Pipe fitting unloading device and unloading method for malleable cast iron pipe fitting end facing machine

A technology of unloading device and flat head machine, which is applied in metal processing and other directions, can solve the problems of affecting processing efficiency, pipe blockage, and fast discharge speed, etc., and achieve the effect of improving the quality of the factory and improving the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

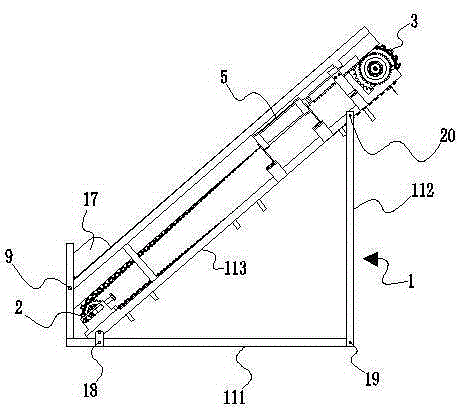

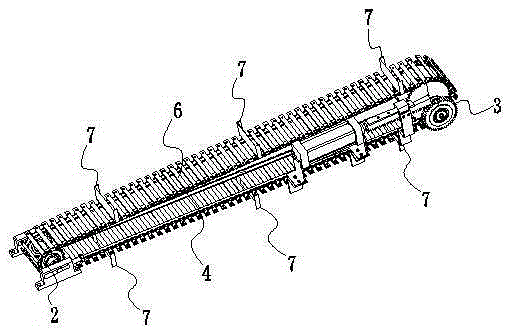

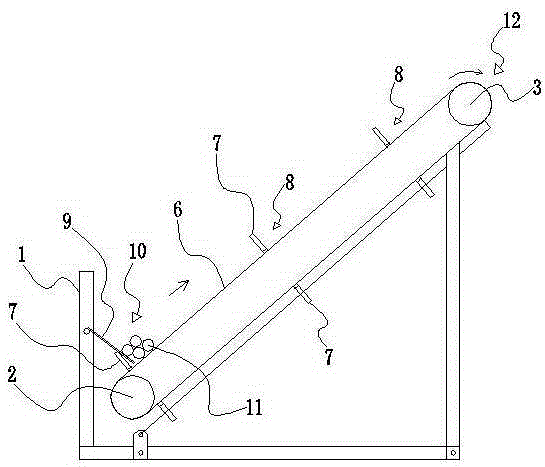

[0034] Example: such as Figure 1 to Figure 5 As shown, a kind of unloading device used for the flat head machine of malleable steel pipe fittings includes a frame 1 and a sprocket chain conveying part obliquely arranged on the frame 1, and the sprocket chain conveying part comprises a The driven double sprocket 2 and the driving double sprocket 3 on 1, the driven double sprocket 2 is located at the lower position, the driving double sprocket 3 is located at the upper position, and the driven double sprocket 2 and the driving double sprocket 3 pass through The double chains 4 are connected with transmission, and the frame 1 is provided with a driving device 5 for providing power to the active double sprockets 3, a chain plate 6 is arranged between the double chains 4, and a chain plate 6 is also arranged on the double chains 4. A plurality of lifting baffles 7 perpendicular to the chain plate 6, a plurality of lifting baffles 7 are successively distributed on the double chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com