Process for preparing fine-grain X zeolite

A technology of small crystal grains and zeolite, applied in the field of preparing small crystal grain X zeolite, can solve problems such as low utilization rate of zeolite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

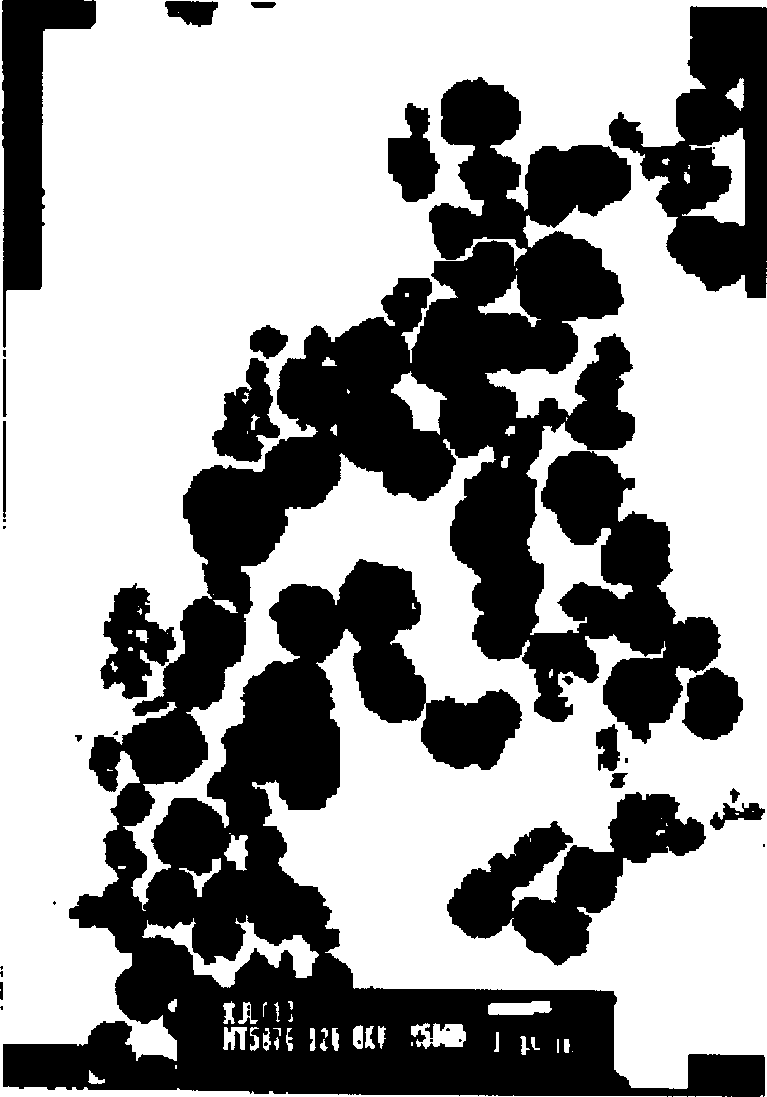

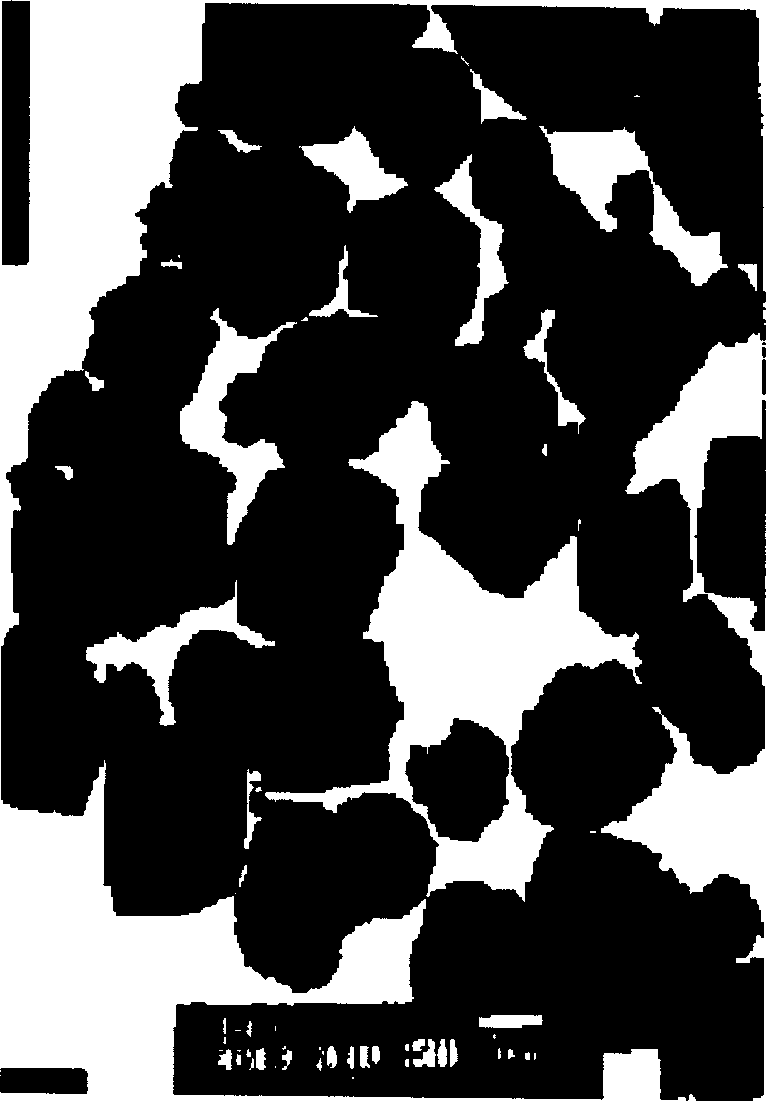

Image

Examples

preparation example Construction

[0008] The method for preparing small grain X zeolite provided by the invention comprises the following steps:

[0009] (1) The silicon-containing compound, aluminum-containing compound, sodium hydroxide and water are (11~18)Na according to the molar ratio 2 O:Al 2 o 3 :(10~17)SiO 2 :(100~350)H 2 Mixed with the ratio of O, aged at 0-10°C to make the directing agent,

[0010] (2) Mix silicon-containing compound, aluminum-containing compound and water with the directing agent prepared in (1) uniformly at 0-10°C, so that the molar composition of the total mixture obtained after adding the directing agent is (2.5-5)Na 2 O:Al 2 o 3 :(3~5)SiO 2 :(40~200)H 2 O,

[0011] (3) crystallize the total mixture prepared in (2) at 80-120° C. for 2-40 hours, wash with water, filter and dry.

[0012] Step (1) of the above-mentioned preparation method is to prepare a directing agent, and the raw material ratio of the directing agent can be prepared by a conventional method, such as pre...

example 1

[0024] The small crystal X zeolite was prepared according to the method described in the present invention.

[0025] (1) Preparation of directing agent

[0026] In 264 ml of water glass (Na 2 O1.384 mol / L, SiO 2 4.644 mol / liter, specific gravity 1.278 kilogram / liter), add 155 milliliters of high alkali sodium metaaluminate solutions (Na 2 O5.226 mol / L, Al 2 o 3 0.529 mol / liter, specific gravity 1.310 kilogram / liter), 28 milliliters of NaOH solution (NaOH 2 (5.306 mol / liter, specific gravity 1.335 kg / liter) and 28 milliliters of water, after stirring uniformly at a speed of 350 rpm, leave it to stand at 10° C. for aging for 18 hours to obtain the directing agent.

[0027] (2) Preparation of X zeolite

[0028] At 5°C, add 374 ml of low-alkali sodium metaaluminate solution (Na 2 O2.581 mol / L, Al 2 o 3 0.9584 mol / L, specific gravity 1.264 kg / L), then add 214 ml of the directing agent prepared in step (1) and 513 ml of water, stir at 350 rpm for 0.5 hour, heat up to 100°C,...

example 2

[0030] Zeolite X was prepared according to the method of Example 1, except that the aging temperature of the directing agent was 5°C for 6 hours, and the low-alkali sodium metaaluminate solution was added to the water glass at 10°C. The performance data of the prepared zeolite are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com