Blanking system for detecting and sorting silicon chip or cell

A cell and silicon wafer technology, applied in circuits, sorting, electrical components, etc., can solve the problems of low fragmentation rate, high fragmentation rate, inability to meet the sorting process of flexible batteries and high-efficiency batteries, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

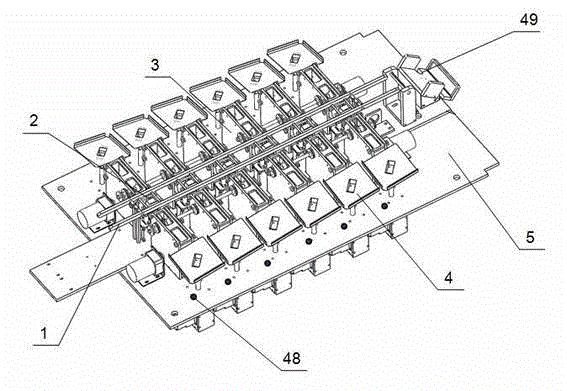

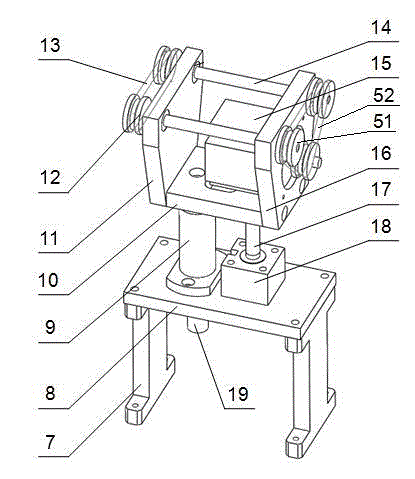

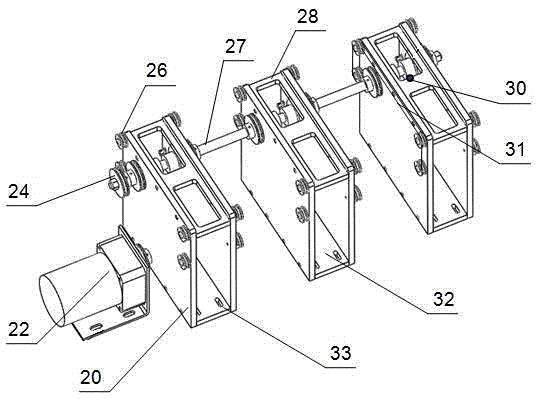

[0023] Such as figure 1 As shown, a silicon wafer or cell detection, sorting and blanking system includes a rectangular installation base plate 5, and the top surface of the installation base plate 5 is installed with a main transmission mechanism for transmitting silicon wafers / cells along the length direction of the installation base plate 5. The main transmission mechanism The end of the transmission is provided with a main conveyor belt film box 49, and the two sides of the main transmission mechanism are evenly equipped with 6 groups of film box lifting mechanisms 4, and between the main transmission mechanism and the film box lifting mechanism 4, there is a Silicon wafers / batteries are transported to the longitudinal transmission mechanism 3 on the cassette lifting mechanism; the main transmission mechanism includes two parallel main conveyor belts 1, and 6 groups are evenly arranged between the two main conveyor belts 1 for lifting silicon wafers / cells and transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com