Method for preparing lithium nickel cobalt manganese oxide ternary cathode material in liquid-phase sugar coating and spray drying manners

A technology of nickel-cobalt-lithium-manganese-manganese oxide and cathode materials, which is applied in electrical components, battery electrodes, electrochemical generators, etc., can solve problems such as grain growth, crystal structure damage to transmission channels, and impact on electrical performance, so as to reduce stimulation Dispersion of sexual odor, enhancement of diffusion rate, and enhancement of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

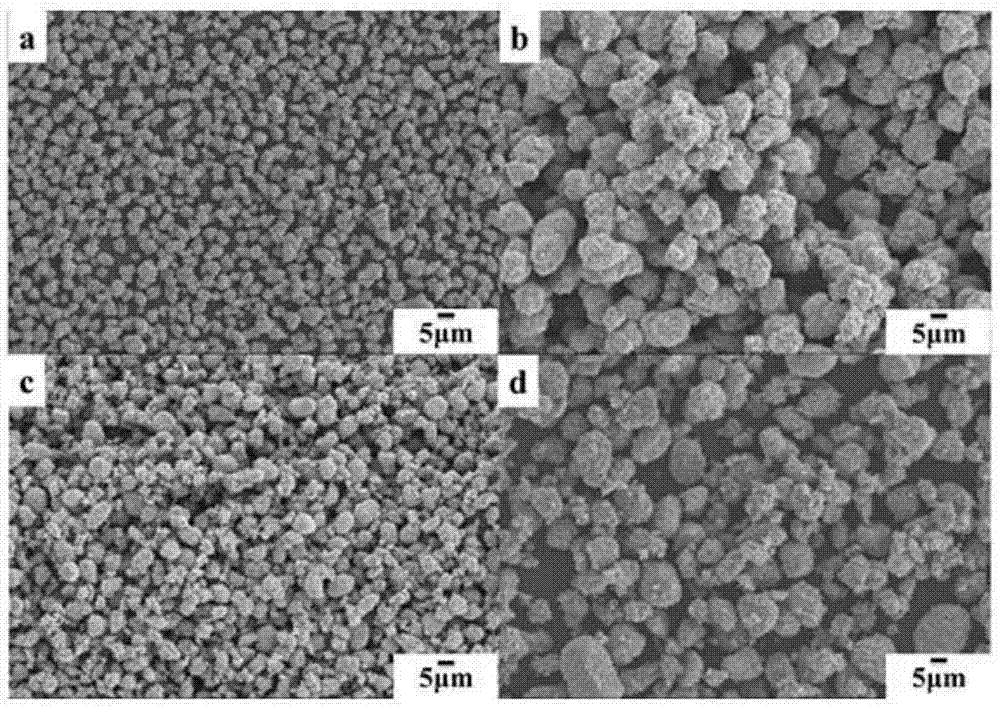

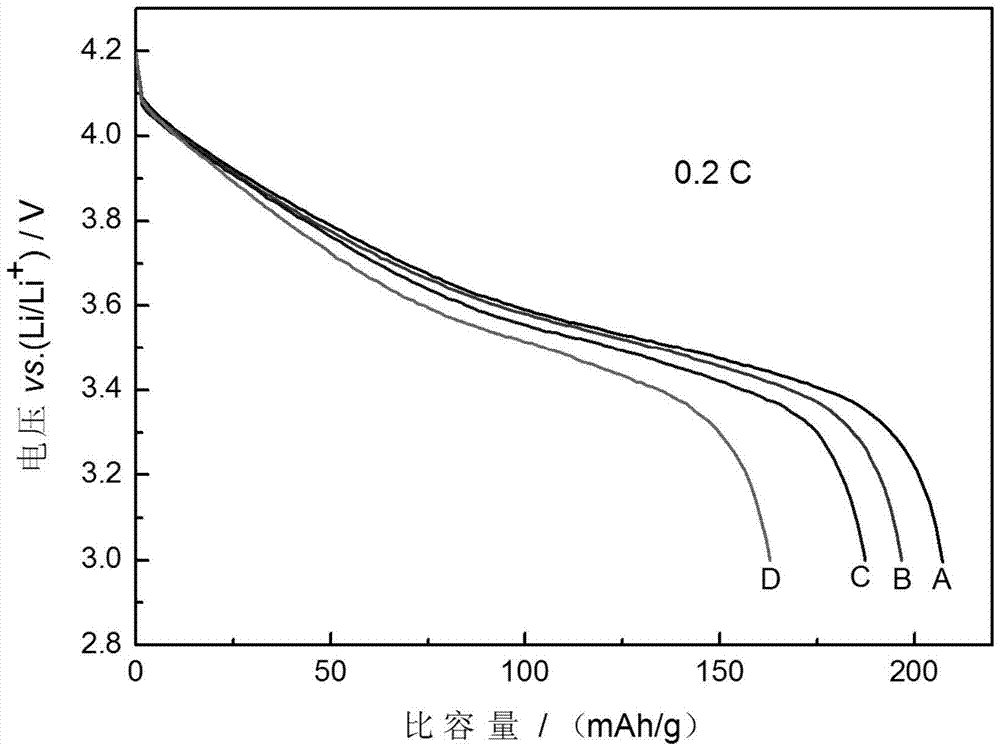

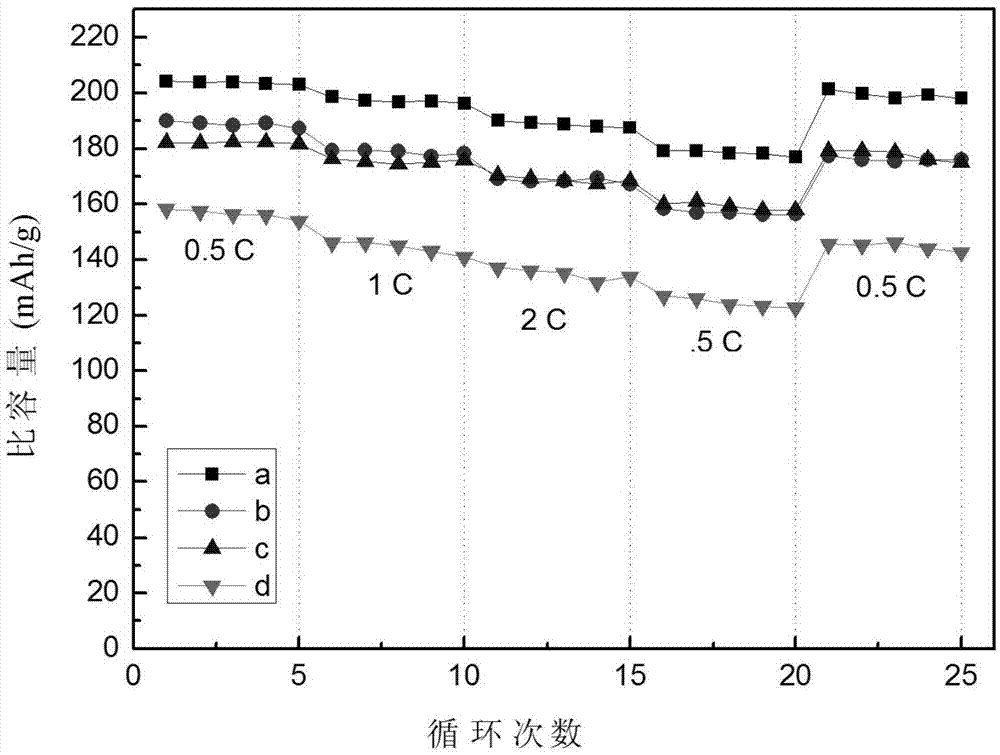

[0022] The sulfate solution of Ni, Co and Mn is mixed uniformly in molar ratio Ni:Co:Mn=Ni:Co:Mn=5:3:2 to obtain a salt solution, and the molar concentration of the sulfate solution of Ni, Co and Mn is equal to It is 2mol / L. Add the ammonia-containing sodium hydroxide solution and the above-mentioned salt solution into the reaction kettle, adjust the feeding speed of the alkali solution, control the pH at 9.5-11.5, and coprecipitate the reaction. After the reaction, wash, filter, and dry to obtain the ternary composite precursor Body (Ni 0.5 co 0.3 mn 0.2 )(OH) 2 . Ammonia-containing sodium hydroxide solution is prepared according to the following method: ammonia water is added to the sodium hydroxide solution, mixed uniformly to obtain, the molar concentration of sodium hydroxide in the finally obtained solution is 4mol / L, NH 3 The mass concentration is 5%.

[0023] Take 1mol lithium hydroxide LiOH, 0.002mol lanthanum oxide La 2 o 3 , 1mol ternary precursor compound (...

Embodiment 2

[0026] The sulfate solution of Ni, Co, and Mn is uniformly mixed according to the molar ratio of Ni:Co:Mn=5:3:2 to obtain a salt solution, and the molar concentration of the sulfate solution of Ni, Co, and Mn is 2mol / L. Add the ammonia-containing sodium hydroxide solution and the above-mentioned salt solution into the reaction kettle, adjust the feeding speed of the alkali solution, keep the pH at 9.5-11.5, and coprecipitate the reaction. After the reaction, wash, filter, and dry to obtain the ternary composite precursor Body (Ni 0.5 co 0.3 mn 0.2 )(OH) 2 . Ammonia-containing sodium hydroxide solution is prepared according to the following method: ammonia water is added to the sodium hydroxide solution, mixed uniformly to obtain, the molar concentration of sodium hydroxide in the finally obtained solution is 4mol / L, NH 3 The mass concentration is 5%.

[0027] Take lithium hydroxide LiOH and ternary precursor compound (Ni 0.5 co 0.3 mn 0.2 )(OH) 2 1 mol each, after mix...

Embodiment 3

[0030] The sulfate solution of Ni, Co, and Mn is uniformly mixed according to the molar ratio of Ni:Co:Mn=5:3:2 to obtain a salt solution, and the molar concentration of the sulfate solution of Ni, Co, and Mn is 2mol / L. Add the ammonia-containing sodium hydroxide solution and the above-mentioned salt solution into the reaction kettle, adjust the feeding speed of the alkali solution, control the pH at 9.5-11.5, and coprecipitate the reaction. After the reaction, wash, filter, and dry to obtain the ternary composite precursor Body (Ni 0.5 co 0.3 mn 0.2 )(OH) 2 . Ammonia-containing sodium hydroxide solution is prepared according to the following method: ammonia water is added to the sodium hydroxide solution, mixed uniformly to obtain, the molar concentration of sodium hydroxide in the finally obtained solution is 4mol / L, NH 3 The mass concentration is 5%.

[0031] Take 1mol lithium hydroxide LiOH, 0.002mol lanthanum oxide La 2 o 3 , 1mol ternary precursor compound (Ni 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com