Automatic testing system for battery equalization module packing

A balanced module, automatic detection technology, applied in battery circuit devices, measurement of electricity, electrical components, etc., can solve problems such as time-consuming and labor costs, difficulty in counting module test results, and single battery bias, and achieve detection time. Shorten, improve the quality of the factory, the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

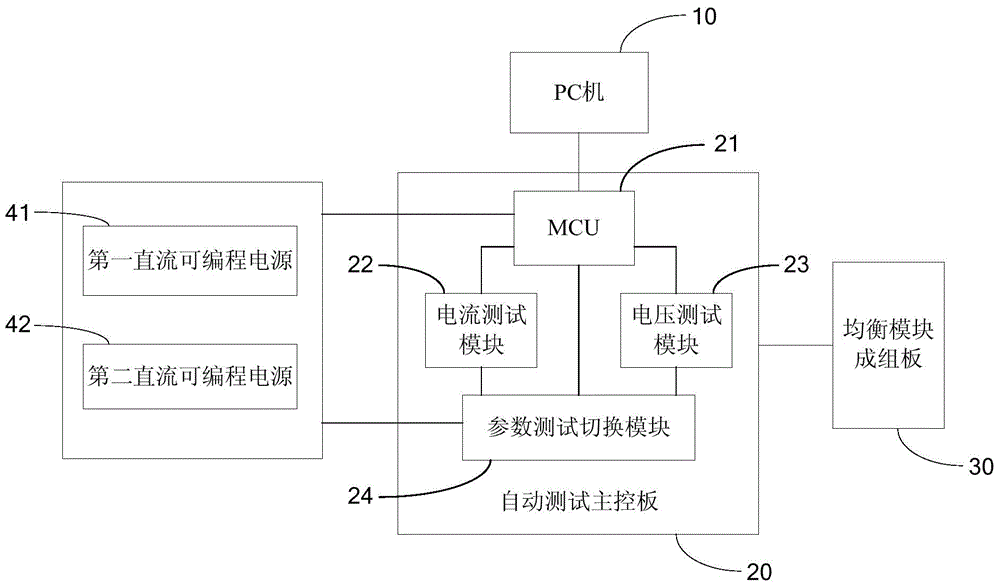

[0021] Please refer to figure 1 , is a schematic diagram of the module structure of a battery balancing module group automatic detection system according to an embodiment of the present invention, including: a PC 10, an automatic test main control board 20, two DC programmable power supplies (including the first DC programmable power supply 41 and the second DC programmable power supply 42) and a test stand for placing the balancing module group board 30.

[0022] The PC 10 is a computer equipped with automatic testing host computer software, the PC 10 is connected with the MCU 21 of the automatic testing main control board 20, and the whole battery balancing module can be controlled by the PC 10 to form a group automatic detection system The detection process, and display the detection process and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com