Furnace cooling intensity control method based on vague PID control

A technology of cooling intensity and control method, used in cooling devices, adaptive control, general control systems, etc., can solve problems such as poor stability, inability to achieve precise control, and narrow application range, and improve accuracy and stability. , reduce manpower consumption, realize the effect of real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

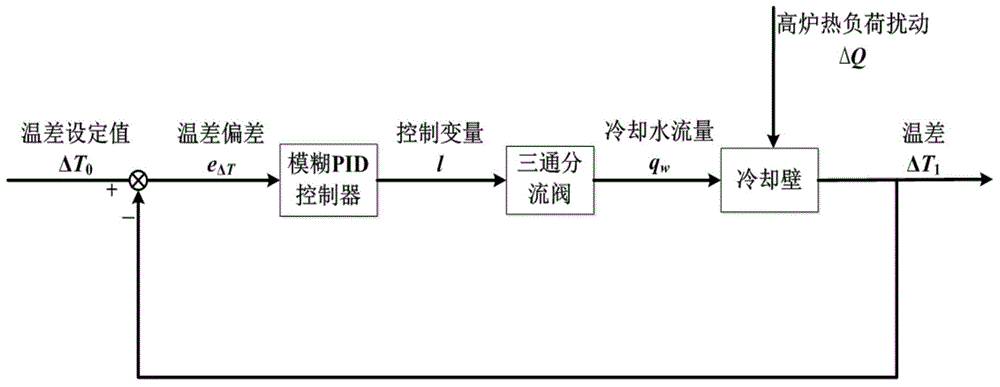

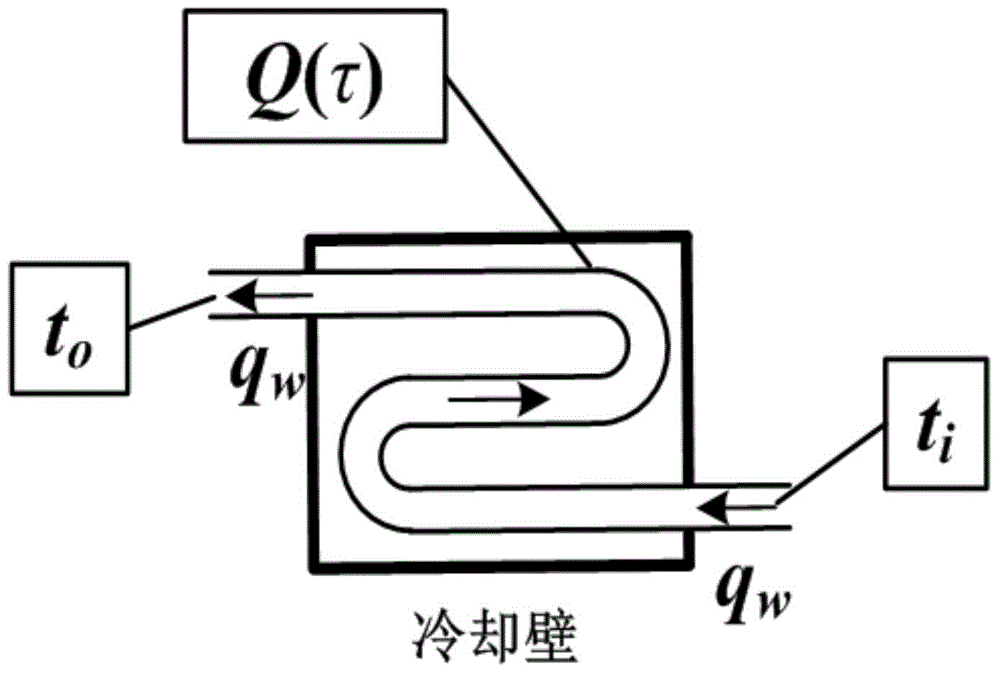

[0037] In conjunction with the accompanying drawings, a blast furnace cooling intensity control method based on fuzzy PID control in this embodiment aims to control the blast furnace cooling intensity by adjusting the cooling water flow rate, maintain a constant temperature difference of the blast furnace cooling water, and maintain a balance between the cooling intensity and the blast furnace heat load. The balance between them can achieve the longevity of the blast furnace.

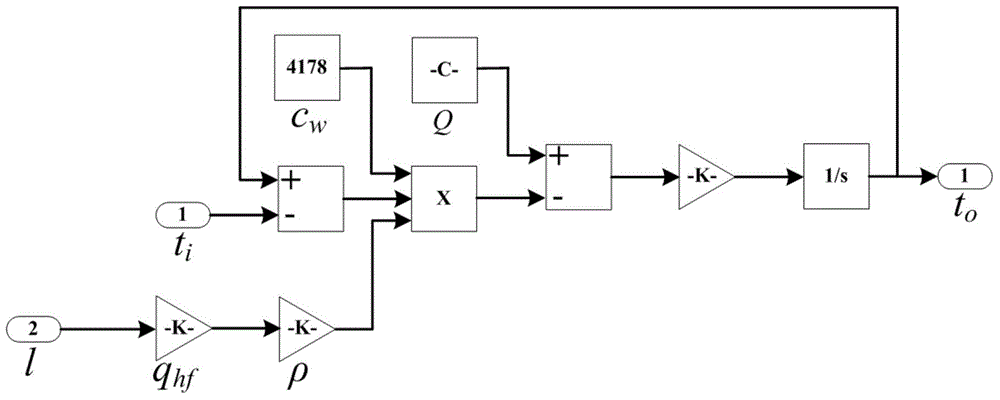

[0038] The heat balance equation of the stave is:

[0039] Q=Q 1 +Q 2 (1)

[0040] Q 1 =c w m f (t o -t i ) = c w vSρ(t o -t i ) = c w q w ρ(t o -t i ) (2)

[0041] In the formula, Q is the total heat transfer from the blast furnace to the stave; Q 1 is the heat taken away from the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com