Method for rapidly cutting silicon wafers with electroplating diamond wire with ultrahigh efficiency

A fast cutting and ultra-efficient technology, used in fine work equipment, work accessories, stone processing equipment, etc., can solve the problems of low efficiency of electroplating diamond wire cutting silicon wafers, and achieve the goal of reducing the demand for new lines and reducing fatigue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

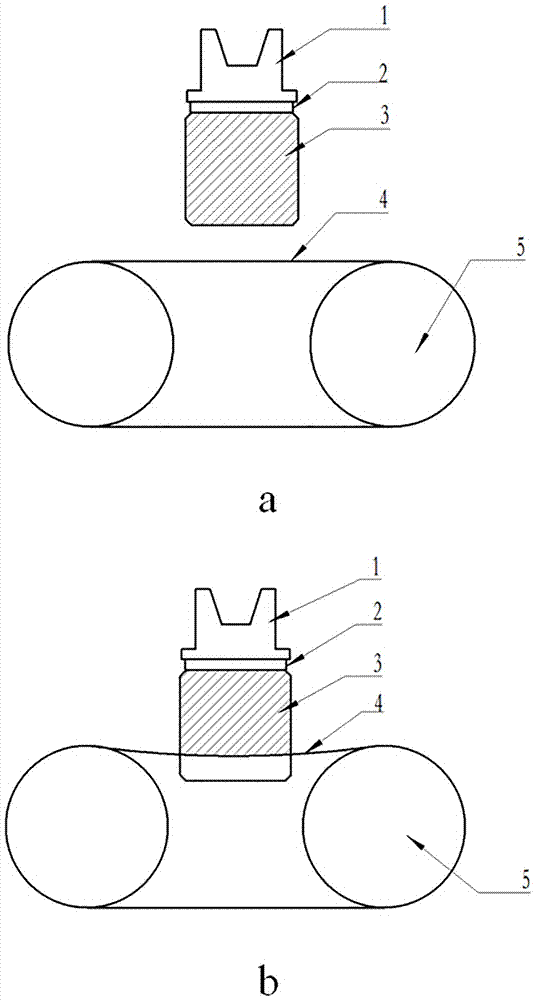

[0057] A method for quickly cutting silicon wafers with an ultra-efficient electroplating diamond wire, comprising the following steps: (1) sticking sticks, (2) loading, (3) preparing cutting fluid, (4) cutting, (5) unloading, (6) ) degumming, cleaning, (7) detection, packaging;

[0058] Bond the dovetail 1 and the resin plate 2, the resin plate 2 and the silicon rod 3 with epoxy resin AB glue; put the bonded whole on the loading and unloading tool through the dovetail, and send it to the slicer; cut the purchased high-tech Liquid, Defeng defoamer, and water are mixed evenly according to the mass ratio of 1:1:300, then poured into the cutting fluid tank and set aside.

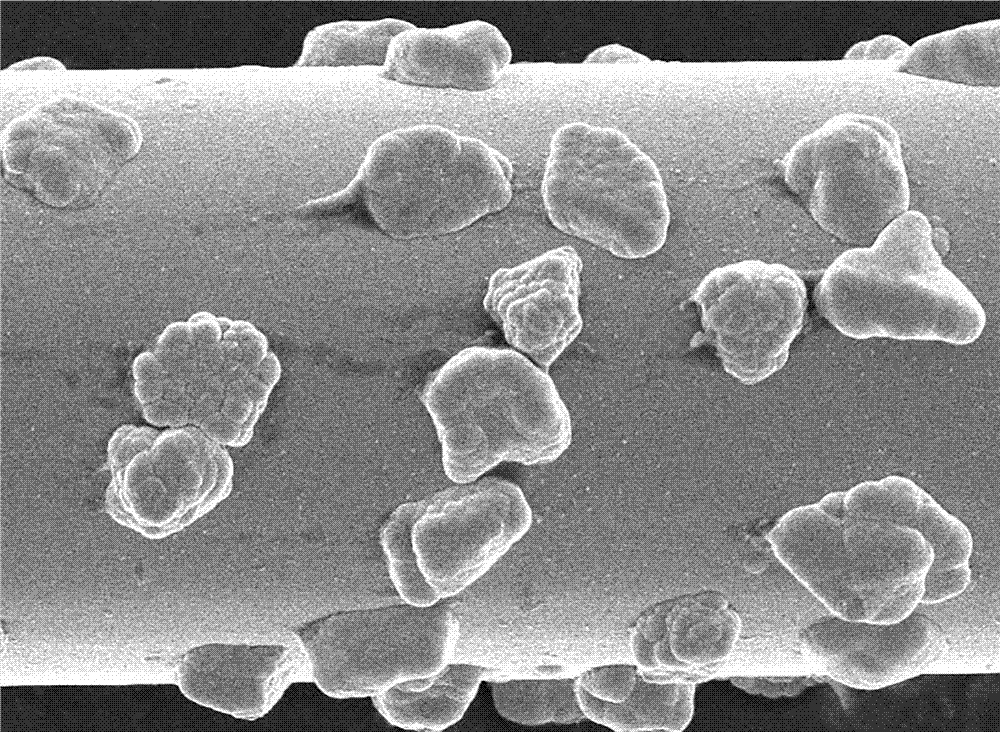

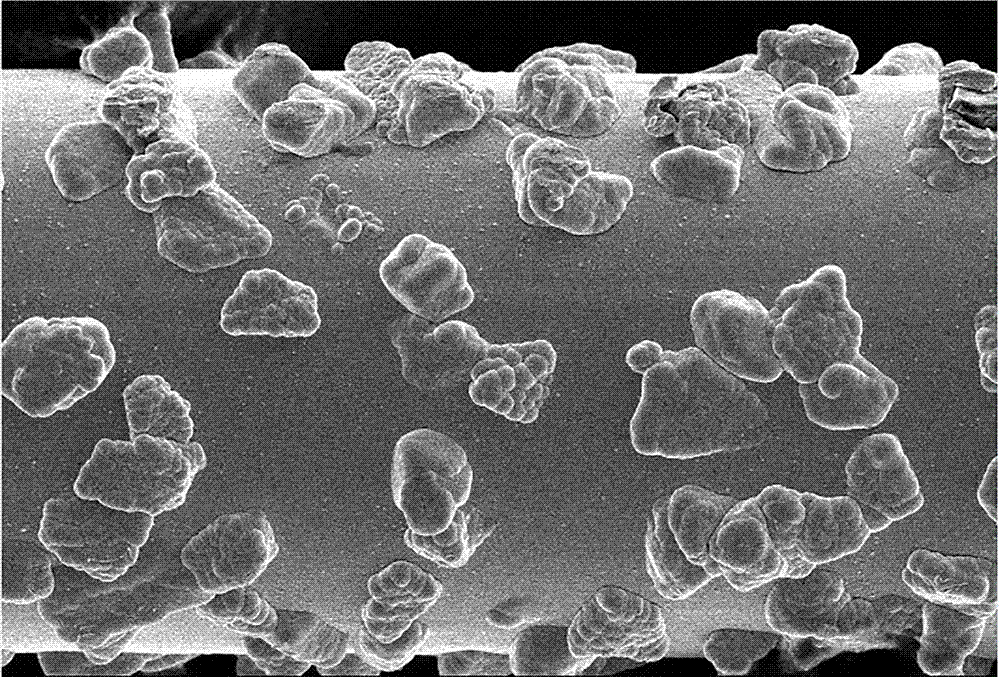

[0059] image 3 For the electron micrograph of the electroplated diamond wire used in the present embodiment, the electroplated diamond wire with a diameter of 70um is used as the cutting wire in the present embodiment, as shown in image 3 As shown, the density of diamond particles on the electroplated diamo...

Embodiment 3

[0070] A method for quickly cutting silicon wafers with an ultra-efficient electroplating diamond wire, comprising the following steps: (1) sticking sticks, (2) loading, (3) preparing cutting fluid, (4) cutting, (5) unloading, (6) ) degumming, cleaning, (7) detection, packaging;

[0071] Bond the dovetail 1 and the resin plate 2, the resin plate 2 and the silicon rod 3 with epoxy resin AB glue; put the bonded whole on the loading and unloading tool through the dovetail, and send it to the slicer; cut the purchased high-tech Liquid, Defeng defoamer, and water are mixed evenly according to the mass ratio of 1:1:300, then poured into the cutting fluid tank and set aside.

[0072] Such as image 3 Shown is the electron micrograph of the electroplated diamond wire used in the present embodiment, adopting the electroplated diamond wire with a diameter of 70um as the cutting wire in the present embodiment, as image 3 As shown, the density of diamond particles on the electroplated di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com