Technology for regeneration of waste activated carbon for adsorbing saturated chlorohydrocarbon organic compounds and treatment of waste gas thereof

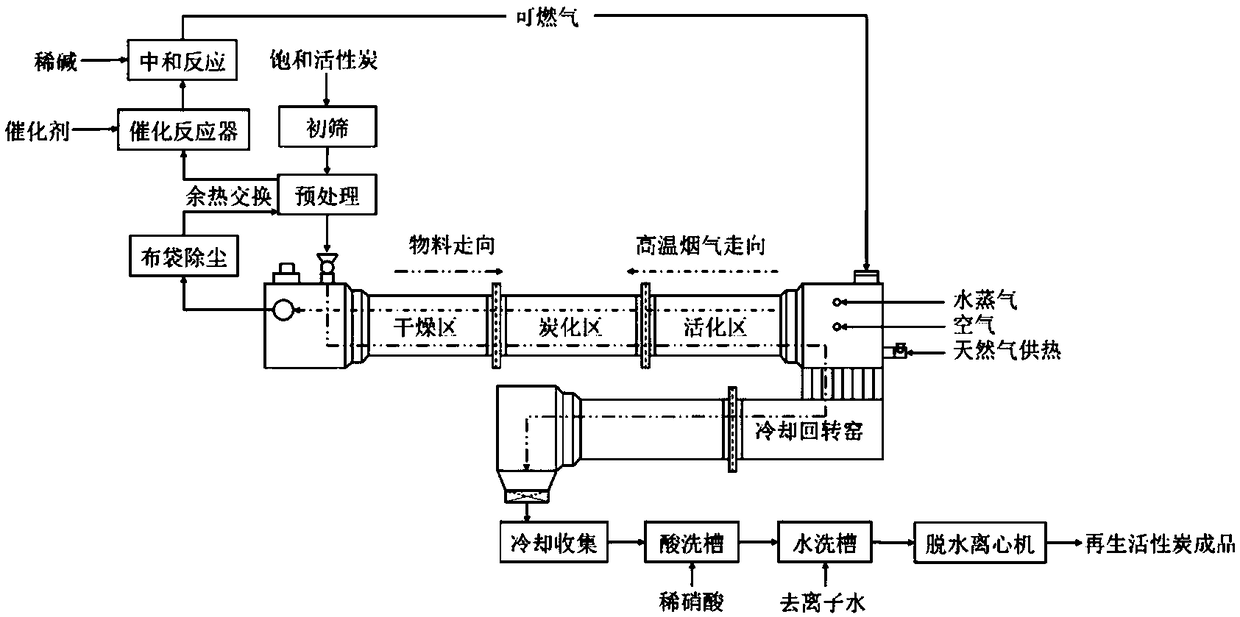

A technology for treating organic compounds and waste gas, which can be used in filter regeneration, petroleum industry, combustible gas purification, etc. It can solve problems such as difficulty in completely restoring the original performance of activated carbon, secondary pollution of the atmospheric environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Activated carbon saturated with dichloromethane adsorption is selected as the raw material. The diameter of the rotary kiln used is 2000mm, the length of the cylinder is 45000mm, the rotation speed is 0.5r / min, and the inclination of the cylinder is 2°.

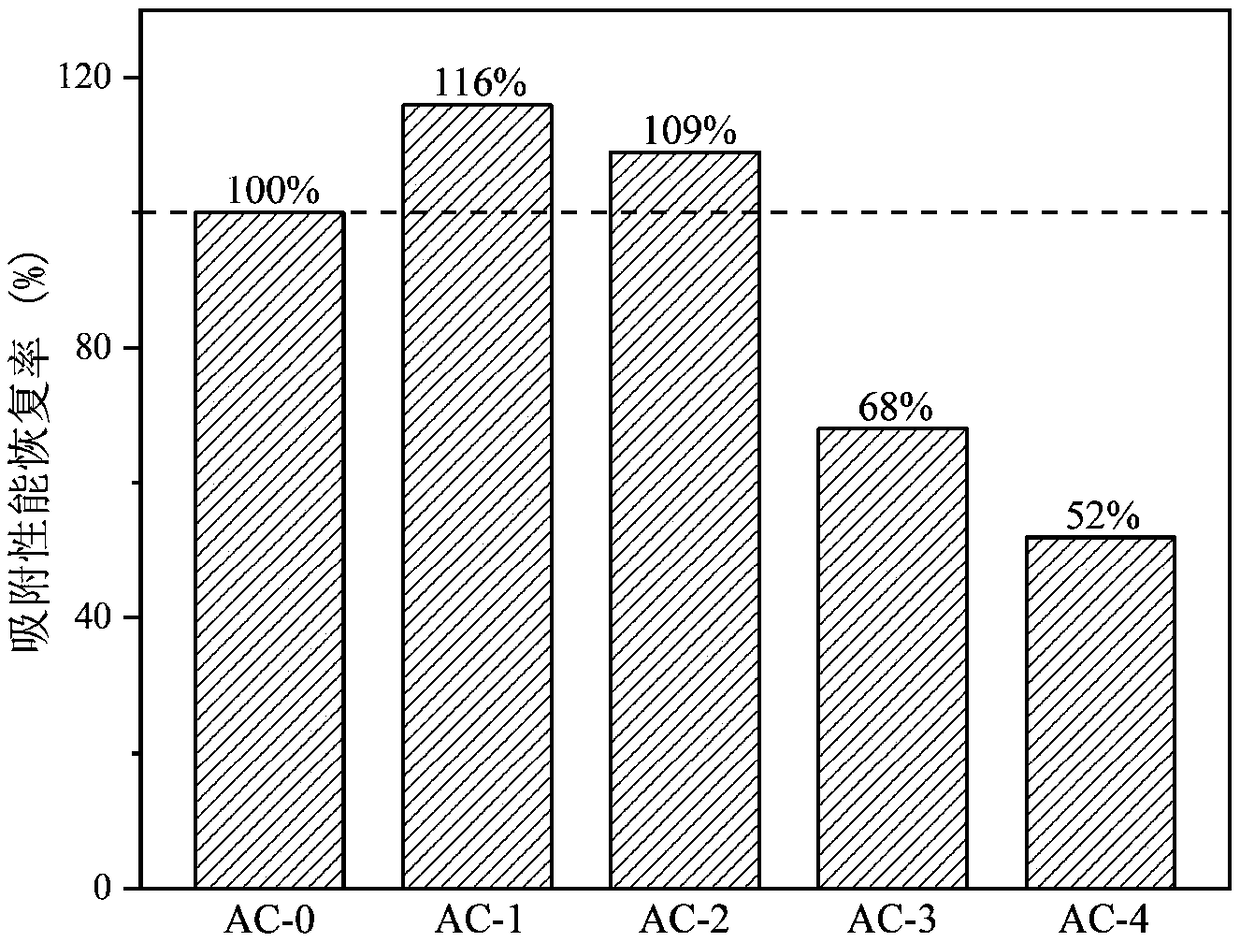

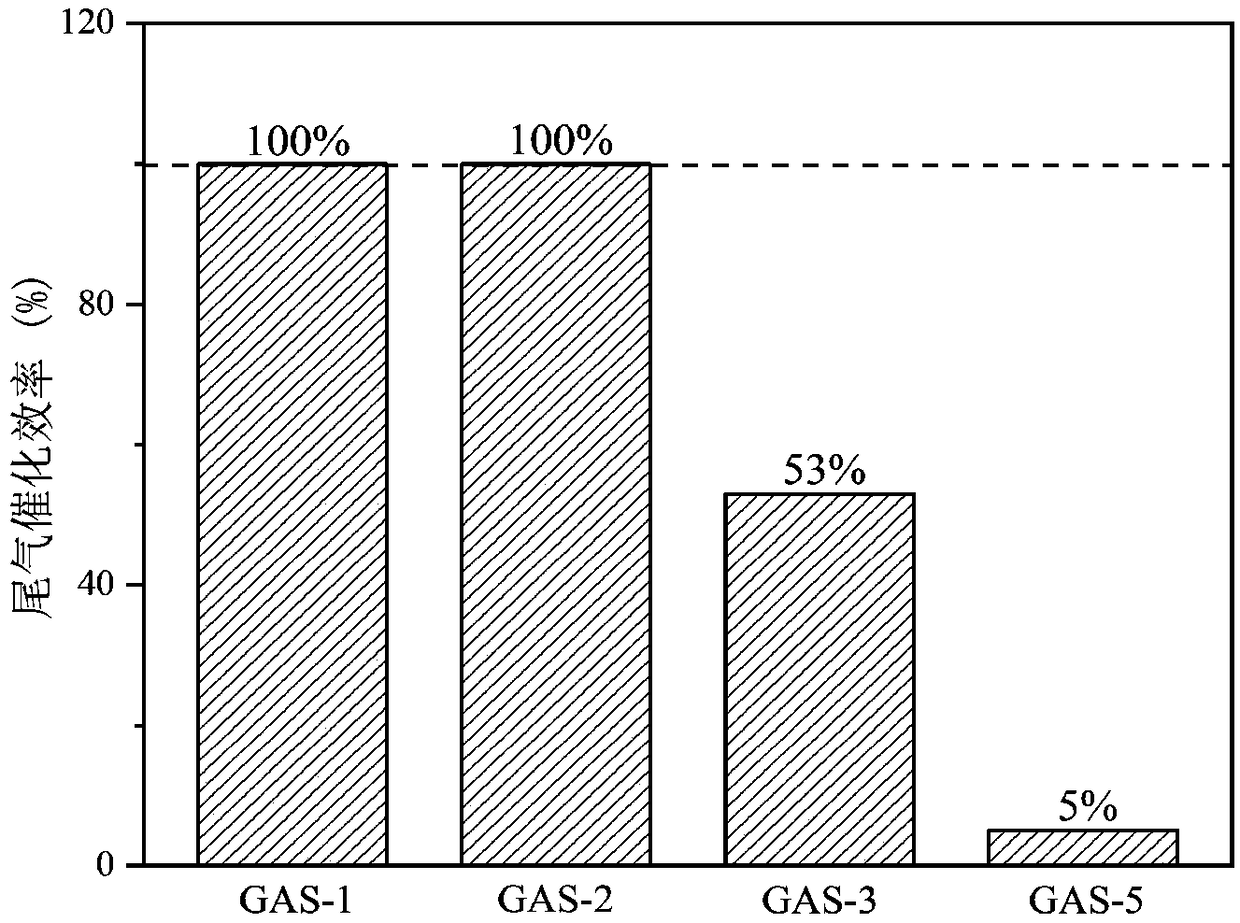

[0054] Sieve the waste activated carbon that absorbs dichloromethane to saturation, and then send it to the dryer through the conveyor belt device for pre-drying for 0.5h. Start the rotary kiln, ignite and heat up, and start filling when the temperature of the kiln tail rises to about 200°C. The pretreated activated carbon enters the kiln barrel through the material settling chamber at the kiln tail. With the continuous rotation of the barrel and the action of the activated carbon's own gravity, the activated carbon passes through the low-temperature drying zone, the medium-temperature pyrolysis carbonization zone and the high-temperature activation zone in sequence. Among them, the temperature in the low-temperature z...

Embodiment 2

[0057]The difference from Example 1 is only the difference in the selection of activated carbon. In embodiment 2, activated carbon saturated with trichlorethylene adsorption will be used as the regeneration object. Under the same operating conditions, another common waste activated carbon in the industry will be tested for regeneration. The regenerated activated carbon is denoted as AC-2. Record its exhaust gas as GAS-2.

Embodiment 3

[0059] The only difference from Example 1 is whether to add activation gas. In embodiment 3, water vapor will no longer be passed into the kiln body as activation gas in addition. CO in flue gas after combustion of natural gas only 2 and H 2 O and the water evaporated from saturated activated carbon are activated by heating. Other conditions remain unchanged, the regenerated activated carbon is recorded as AC-3, and its tail gas is recorded as GAS-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com