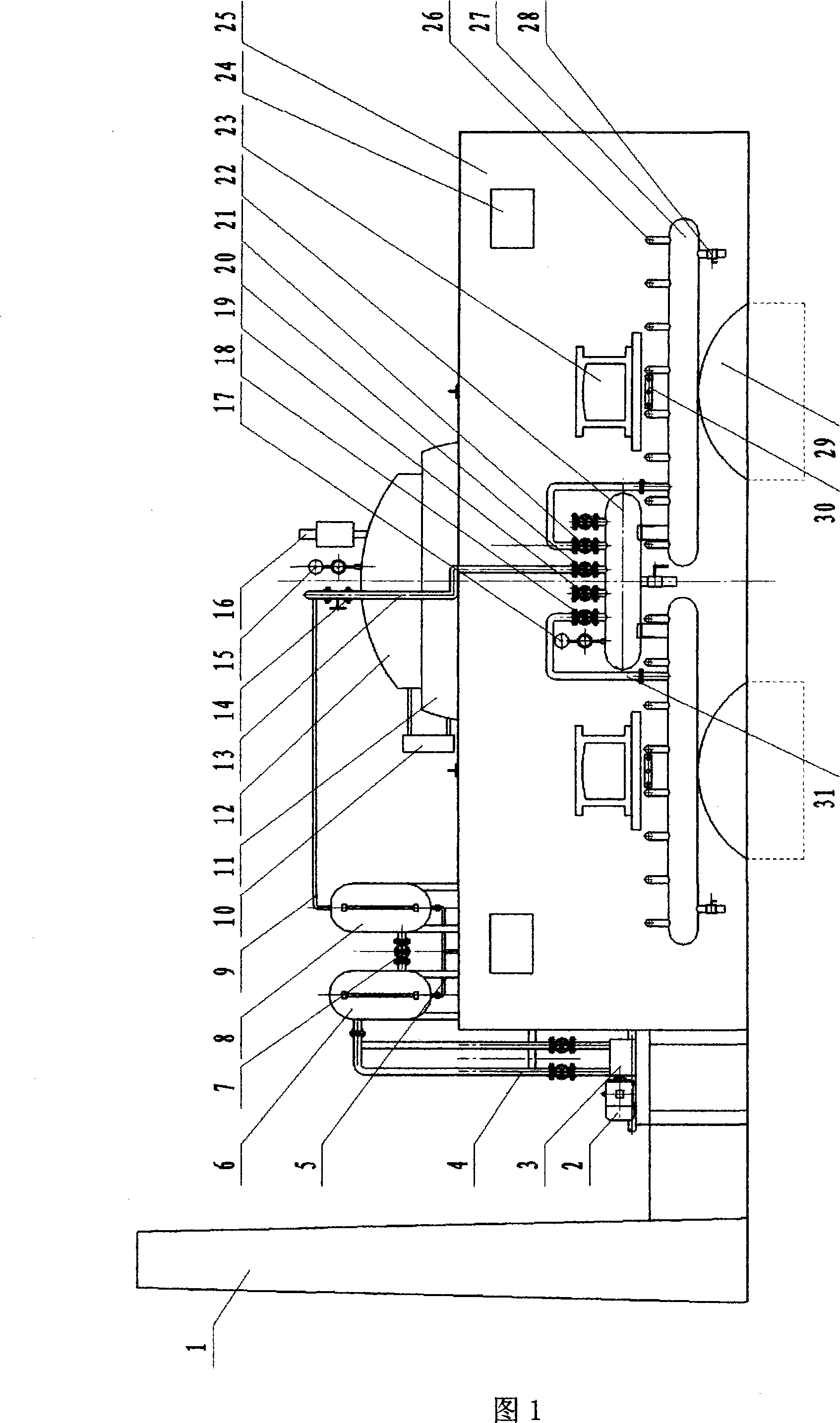

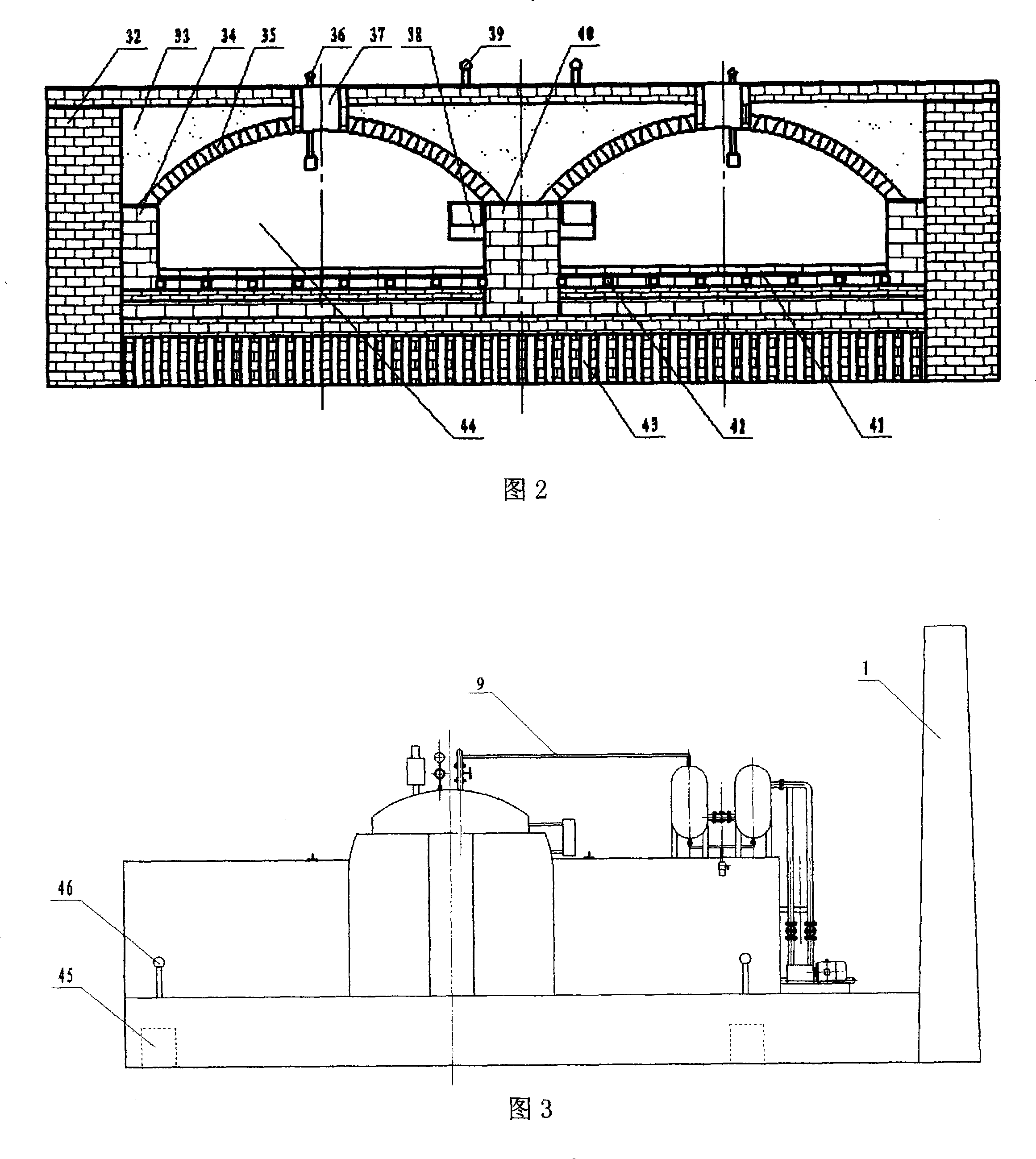

[0012] Body of furnace (25 among Fig. 1) is made of hearth refractory brick (34 among Fig. 2), outer wall of furnace (32 among Fig. 2), is provided with thermal insulation layer (33 among Fig. 2) in the middle. Firstly, the motor (2 in Fig. 1) drives the booster water pump (3 in Fig. 1) to supply water to the steam generator (12 in Fig. 1), and the carbonization raw material is added to the furnace from the feeding port (37 in Fig. 2) (Fig. 44 in 2), ignite the charcoal raw material and allow it to spontaneously ignite, open the upper flue control gate (39 in Figure 2) to generate steam through the regenerator (11 in Figure 1) thermal steam generator (12 in Figure 1), and The secondary heat storage is returned to the combustion chamber (43 in Figure 2) for heat storage, and the steam is delivered from the steam delivery pipeline (13 in Figure 1) to the storage cylinder (22 in Figure 1), and the steam is distributed to the distribution cylinder through the main control valve (20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com