Double side continuous series welding system for fragment crystal silicon chip and welding method thereof

A technology for crystalline silicon wafers and welding systems, which is applied in semiconductor devices, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of low welding efficiency, lack of welding equipment, and increased fragmentation rate, etc., and achieve high welding success rate , Improve welding efficiency and reduce the effect of fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

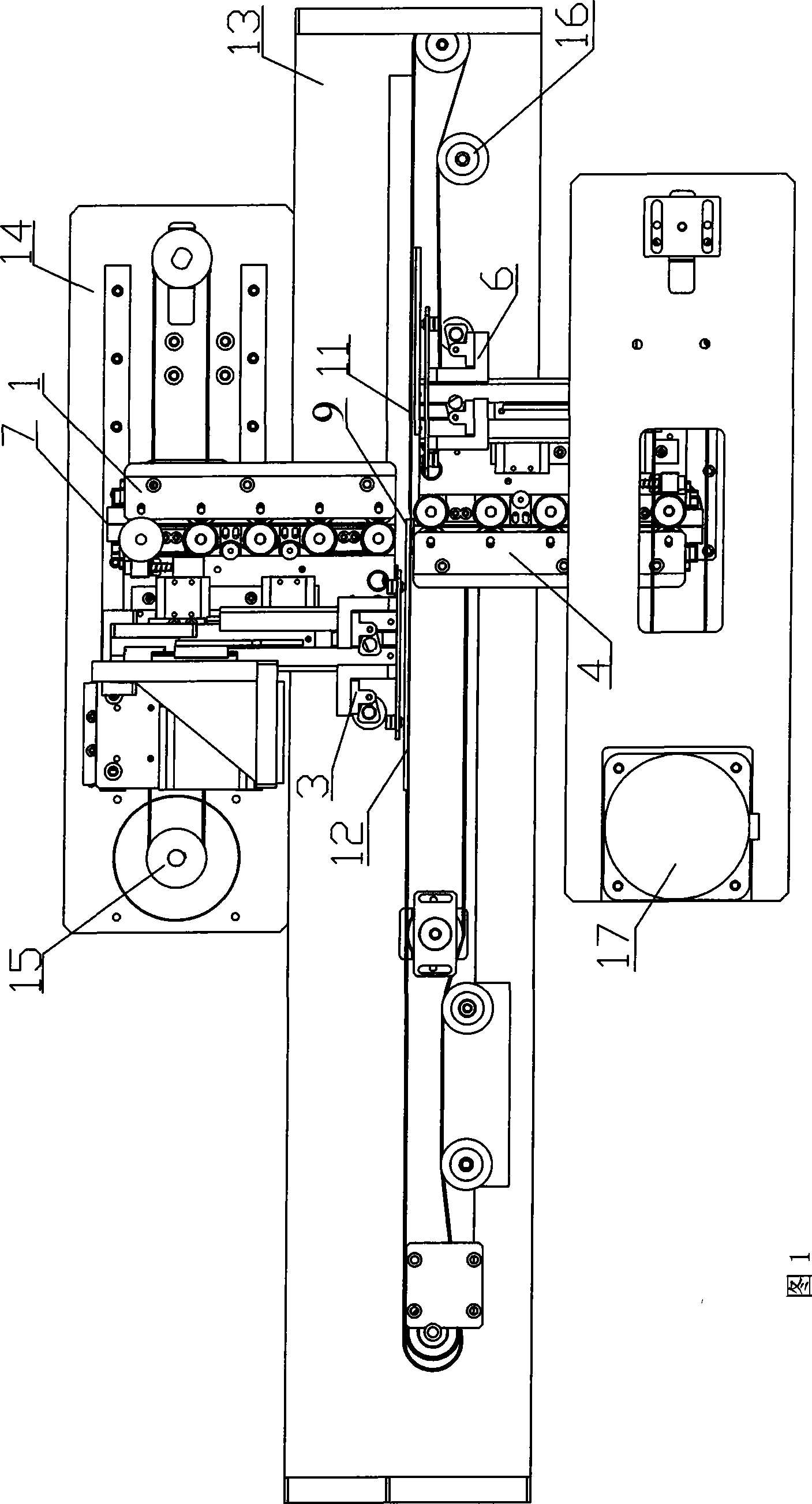

[0060] The double-sided continuous series welding system for fragile crystalline silicon wafers and its welding method of the present invention will be described in detail below with reference to the embodiments and drawings.

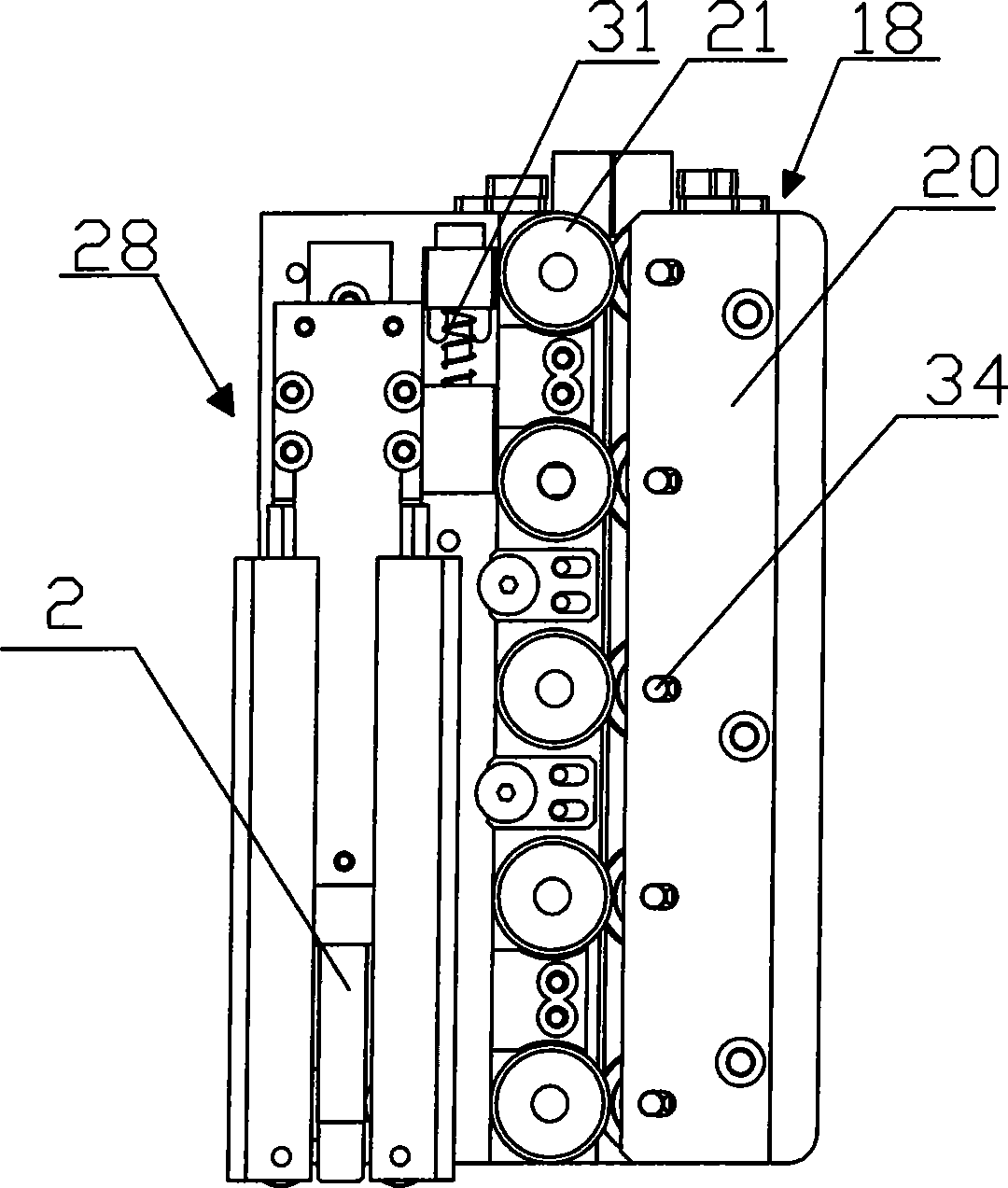

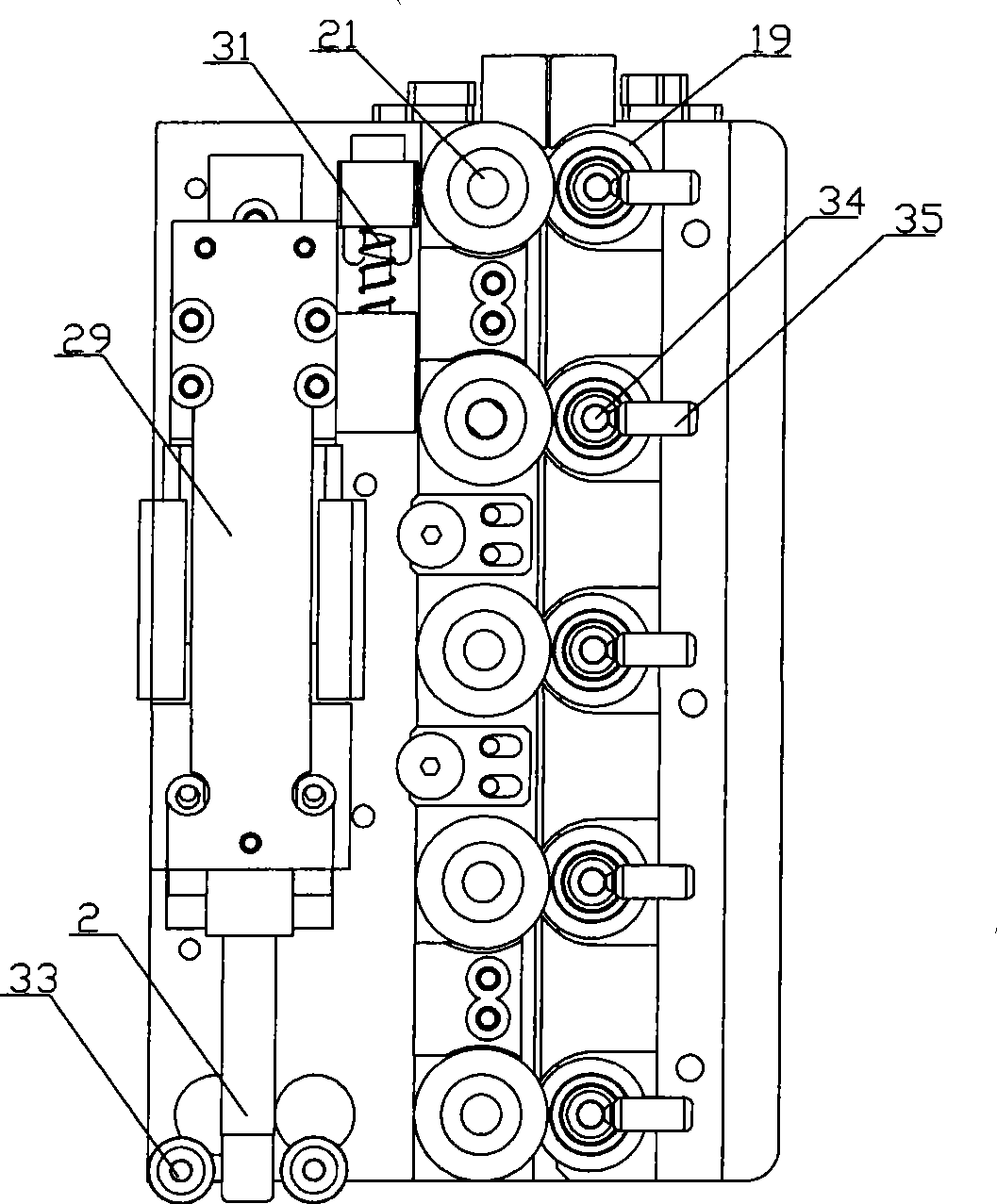

[0061] As shown in Figure 1, the double-sided continuous series welding system for fragile crystalline silicon wafers of the present invention includes a support 13, the upper side of the support 13 is provided with an upper fixing plate 14, and the upper fixing plate 14 is provided with an upper welding assembly 1 that can move in parallel and is used for fixing and conveying the welding strip and welding, and a driving motor 15 that drives the upper welding assembly 1 to move in parallel; the support 13 is located on the upper welding assembly The lower side of 1 is provided with a transmission mechanism 16 that supports and moves the crystalline silicon wafer 11 to be welded, and an upper positioning assembly 3 for positioning the crystalline silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com