Composite porous membrane and preparation method thereof

A porous film and adhesive technology, applied in electrical components, circuits, battery pack components, etc., can solve the problems of reducing the porosity of composite separators, affecting lithium ion transport performance, etc., achieving low thermal shrinkage, good cycle characteristics, The effect of excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

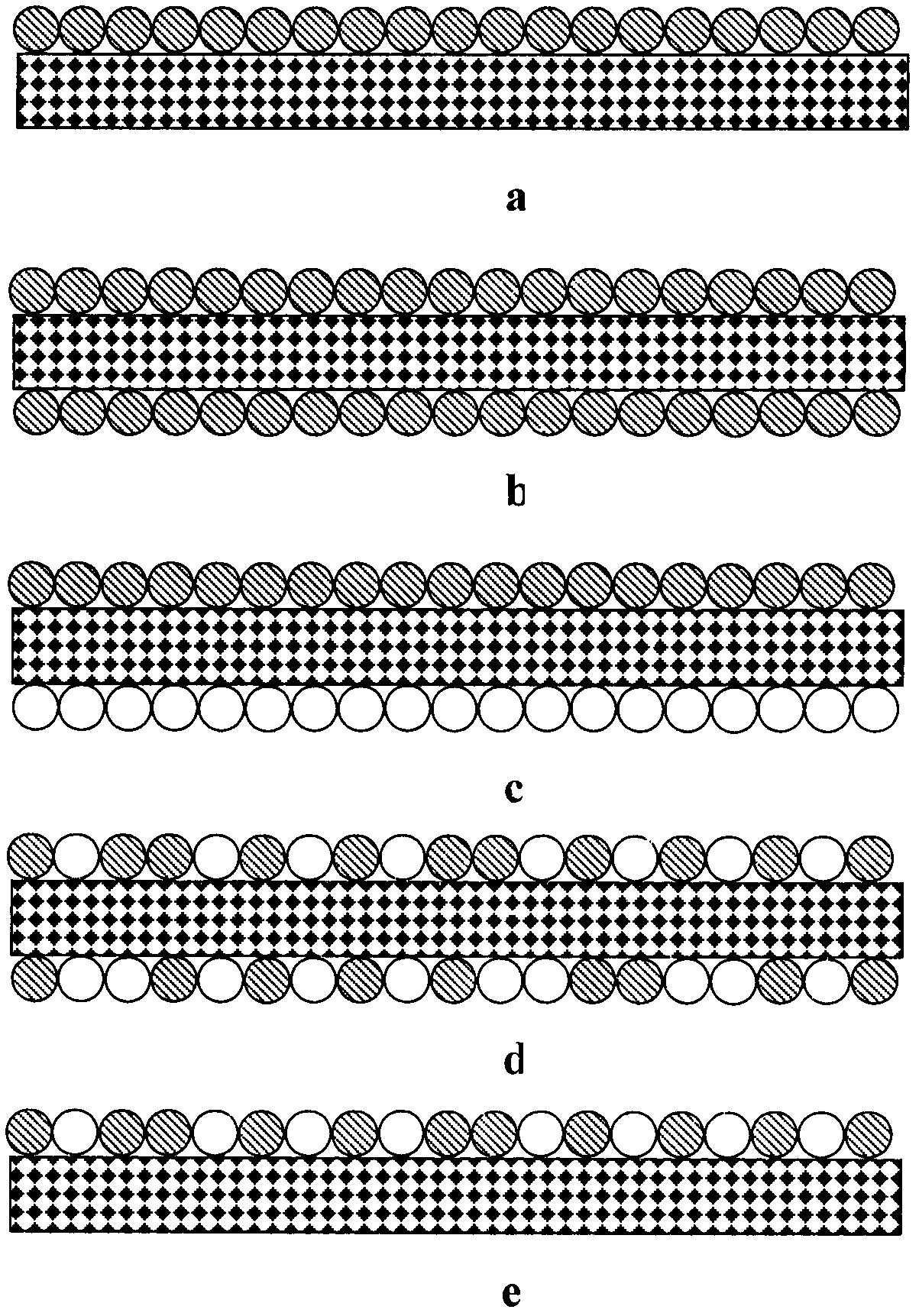

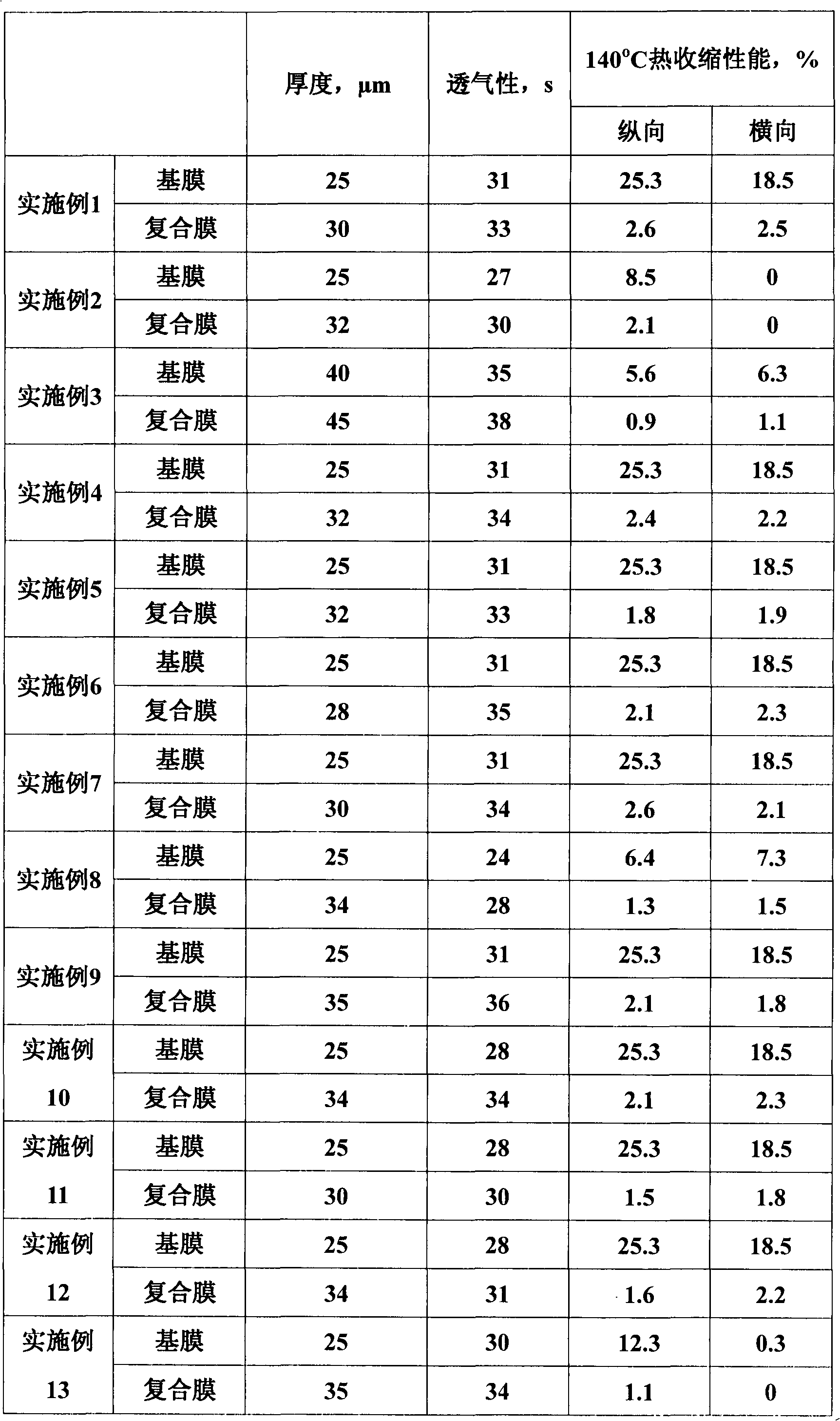

[0063] Vinylidene fluoride-hexafluoropropylene copolymer (Kynar2801) (20 parts by weight) was added to a mixed solvent (600 parts by weight) of N-methyl 2-pyrrolidone (NMP) and acetone (wherein NMP: acetone v / v = 7:3), the solution was obtained after fully dissolving under stirring conditions, and slowly added aluminum oxide (85 parts by weight, average particle size 0.5 μm) and gelatin (5 parts by weight) to the solution, under ultrasonic and strong shear Continue to stir under the conditions to form a stable suspension, which is the coating slurry. A polyethylene single-layer separator with a thickness of 25 μm (porosity 35%) prepared by a wet method is first immersed in NMP to fill the inside of the separator with NMP, and after removing excess NMP on the surface, scrape a layer of coating on one surface of the separator. Apply the slurry, and after drying, form an aluminum oxide coating with a thickness of 5 μm to obtain a composite diaphragm with a thickness of 30 μm coat...

Embodiment 2

[0065] Polyurethane (10 parts by weight) is added in ethyl acetate (500 parts by weight), fully dissolved under stirring to obtain a solution, and zirconium dioxide (50 parts by weight, average particle diameter 1.0 μm), polyethylene wax (40 parts by weight, average particle size 0.5 μm) and polyoxyethylene ether (3 parts by weight), continue to stir under ultrasonic and strong shear conditions to form a stable suspension that is the coating slurry. The polypropylene single-layer diaphragm (porosity 45%) with dry uniaxial stretching thickness of 25 μm is first immersed in acetone so that the interior of the diaphragm is filled with acetone, and after the solvent on the surface of the diaphragm is volatilized, transfer printing One layer of coating slurry is coated, and after drying, a composite coating with a thickness of 7 μm is formed to obtain a composite diaphragm with a thickness of 32 μm coated on one side (the cross-sectional schematic diagram is as follows: figure 1 e ...

Embodiment 3

[0067] Add silicon dioxide (70 parts by weight, average particle diameter 2 μm), sodium polyacrylate (3 parts by weight) and gelatin (7 parts by weight) to polyurethane aqueous dispersion (20 parts by weight (solid content 30%)), add appropriate amount After adding water, stir under ultrasonic and strong shear conditions to form a stable suspension, which is the coating slurry. The double-sided dip-coating of the surface of a 40 μm thick polypropylene single-layer separator (porosity 42%) with a dry biaxially stretched thickness is formed after drying to a silicon dioxide coating with a thickness of 5 μm, and the thickness of the double-sided coating is 50μm composite diaphragm (the schematic diagram of its cross-section is shown in figure 1 shown in b). The air permeability and thermal shrinkage performance at 140° C. of the tested composite film are listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com