Radiation crosslinking flame-retardant polyolefin heat-shrinkable material and preparation method thereof

A radiation cross-linked, polyolefin substrate technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problem of radiation cross-linked flame retardant polyolefin heat shrinkable materials failing to pass the thermal shock test, and achieve low prices. , the effect of easy purchase of raw materials and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

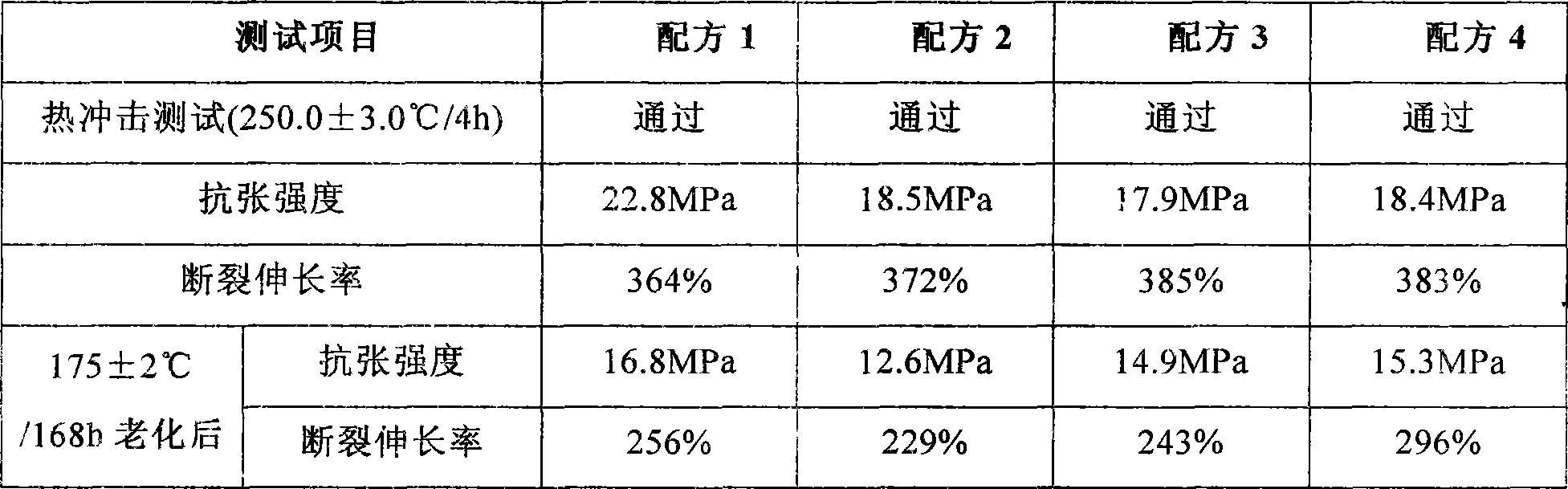

Examples

Embodiment Construction

[0021] The present invention proposes a radiation-crosslinked flame-retardant polyolefin heat-shrinkable material, which is composed of substances in the following weight ratios:

[0022] 100 parts of polyolefin substrate;

[0023] Composite flame retardant 0-100 parts;

[0024] 1 to 3 parts of lubricant;

[0025] Color masterbatch 0~5 parts;

[0026] Composite antioxidant 1-5 parts;

[0027] Titanium dioxide 0-2 parts.

[0028] The polyolefin base material is a combination of one or more of the following substances: ethylene-vinyl acetate copolymer EVA, polyethylene, ethylene-propylene-diene rubber, and ethylene-octene copolymer.

[0029] The melt index MI of the above-mentioned ethylene-vinyl acetate copolymer is 1-6 g / 10 min, and the vinyl acetate content VA% is 14-40%. The polyethylene melt index MI is 1-10 g / 10 min. The above-mentioned EPDM rubber has a Mooney viscosity (ML1+4, 105°C) of 30-70, an ethylene content of 50-70%, a propylene content of 30-50%, and an ENB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com