Model prediction control method and model prediction control system for all working conditions of wind generating set

A wind turbine, model predictive control technology, applied to the control of wind turbines, wind turbines, control system types, etc., can solve problems such as overshoot, inability to guarantee stable operation, fast follow-up, oscillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0161] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

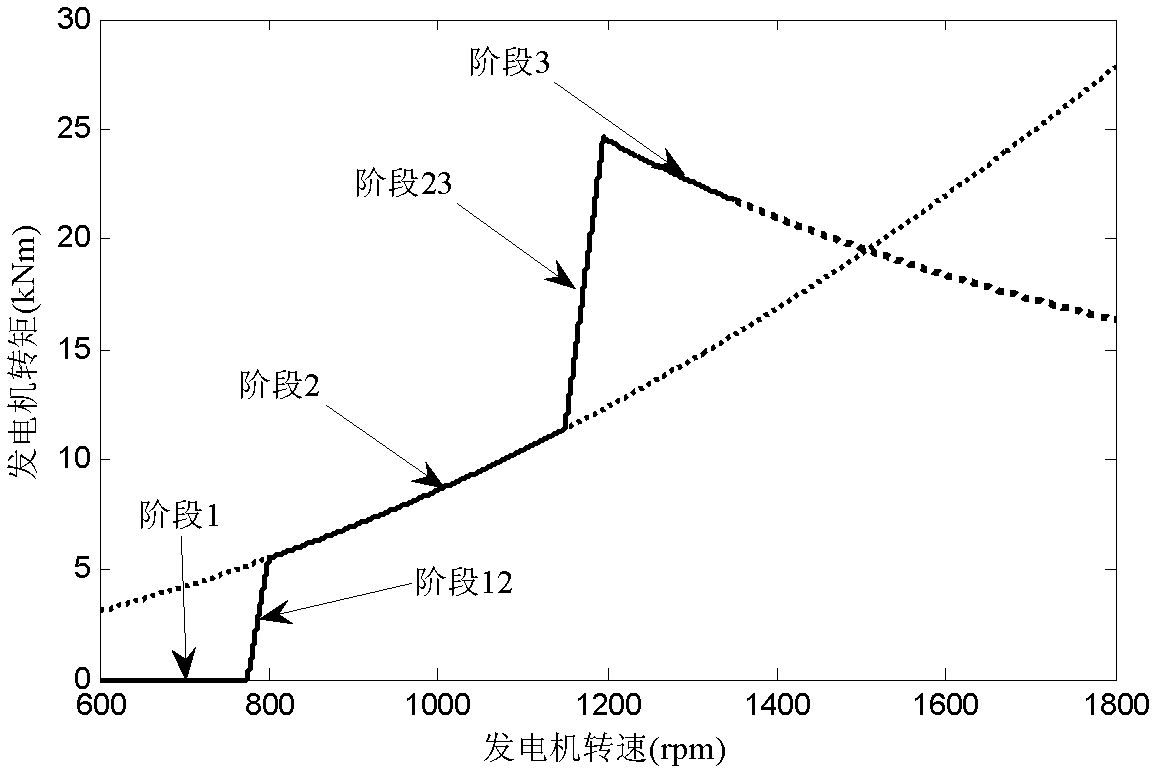

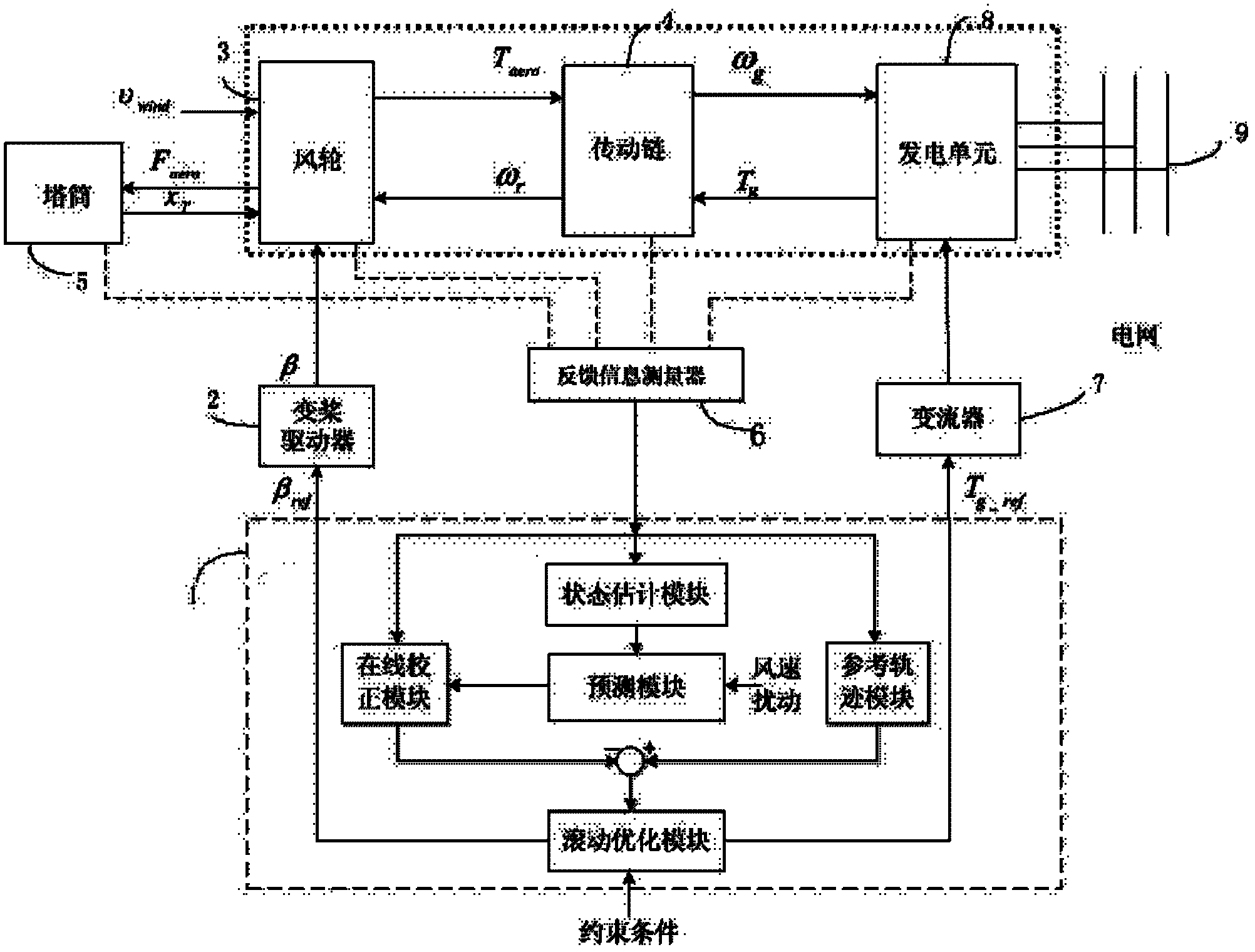

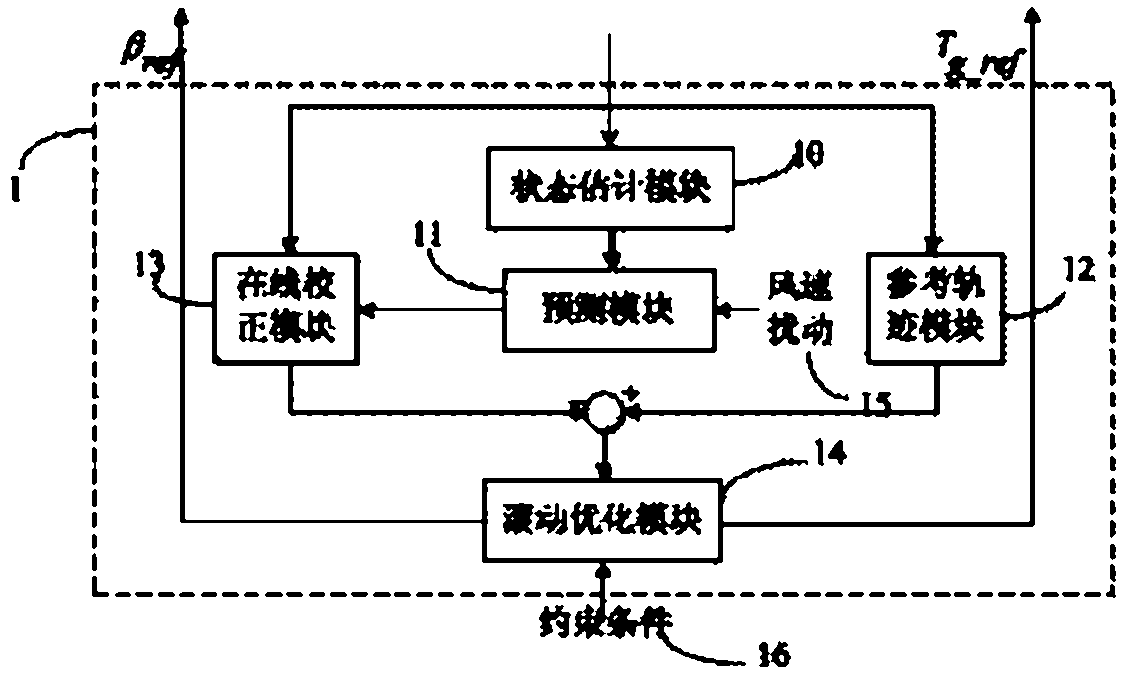

[0162] This embodiment adopts the full working condition model predictive control system of 3MW doubly-fed wind power generating set, including MPC controller 1, feedback information measuring device 6, wind wheel 3, transmission chain 4, tower tube 5, power generation unit 8, pitch changer Drive 2, converter 7, control principle such as figure 2 As shown, the output terminal of the power generation unit is connected to the power grid, and the pitch driver equipped with the wind rotor of the power generation unit adjusts the pitch angle of the blades to achieve the maximum utilization of wind energy; the input terminal of the pitch driver is connected to the output port of the MPC controller, and the converter The input end is connected to the output port of the MPC controller, and the output end of the converter is connected to the power generation un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com