Ultrasonic steam bath cleaning machine for plane oxygen system accessories

An oxygen system and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, drying solid materials, etc., can solve the problems of high consumption of cleaning agents, harm to human health, and long time consumption, etc., to achieve reasonable structure and reduce Effects of waste liquid discharge and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

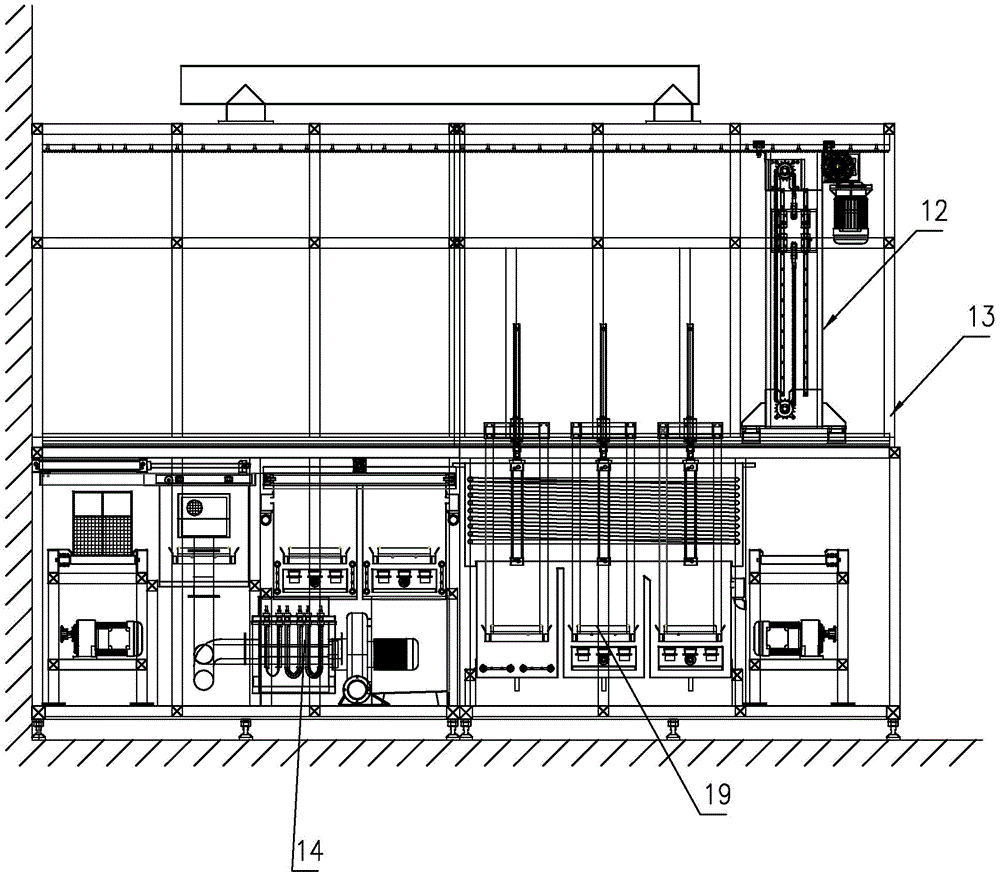

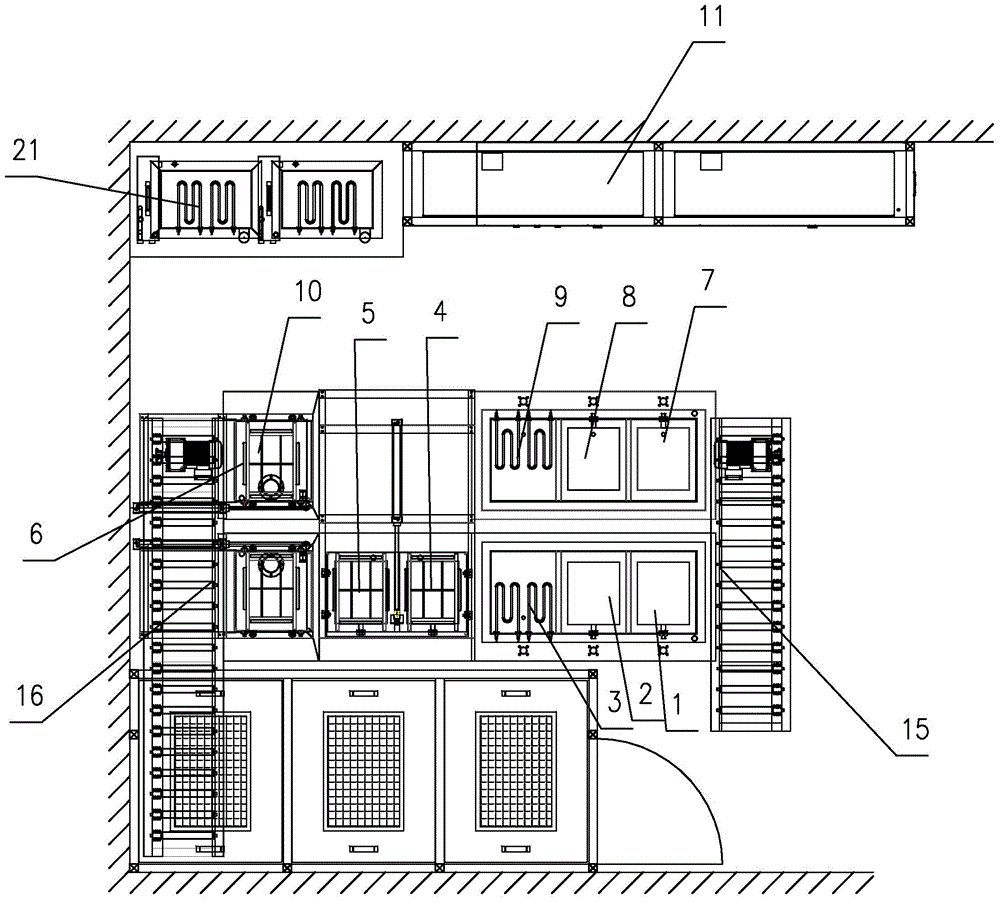

[0024] Such as figure 1 , 2 As shown, it is an ultrasonic steam bath cleaning machine for aircraft oxygen system accessories of the present invention, which includes an electric control device 11, a transmission mechanism 12, a cleaning system located in the same airtight casing 13 and a hot air for drying and cleaning parts. Drying system 14, casing 13 is provided with feed inlet 15 and discharge outlet 16 that can be opened and closed, and the cleaning system includes ultrasonic rough cleaning tank, ultrasonic fine cleaning tank and solvent cleaning tank of steam bath cleaning tank arranged in sequence, Feed inlet 15 is close to the ultrasonic rough cleaning tank, hot air drying system 14 is positioned at the rear of the cleaning system, discharge port 16 is close to hot air drying system 14, and conveying mechanism 12 includes a track that is arranged on the cleaning system and hot air drying system 14, and is located on the track. The manipulator on the top and the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com