Composite preparing method for improving mechanical property of 6XXX aluminum alloy coiled material

A technology of mechanical properties and aluminum alloys, applied in metal rolling, manufacturing tools, temperature control, etc., can solve problems such as large energy consumption, save costs, reduce aging treatment temperature, reduce cryogenic energy consumption and aging treatment energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

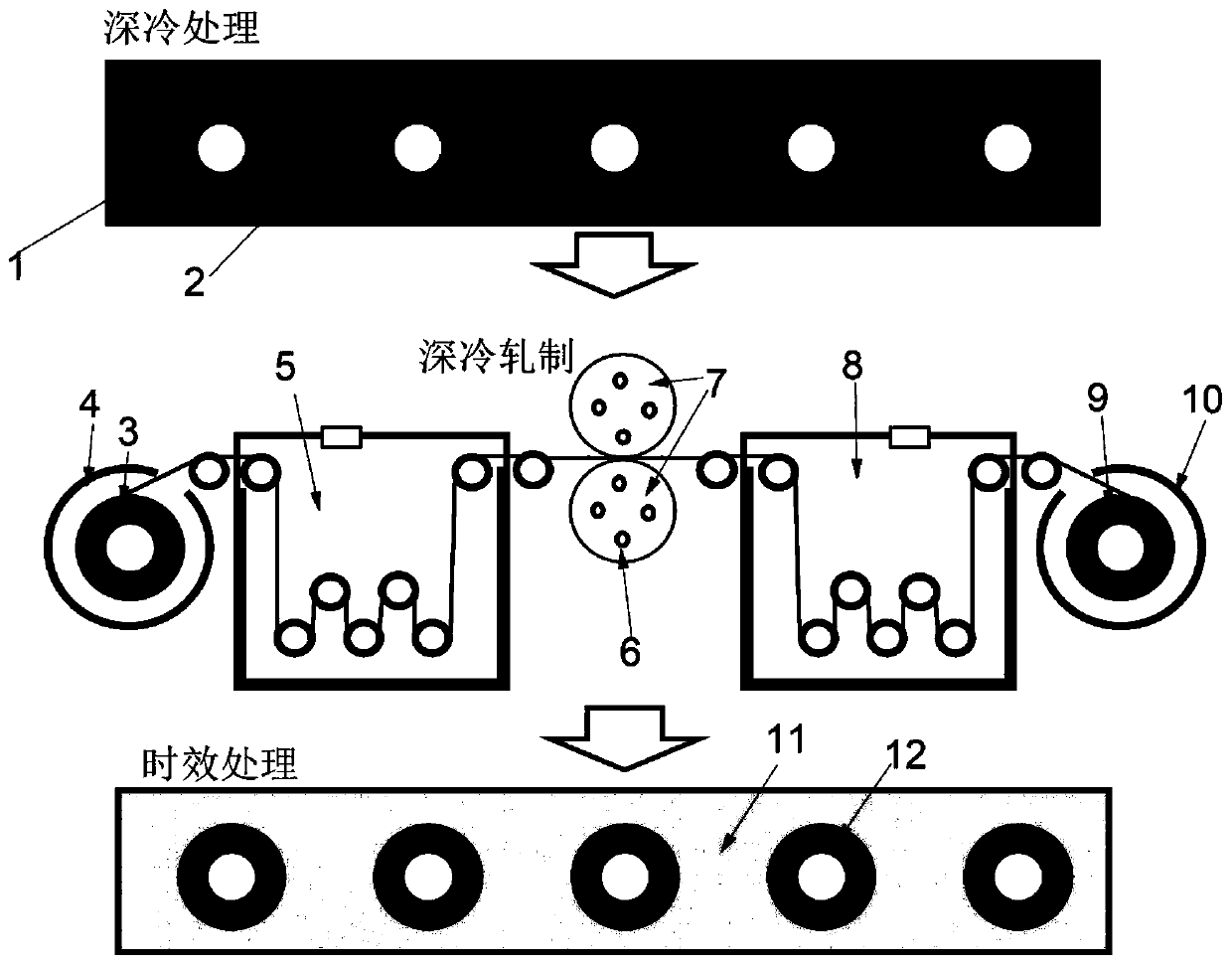

[0020] The invention discloses a compound preparation method for improving the mechanical properties of 6XXX aluminum alloy coils, the main principle of which is to effectively combine fine grain strengthening and precipitation strengthening to realize performance enhancement of 6XXX aluminum alloy coils. Cryogenic rolling is carried out at around -100°C to refine the grain size of 6XXX aluminum alloys, and at the same time, avoid the primary inclusions in 6XXX aluminum alloys at too low temperature to become brittle and form micro-crack sources during rolling deformation. At the same time, aging treatment is carried out at 95-125°C to effectively ensure that the ultra-fine grain structure produced by cryogenic rolling deformation does not recrystallize. However, it reduces the dislocation density in the aluminum alloy and realizes the generation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com