Test system and control method for electro-hydraulic servo online self-adjusting fuzzy PID control

An electro-hydraulic servo system and electro-hydraulic servo technology are applied in the direction of electric controllers and controllers with specific characteristics, which can solve the problems of difficult to meet the control requirements of the electro-hydraulic servo system, poor system identification, and complex structure of the test system. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

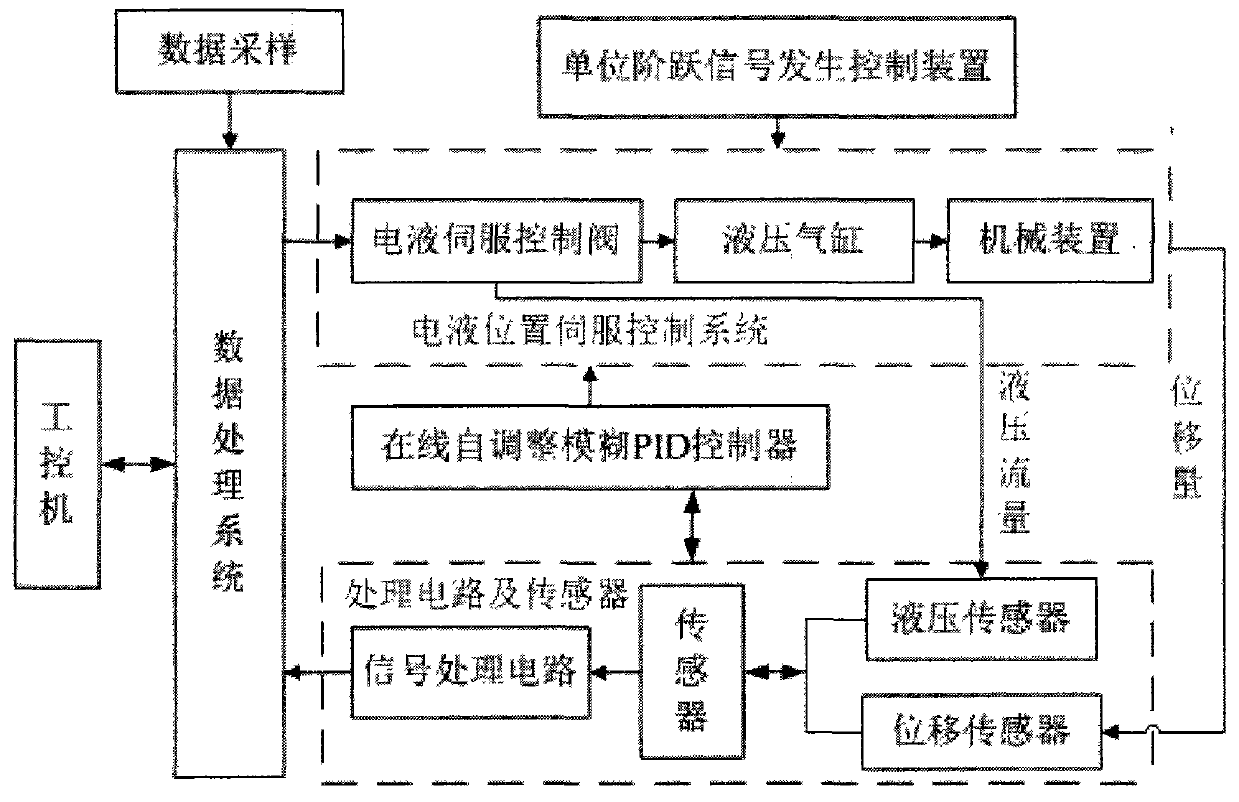

[0047] This embodiment provides a test system for electro-hydraulic servo on-line self-adjusting fuzzy PID control, its structural diagram is as follows figure 1As shown, it includes industrial computer, data processing system, electro-hydraulic servo control system, online self-adjusting fuzzy PID controller, processing circuit and sensor; The electro-hydraulic servo system performs online self-adjusting fuzzy PID control to realize the test control of the electro-hydraulic servo system.

[0048] The data processing system is used in a USB2832 data acquisition card, and can be plugged and played to realize digital quantity conversion.

[0049] The processing circuit and the sensor include the processing circuit and the sensor; the sensor includes a hydraulic sensor and a displacement sensor, which respectively convert the hydraulic signal into a current and the displacement signal into a voltage signal.

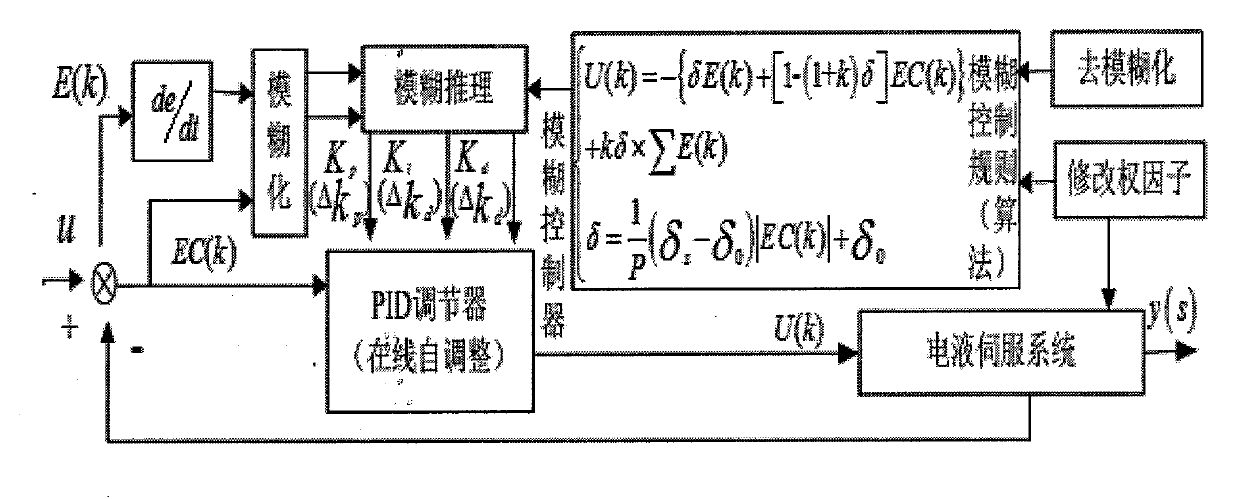

[0050] The online self-adjusting fuzzy PID controller is mainly used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com