Electro hydraulic servo system self-correction fuzzy PID control method

An electro-hydraulic servo system and self-correction technology, applied in the field of control algorithms of electro-hydraulic servo systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention and its implementation will be further described in detail below in conjunction with the accompanying drawings.

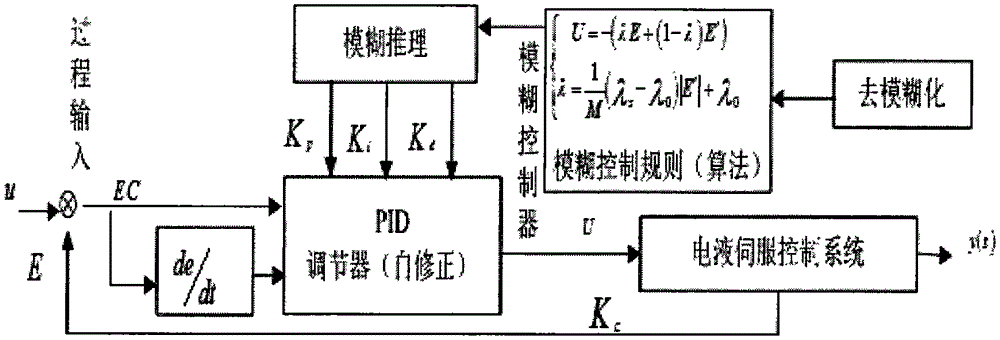

[0029] Such as figure 1 As shown, a method for self-correcting fuzzy PID control of an electro-hydraulic servo system comprises the following steps:

[0030] Step 1. Determine the input and output of the self-correcting fuzzy PID controller

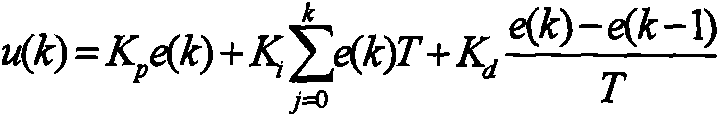

[0031] Taking the electro-hydraulic servo control mechanism as the controlled object, taking the error E between the feedback value of the controlled object and the target value and the error change rate EC as the input of the fuzzy PID controller, the parameter variation △k of the fuzzy PID controller p , Δk i and Δk d as output;

[0032] Step 2. Select input quantity, output quantity membership degree and its domain of discussion

[0033] Input deviation e and deviation change rate ec, and output △k p , Δk i and Δk d The domain of variable fuzzy set is [-M, M], and its membership function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com