ZSM-5 composite molecular sieve with a core-shell structure and preparation method and application thereof

A ZSM-5, composite molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, condensation between hydrocarbons and non-hydrocarbons to produce hydrocarbons, etc. and other problems, to achieve the effect of preventing side reactions, improving selectivity, and increasing diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

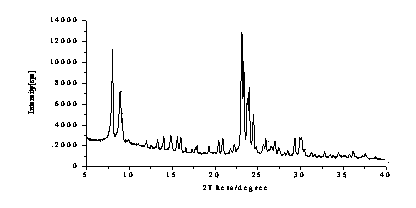

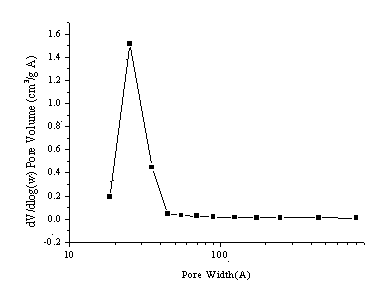

[0025] Add sodium hydroxide and aluminum sulfate to deionized water, weigh tetrapropylammonium bromide and add it to the solution, and after it is completely dissolved, add ZSM-5 molecular sieve (the molar ratio of silicon oxide to aluminum oxide is 25) into the solution After stirring evenly, add CTAB, continue stirring for half an hour, add silica sol, stir evenly, put it into a stainless steel crystallization kettle, crystallize at a constant temperature of 160°C for 60 hours, then wash, dry, and roast to obtain ZSM-5 composite molecular sieve. The properties of molecular sieves are shown in Table 1.

[0026] The molar ratio of the system composed of sodium hydroxide, template agent, water, aluminum source, surfactant and silicon source: 10.0Na 2 O:45SiO 2 :Al 2 o 3 :10.2(TPA) 2 O:CTAB:4722H 2 O, the mass ratio of the added ZSM-5 molecular sieve to the above system is 1:23.

Embodiment 2

[0028] Add sodium hydroxide and aluminum sulfate to deionized water, weigh tetrapropylammonium bromide and add it to the solution, and after it is completely dissolved, add ZSM-5 molecular sieve (the molar ratio of silicon oxide to aluminum oxide is 38) into the solution After stirring evenly, add CTAB, continue stirring for half an hour, add silica sol, stir evenly, put it into a stainless steel crystallization kettle, crystallize at a constant temperature of 170°C for 60 hours, then wash, dry, and roast to obtain ZSM-5 composite molecular sieve. The properties of molecular sieves are shown in Table 1.

[0029] The molar ratio of the system composed of sodium hydroxide, template agent, water, aluminum source, surfactant and silicon source: 9.4Na 2 O:45SiO 2 :Al 2 o 3 :10.2(TPA) 2 O:1.5CTAB:4166H 2 O, the mass ratio of the added ZSM-5 molecular sieve to the above system is 1:27.

Embodiment 3

[0031] Add sodium hydroxide and sodium aluminate to deionized water, weigh tetrapropylammonium bromide and add it to the sodium hydroxide solution, and dissolve ZSM-5 molecular sieve (the molar ratio of silicon oxide to aluminum oxide is 73) Add it into the solution, stir evenly, add CTAB, continue stirring for half an hour, add silica sol, stir evenly, put it into a stainless steel crystallization kettle, crystallize at a constant temperature of 170°C for 48 hours, then wash, dry, and roast to obtain ZSM- 5 Composite molecular sieves. The properties of molecular sieves are shown in Table 1.

[0032] The molar ratio of the system composed of sodium hydroxide, template agent, water, aluminum source, surfactant and silicon source: 9.4Na 2 O:30SiO 2 :Al 2 o 3 :10.2(TPA) 2 O:0.5CTAB:4166H 2 O, the mass ratio of the added ZSM-5 molecular sieve to the above system is 1:23.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com