Efficient dust removal smoke hood for coke pusher of coke oven

A technology for pushing coke cars and coke ovens, which is used in coke ovens, smoke removal, furnace safety devices, etc., to achieve the effects of reducing action links, good equipment integrity, and excellent environmental effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

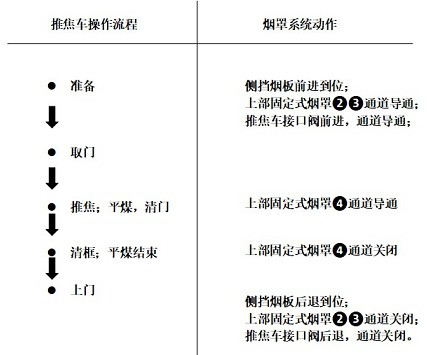

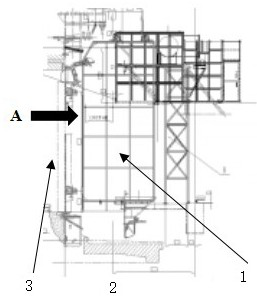

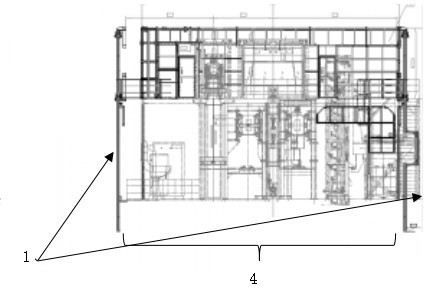

[0021] The invention provides a high-efficiency fume hood for a coke oven push car, which cooperates with the dust removal on the coke push vehicle. Aiming at the characteristics of smoke and dust generated on the machine side of the large-scale coke oven during the coke push process, the structure and action mode of the fume hood are redesigned to achieve The smoke and dust in the coke pushing process of the coke oven are all effectively collected to achieve the purpose of a smokeless coke oven.

[0022] 1. Add side smoke baffles and drive hydraulic cylinders on both sides of the coke pusher. The hydraulic cylinders are connected to the side baffles through buffer bases with springs. The height of the side smoke baffles (10m) starts at 1.5m from the machine side operating platform. , all the way to the top of the smoke hood on the upper part of the coke pushing car, driven by a hydraulic cylinder, opened before the coke pushing operation, and retracted before the coke pushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com