Special soilless organic composite matrix for raising seedlings of mechanically-transplanted japonica rice and preparation method of matrix

A composite substrate, japonica rice technology, applied in the application, fertilizer mixture, fertilization device and other directions, can solve the problems of not taking into account the growth characteristics and fertilizer requirements of different types of rice, the difficulty of degrading auxiliary materials, and the unfavorable root growth of seedlings. The effect of increasing water retention and ventilation performance, reducing fertilizer application, and strong adaptability to sowing date

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

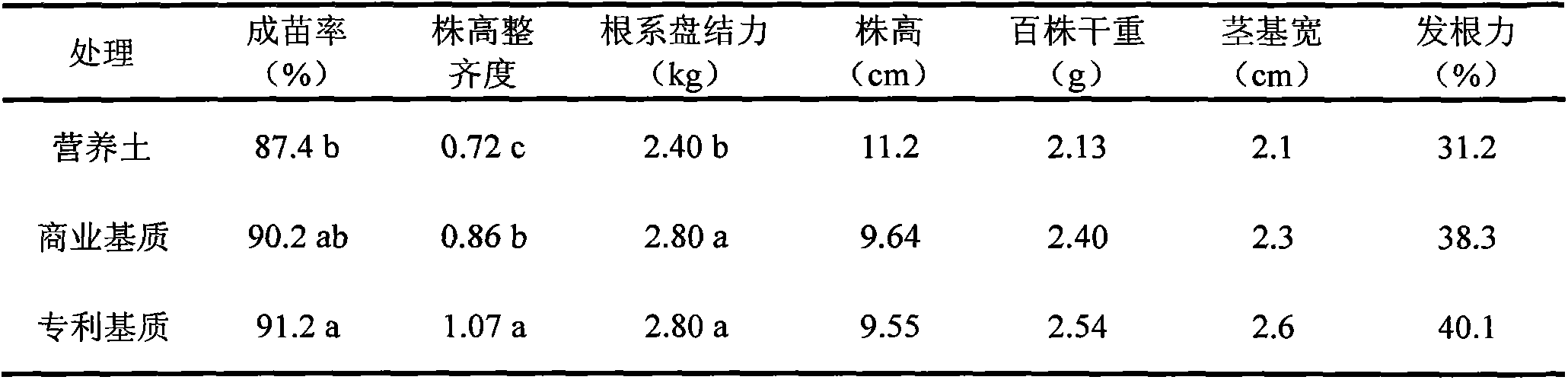

Image

Examples

Embodiment 1

[0021] Take 55kg of rice straw, process the straw into 0.2-2m long sections with a pulverizer or a guillotine knife; collect 35kg of cow dung, dry it, and crush the large pieces into powder. The above-mentioned agricultural waste and 10 kg of sun-dried rice husks were evenly mixed, and 2 kg of urea and 15 grams of straw decomposing agent were added. Mix the above-mentioned mixed materials, adjust the water content to 65% (cluster into a ball by hand, squeeze out the water), and then stack. Then cover the surface with a sack or a layer of film to keep it moist and start fermentation. After 7-10 days, the pile temperature rises above 60°C, and the pile is turned once, and then the pile is turned 7 times according to the pile temperature, and then the fermentation is in place. Air-dry the fermented main raw materials naturally and crush them to 1-4 mm, add 15 kg of peat, 0.5 kg of urea, 0.6 kg of potassium dihydrogen phosphate, 0.6 kg of phosphate fertilizer (phosphorus pentoxid...

Embodiment 2

[0023] Take 65kg of rice straw, process the straw into 0.2-2m long sections with a pulverizer or a guillotine; collect 30kg of cow dung, dry it, and crush the large pieces into powder. The above-mentioned agricultural waste and 5 kg of sun-dried rice husks are evenly mixed, and 3 kg of urea and 20 grams of straw decomposing agent are added. Mix the above-mentioned mixed materials, adjust the water content to 65% (cluster into a ball by hand, squeeze out the water), and then stack. Then cover the surface with a sack or a layer of film to keep it moist and start fermentation. After 7-10 days, the pile temperature rises above 60°C, and the pile is turned once, and then the pile is turned 7 times according to the pile temperature, and then the fermentation is in place. Air-dry the fermented main raw materials naturally and crush them to 1-4mm, add 15 kg of peat, 1 kg of 15:15:15 compound fertilizer, 0.6 kg of phosphate fertilizer (phosphorus pentoxide), or 6 grams of paclobutrazo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com