High-efficient detection system for injection molding product quality

A detection system and injection molding product technology, applied in sorting and other directions, can solve problems such as affecting the sales effect and use effect of injection molding products, reducing the yield of injection molding products, etc., to achieve efficient detection, improve factory quality and yield, and avoid lag Sexuality and Inefficiency Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

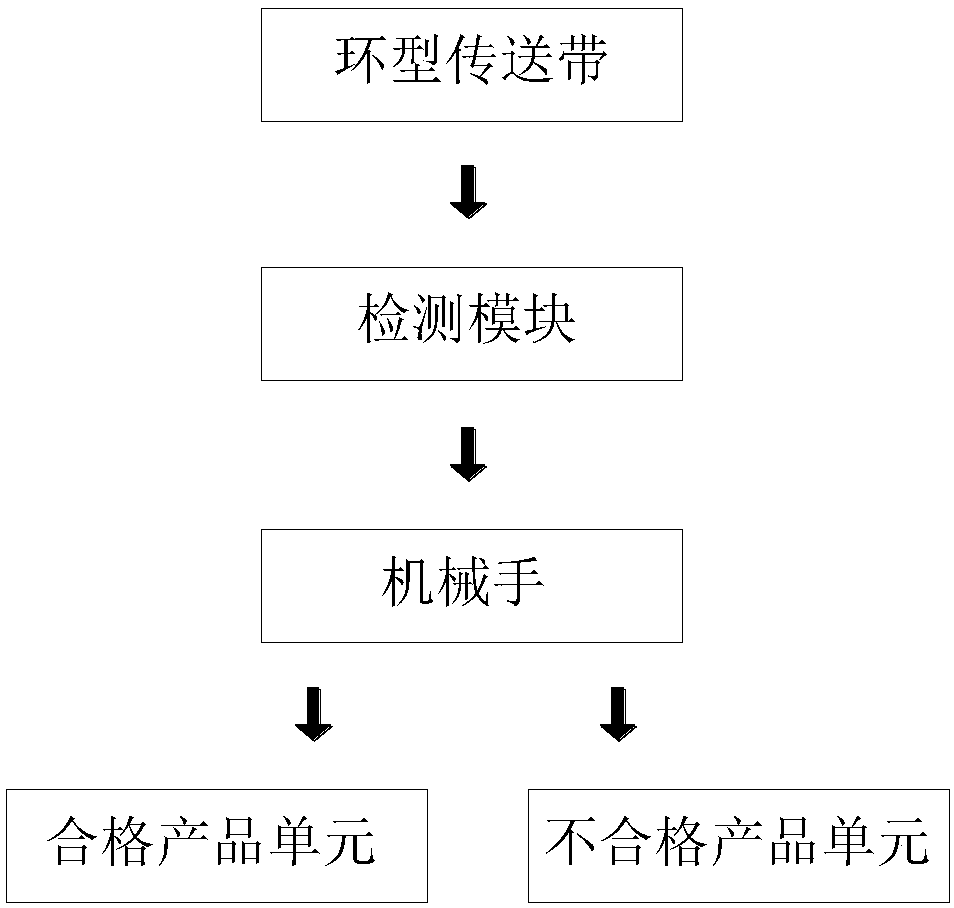

[0026] Such as figure 1 as shown, figure 1 It is a high-efficiency inspection system for the quality of injection molding products proposed by the present invention.

[0027] refer to figure 1 , the high-efficiency detection system for injection molding product quality proposed by the present invention includes: an endless conveyor belt, a detection module, a manipulator, a qualified product unit, and an unqualified product unit;

[0028] There are n stations evenly arranged on the endless conveyor belt; using the endless conveyor belt to transport the injection products, on the one hand, prolongs the residence time of the products on the conveyor belt, and provides sufficient time for the detection module to collect the image information of the injection molding products. It is beneficial to ensure the comprehensiveness of image information collection. On the other hand, the endless conveyor belt provides the opportunity for the detection module to collect all-round image i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com