Manufacturing method for solar energy battery, and solar energy battery

A technology for solar cells and manufacturing methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high manufacturing cost, difficulty in retaining passivation layer process complexity, and many process steps, so as to improve production efficiency and conversion efficiency. Improve and simplify the effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods that do not specify specific conditions in the following examples, select according to conventional methods and conditions, or according to the product instructions.

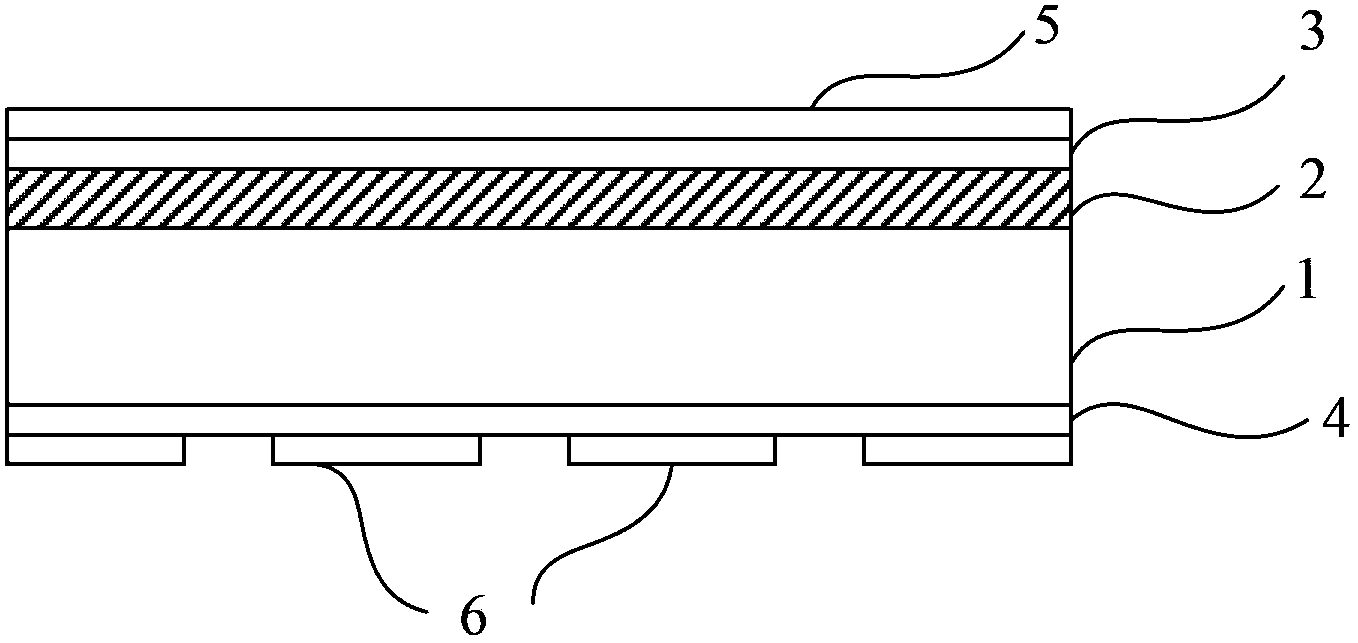

[0031] refer to Figure 1-4 , the manufacture method of this solar cell, comprises the following steps:

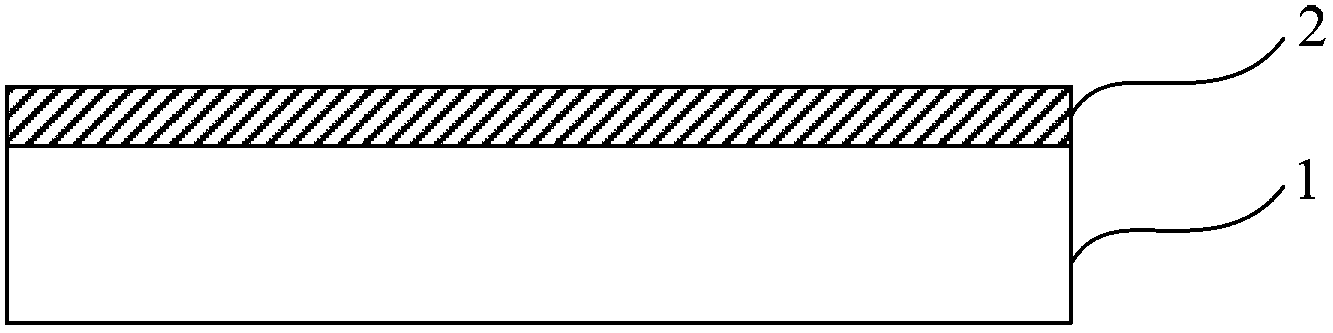

[0032] Step S 1 ,refer to figure 1 , provide a substrate 1, and texture the front surface of the substrate 1, and form a PN structure on the substrate 1 by means of ion implantation. For example, the PN structure is obtained by implanting ions of the second conductivity type on the front surface of the substrate 1 of the first conductivity type to form a doped layer 2 of the second conductivity type.

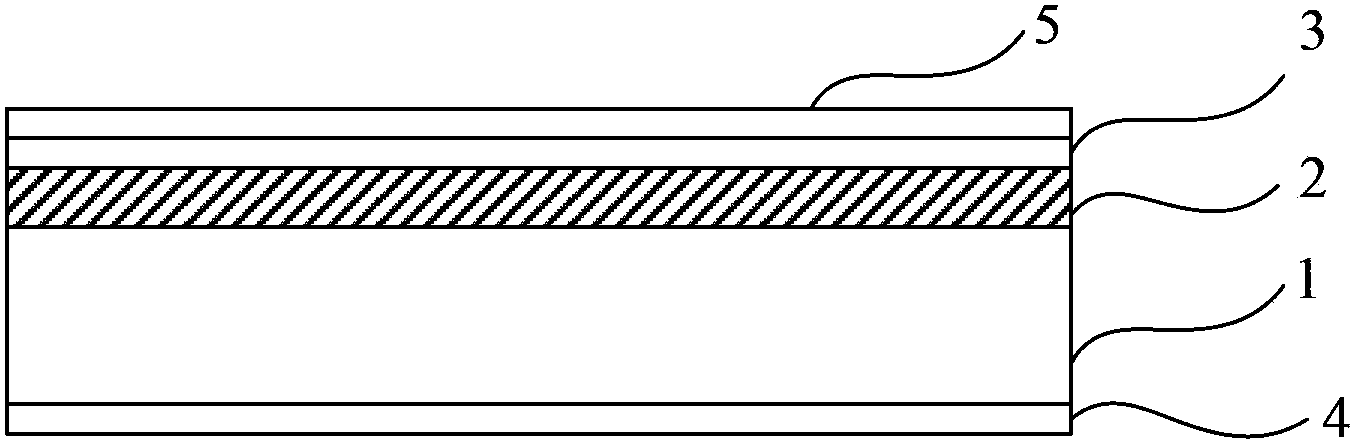

[0033] Step S 2 ,refer to figure 2 , the PN structure is annealed, and while annealing, oxygen gas is introduced to form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com