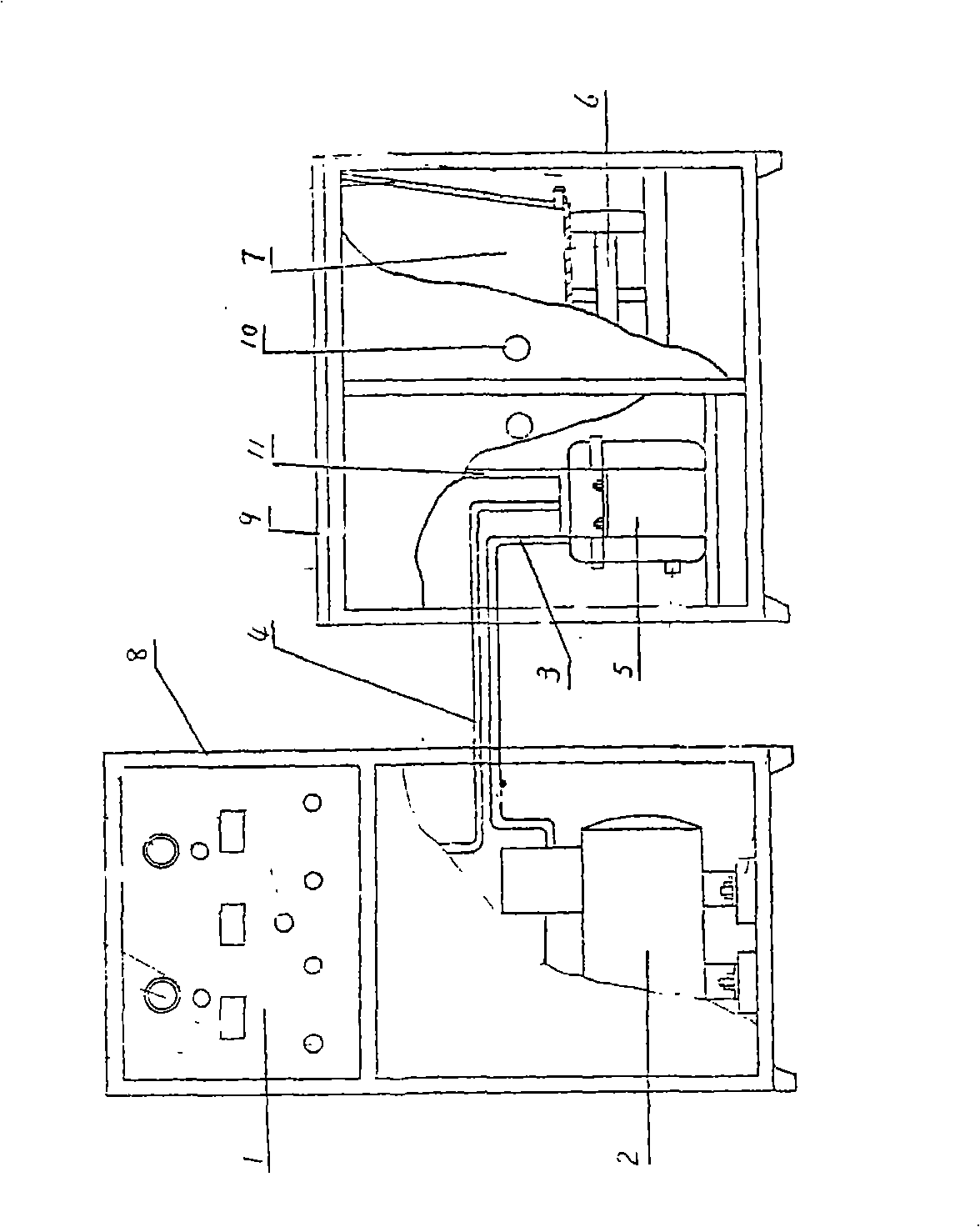

Process and equipment for high-temp and high-pressure spray dyeing of colour fabrics

A high-pressure jet, textile technology, applied in the field of printing and dyeing, can solve the problems of large waste of dyes, large waste of energy, waste of dyes, etc., and achieve the effect of shortening the dyeing process and time, reducing the cost of printing and dyeing, and high utilization of dyes

- Summary

- Abstract

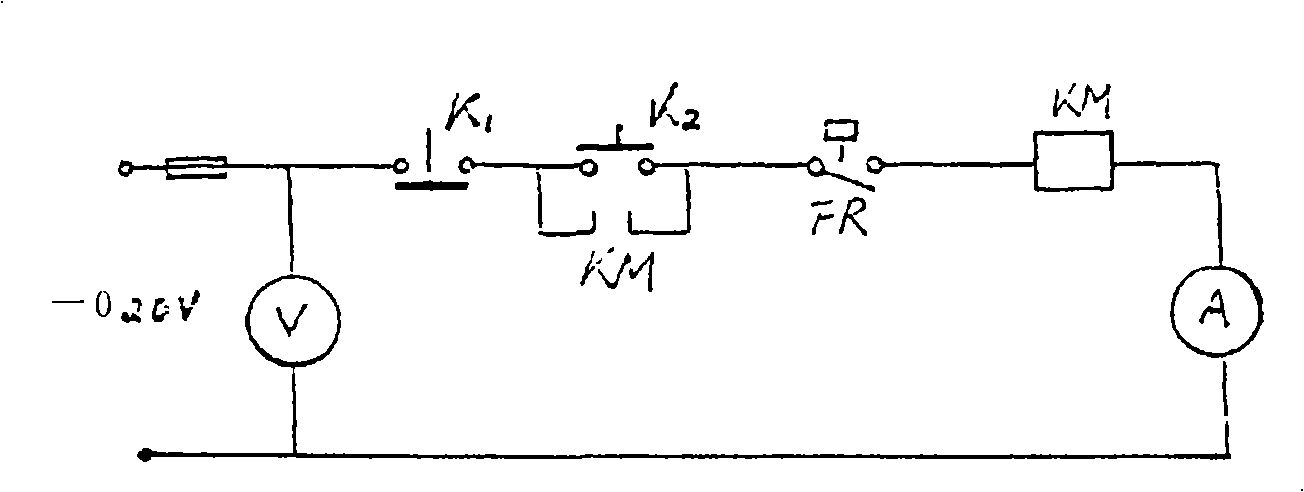

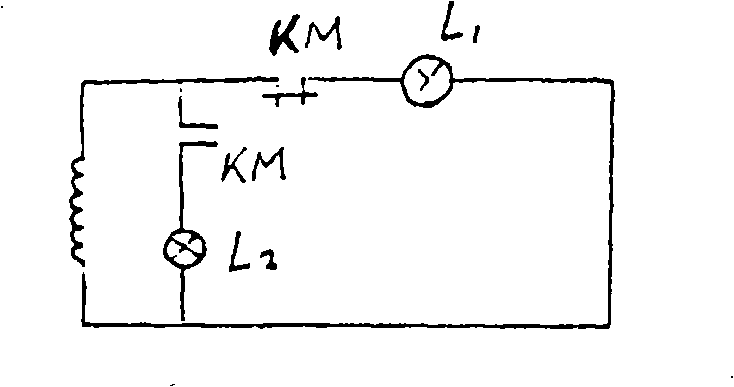

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A semi-new bright blue sweater weighing 500 grams was dyed bright green.

[0025] The dye weight of the above-mentioned brilliant blue sweater according to the calculation formula is:

[0026] 500×1%=5 grams

[0027] If 50% of the color is removed, the weight of the remaining dye is:

[0028] 5X50% = 2.5 grams

[0029] According to the principle of color matching, bright blue and bright yellow are combined into bright green, and the bright yellow dye is taken according to the medium color ratio;

[0030] Dye: Acid Bright Yellow 2G 5g

[0031] Acid Brilliant Blue 2.5g

[0032] Dyeing aid: Glacial acetic acid HAC 50ml

[0033] Leveling Agent 0 10ml

[0034] Diffuser NNO 10ml

[0035] Penetrant JFC 10ml

[0036] Bath ratio: 1:10

[0037] First put the sweater in the steam dyeing room for 10 minutes under normal pressure, then take it out and wait for spray dyeing. Then dissolve the weighed dye with 20~40~C water to make a dye solution, and make a dye solution acc...

Embodiment 2

[0039] A pair of dark gray jeans, 500 grams, dyed into navy blue.

[0040] According to the calculation, it can be obtained that:

[0041] Dye: Direct Fast Blue B2RL 10g

[0042] Dyeing aid: NaCl 200g

[0043] Soda ash 10 grams

[0044] Silky Soap 5ml

[0045] Yuanming powder 5 grams

[0046] Diffuser NNO 10ml

[0047] Penetrant JFC 10ml

[0048] Bath ratio: 1:8

[0049] Clothes steaming bath is the same as that of dissolving dyes as in Example 1, and the dyeing solution is adjusted according to the bath ratio of 1:8. After the various auxiliary agents are dissolved, pour them into the dye vat, stir well, cover and heat, and the rest of the process is the same as in the example. 1 is the same.

Embodiment 3

[0051] A pair of dark gray jeans weighs about 500 grams, faded by 30%, and want to return to the original dark gray,

[0052] According to the calculation, the dye weight of the standard dark gray jeans is

[0053] 5002% = 10 grams

[0054] fade color dye heavy

[0055] 10 grams 30% = 3 grams

[0056] Take Dye: Direct Ash D 3g

[0057] Auxiliary: 50 grams of table salt (NaCl)

[0058] Diffuser NNO 10ml

[0059] Leveling Agent 0 10ml

[0060] Penetrant JFC 10ml

[0061] Bath ratio: 1:10

[0062] Other process embodiment 1 is identical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com