High-gloss fine-cleaning combined cleaning technology

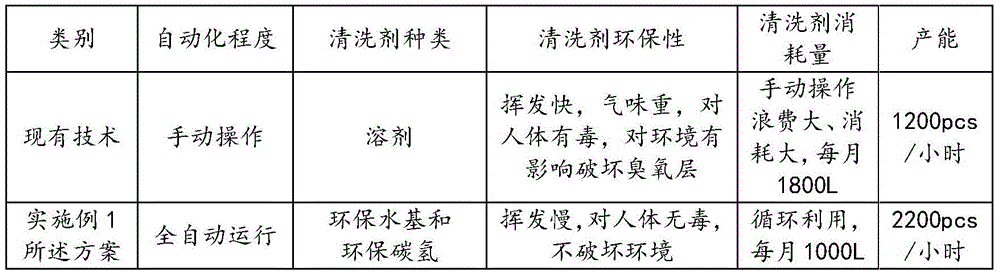

A process and fine cleaning technology, which is applied in the field of high-gloss fine cleaning composite cleaning technology, can solve the problems of insufficient environmental protection of cleaning agents, poor white fog and white spots, etc., and achieve the effect of large market prospects, economic value and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 This example discloses a composite cleaning process for high-gloss fine cleaning. The process includes the following steps in sequence: the first water-based cleaning, the second water-based cleaning, the first vacuum water cutting, and the second vacuum cleaning. Water cutting, the first vacuum hydrocarbon ultrasonic cleaning, the second vacuum hydrocarbon ultrasonic cleaning, steam bath washing and vacuum drying. The cleaning agent used in the water-based cleaning is an environment-friendly water-based cleaning agent, and the cleaning component in the environment-friendly water-based cleaning agent is a surfactant.

[0016] In the first water-based cleaning: liquid setting temperature is 65-75°C; cleaning agent concentration is 5-10%; cleaning time is 60-240s; vacuum degree is -40Kpa.

[0017] In the second water-based cleaning: liquid set temperature is 55-65°C; cleaning agent concentration is 1-3%; cleaning time is 60-240s; vacuum degree is -40Kpa.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com