Solar silicon wafer automatic wafer separator based on cyclic distribution device and wafer separation method thereof

A technology for solar silicon wafers and slicing machines, which is applied to electrical components, conveyor objects, transportation and packaging, etc., can solve the problems of fragile and difficult separation of silicon wafers, and achieves reduction of fragmentation rate, efficient separation, and improvement of production efficiency. and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

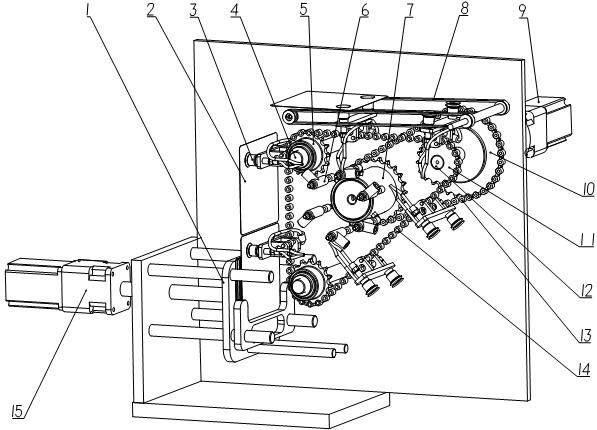

[0043] Such as figure 1 As shown, the present invention is based on the solar silicon chip automatic slicer of the circulation gas distribution device, comprising a feed system, a transmission system, and a circulation gas distribution device 7, and a circulation gas distribution device is arranged on one side of the feed system, and the circulation gas distribution device passes through The transmission system realizes the drive.

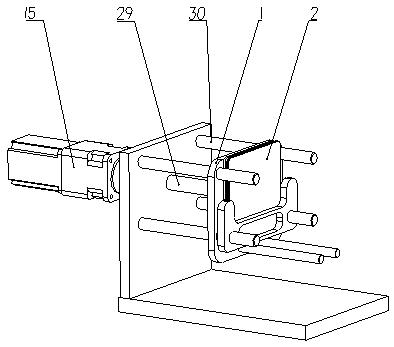

[0044] Such as figure 2 As shown, the feed system includes a feed box 1, a transmission rod 29, and a linear motor 15, the output shaft of the linear motor 15 is connected to one end of the transmission rod 29, and the other end of the transmission rod 29 is fixedly connected to the feed box 1; the linear motor 15 passes through the The vertical plate is supported and fixed, and a plurality of guide rods 30 are arranged between the vertical plate and the feed box 1;

[0045] There is a gap fit between the feed box 1 and the guide rod 30; a gap f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com