A graphite boat for a crystalline silicon solar energy PERC battery and a saturation process thereof

A graphite boat and solar energy technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as the quality of the back passivation film affecting the service life of the graphite boat, the uneven surface of the graphite boat, and the corrosion of the silicon nitride film. Graphite boat, shortened saturation process time, and the effect of shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

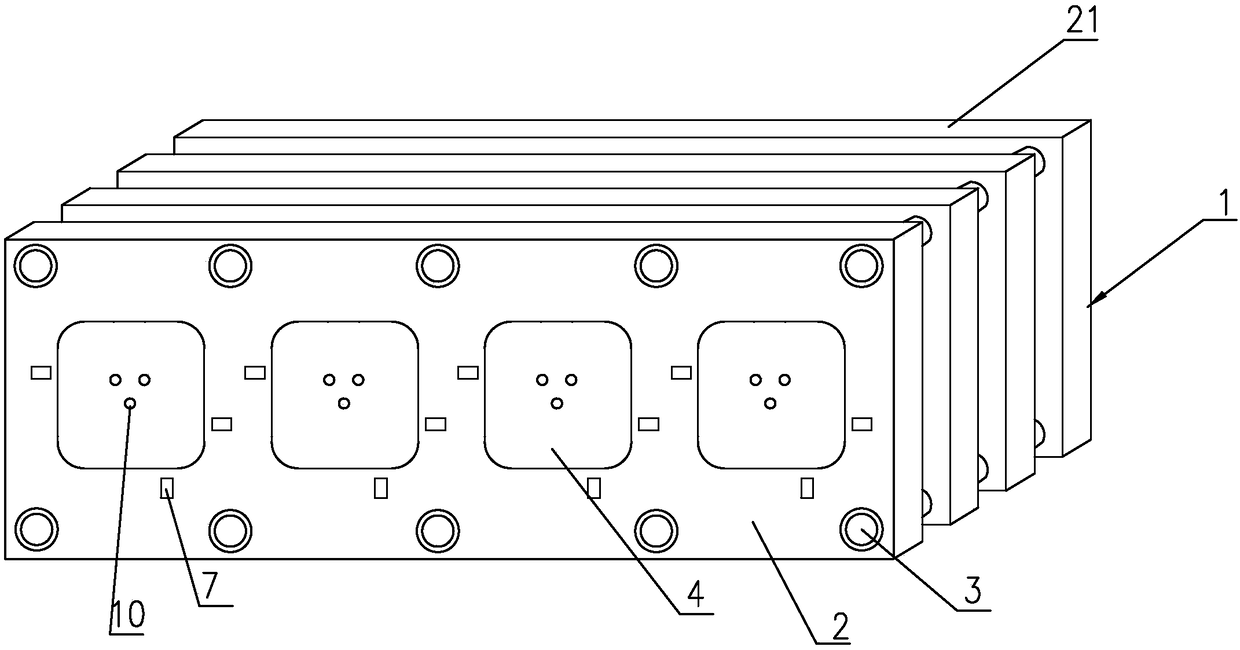

[0024] Such as figure 1 As shown, a graphite boat 1 for crystalline silicon solar PERC cells of the present invention includes a graphite boat body, which is a prior art, and it mainly consists of insulating rods 3 and several unit boat sheets 21 arranged in the horizontal direction. Composition, the insulating rod 3 runs through the periphery of each unit boat 21 horizontally to connect and fix all the unit boats together. The inner and outer surfaces of the unit boats on the two outsides are provided with some grooves 4 that are identical in shape to the silicon wafer and whose size is smaller than the size of the silicon wafer. Vacuumized pores 10, the unit boat in the middle is provided with a number of through holes with the same shape as the silicon wafer and smaller than the size of the silicon wafer, and there are clamping points for fixing the silicon wafer on the periphery of the groove 4 and the through hole 7.

[0025] A SiC film 2 is coated on the entire surface...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 lies in that the thickness of the SiC film plated on the graphite boat body is 800nm for the graphite boat used for the crystal silicon solar PERC cell.

[0035] The saturation process of the graphite boat for the above crystalline silicon solar PERC cell specifically includes the following steps:

[0036] (1) Put the cleaned and fully dried graphite boat body into the tubular PECVD furnace tube and vacuumize it;

[0037] (2) Set the deposition temperature of the furnace tube to 500°C;

[0038] (3) After reaching the deposition temperature, use NH3, the flow rate is 6slm, and the furnace tube pressure is 2000mtorr, and the RF power supply is 8000W, and the graphite boat body is discharged for 10min;

[0039] (4) After the discharge pretreatment is completed, 10slm CH4 and 1500sccm SiH4 are passed into the furnace tube, the furnace tube pressure is 2000mtorr, the RF power supply is 8000W, the RF duty ratio is 5:5...

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 lies in that the thickness of the SiC film plated on the graphite boat body is 1200nm for the graphite boat used in the crystal silicon solar PERC cell.

[0043] The saturation process of the graphite boat for the above crystalline silicon solar PERC cell specifically includes the following steps:

[0044] (1) Put the cleaned and fully dried graphite boat body into the tubular PECVD furnace tube and vacuumize it;

[0045] (2) Set the deposition temperature of the furnace tube to 450°C;

[0046] (3) After reaching the deposition temperature, use NH3, the flow rate is 6slm, and the furnace tube pressure is 1500mtorr, and the RF power supply is 6000W, and the graphite boat body is discharged for 6min;

[0047] (4) After the discharge pretreatment is completed, 8slm CH4 and 600sccm SiH4 are passed into the furnace tube, the furnace tube pressure is 1500mtorr, the radio frequency power supply is 6000W, the radio freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com