Multistage turbocompressor

A technology of turbo compressors and compressors, which is applied to mechanical equipment, gear transmissions, machines/engines, etc., to achieve the effects of low cost, reduced volume, and expanded space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

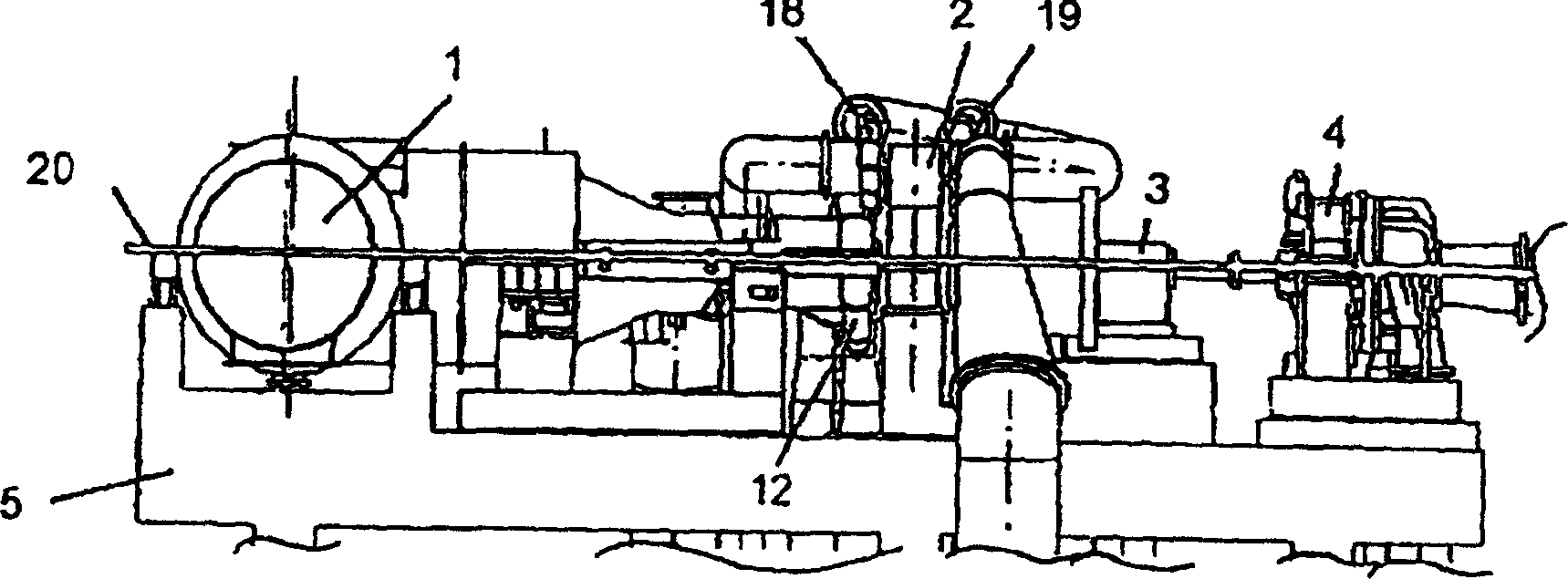

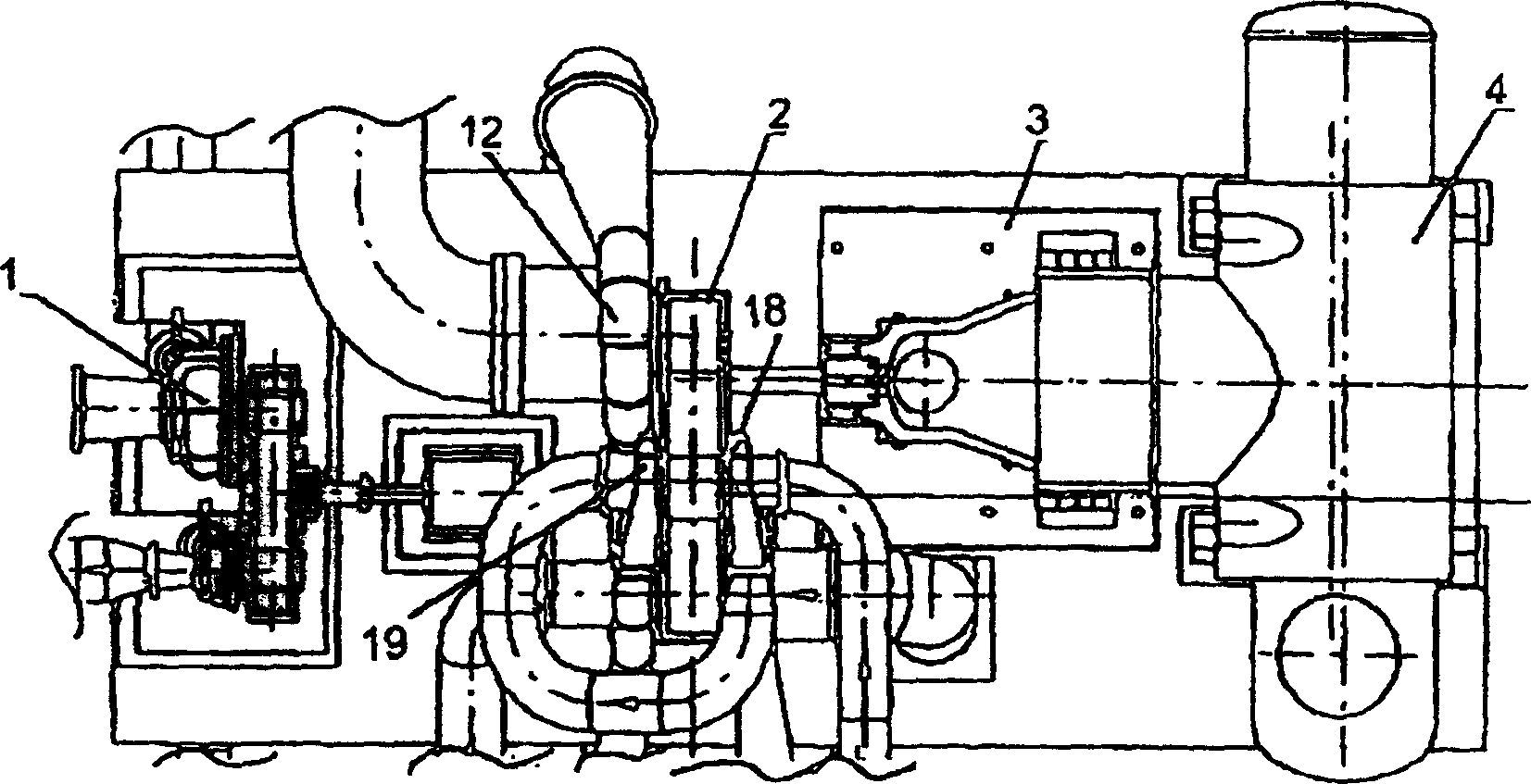

[0010] figure 1 The machine drive line shown is part of a chemical plant for the treatment and further processing of gases. This machine transmission line is made up of power unit 1 and transmission compressor 2. According to the type of chemical equipment, the machine transmission line may also include a motor / generator 3 and an expander 4 . Each unit is connected with each other and installed on a base that is on the concrete or steel foundation, that is, the machine platform 5 . Below the machine platform 5 are a plurality of coolers, a condenser and other units required for the operation of the equipment.

[0011] The power unit 1 is preferably formed as a steam turbine, the output shaft of which is connected to the drive shaft 6 of the downstream drive compressor 2 . The gear compressor 2 is a multi-stage turbo compressor with an integrated gear and is used for compressing gas.

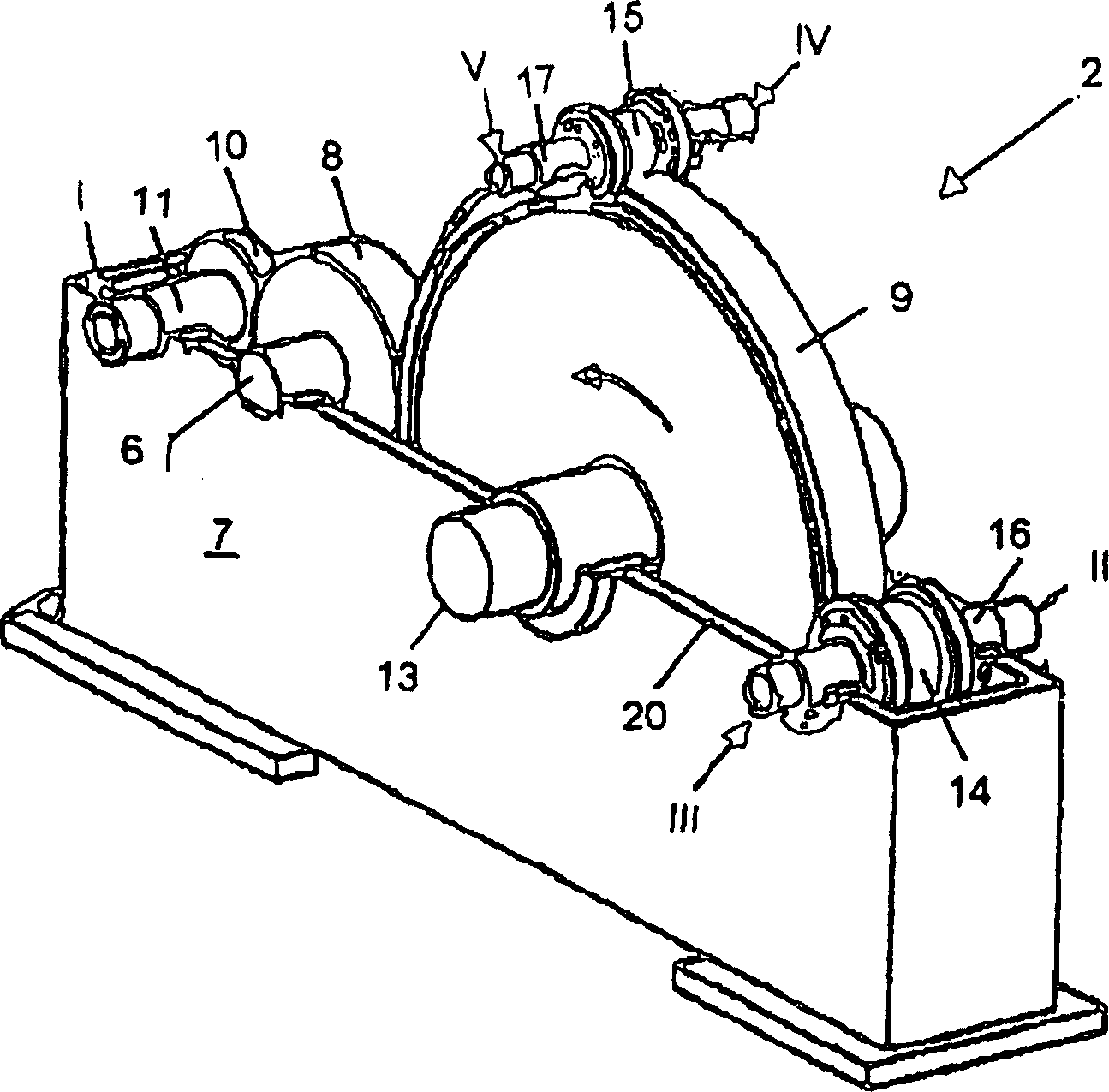

[0012] according to image 3 The drive compressor 2 comprises a housing 7 in which a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com