Sericite/TiO2 composite material with white pigment property

A composite material and sericite technology, which is applied in the field of preparation of sericite/TiO2 composite materials, can solve the problems of composite pigments such as poor performance, instability, lack of exciting external force and bonding groups, and achieve low price and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

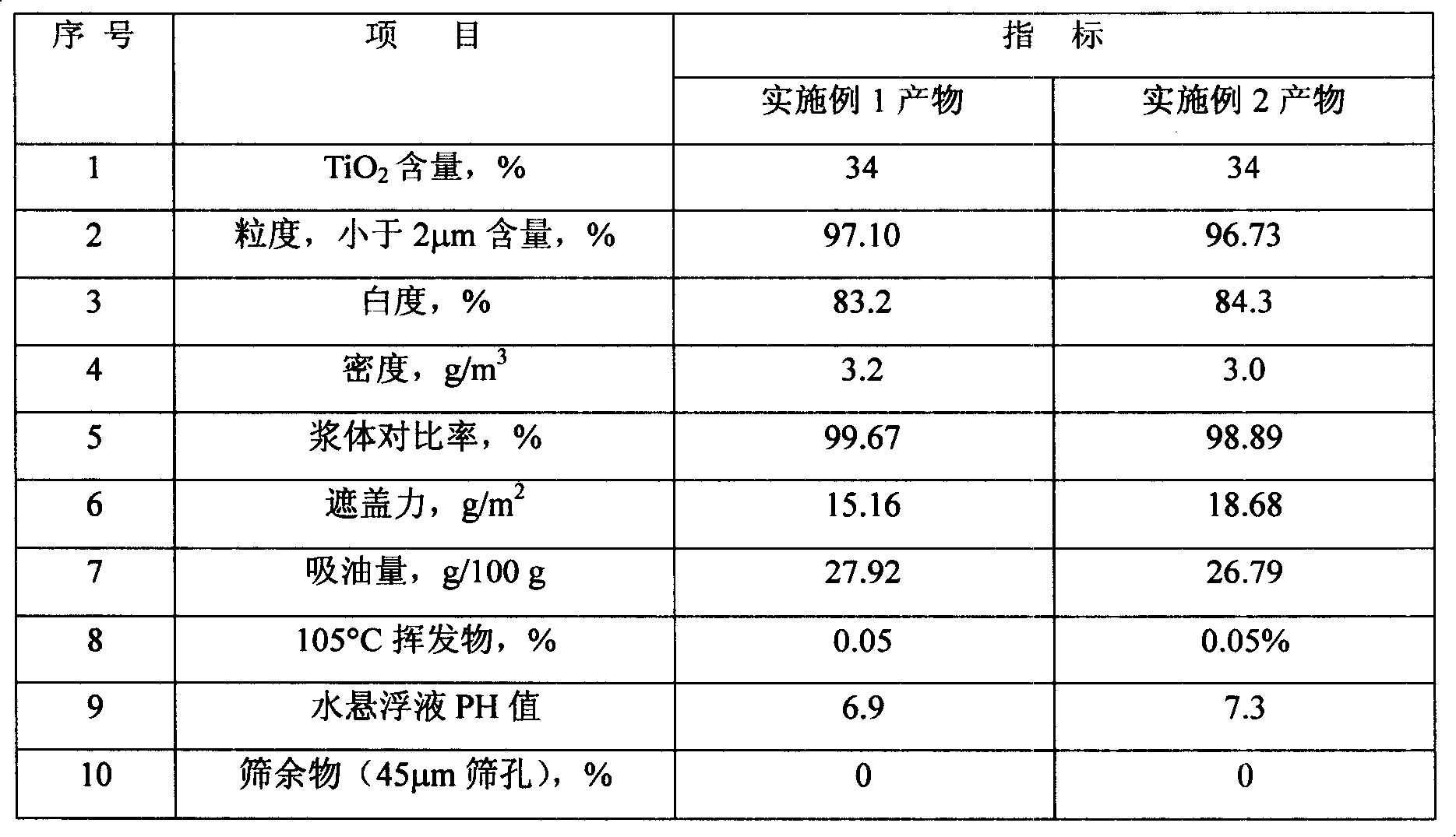

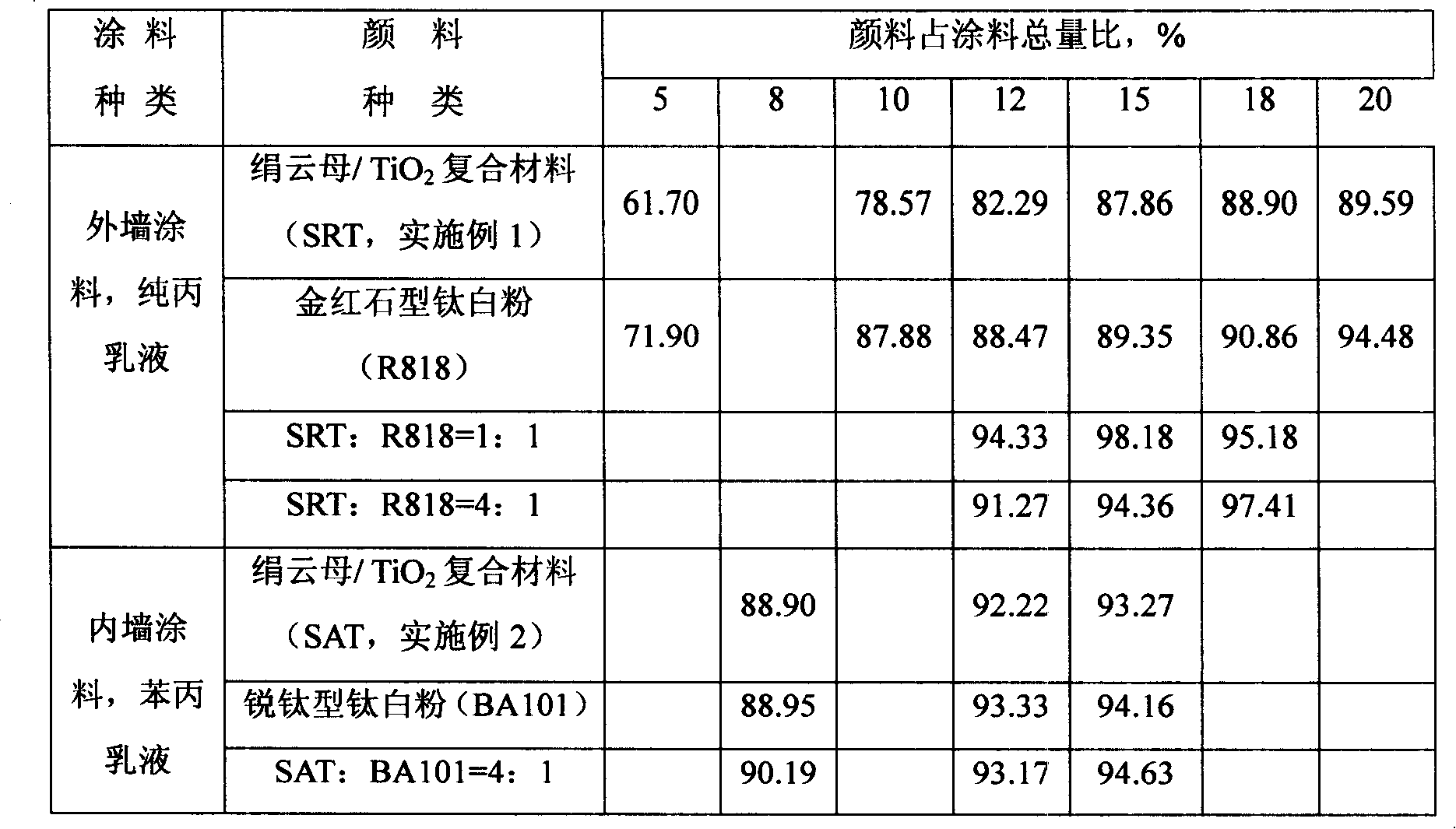

Embodiment 1

[0030] 1. 400kg of sericite powder (500 orders) and 400kg of deionized water are placed in the ultra-fine grinding system of the wet stirring mill, stirred for 15min by a stirrer with high-speed stirring, and then added a solution containing 4kg of sodium tripolyphosphate ( Solution concentration 20%, add this solution 20kg), then stir for 40min to make ultrafine grinding slurry;

[0031] 2. Start the ultra-fine grinding system of the wet stirring mill, and grind the slurry made of sericite powder and water according to the continuous grinding method to make the particle size of the ground product reach less than 2 μm and the content is 70%;

[0032] 3. The crystallized TiO 2 (rutile titanium dioxide) 200kg, deionized water 200kg placed in a stirring tank with high-speed stirring effect and stirred for 15min, then added a solution containing 3kg sodium tripolyphosphate (solution concentration 20%, add 15kg of this solution), and stirred for 40min make a paste;

[0033] 4. Gr...

Embodiment 2

[0040] 1. 400kg of sericite powder (500 orders) and 400kg of deionized water are placed in the ultra-fine grinding system of the wet stirring mill, stirred for 15min by a stirrer with high-speed stirring, and then added a solution containing 4kg of sodium tripolyphosphate ( Solution concentration 20%, add this solution 20kg), then stir for 40min to make ultrafine grinding slurry;

[0041] 2. Start the ultra-fine grinding system of the wet stirring mill, and grind the slurry made of sericite powder and water according to the continuous grinding method to make the particle size of the ground product reach less than 2 μm and the content is 70%;

[0042] 3. The crystallized TiO 2 (Anatase Titanium Dioxide) 200kg, 200kg of deionized water are placed in a stirring tank with high-speed stirring and stirred for 15min, then add a solution containing 3kg of sodium tripolyphosphate (solution concentration 20%, add 15kg of this solution), and stir 40min to make slurry;

[0043] 4. Grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com