Vertical spinning dive pulverizer

A pulverizer and swirling technology, applied in the field of vertical swirling pulverizers, can solve the problems of short service life, low production capacity, inability to classify, etc., to improve service life, safety and reliability, improve production capacity, and protect the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

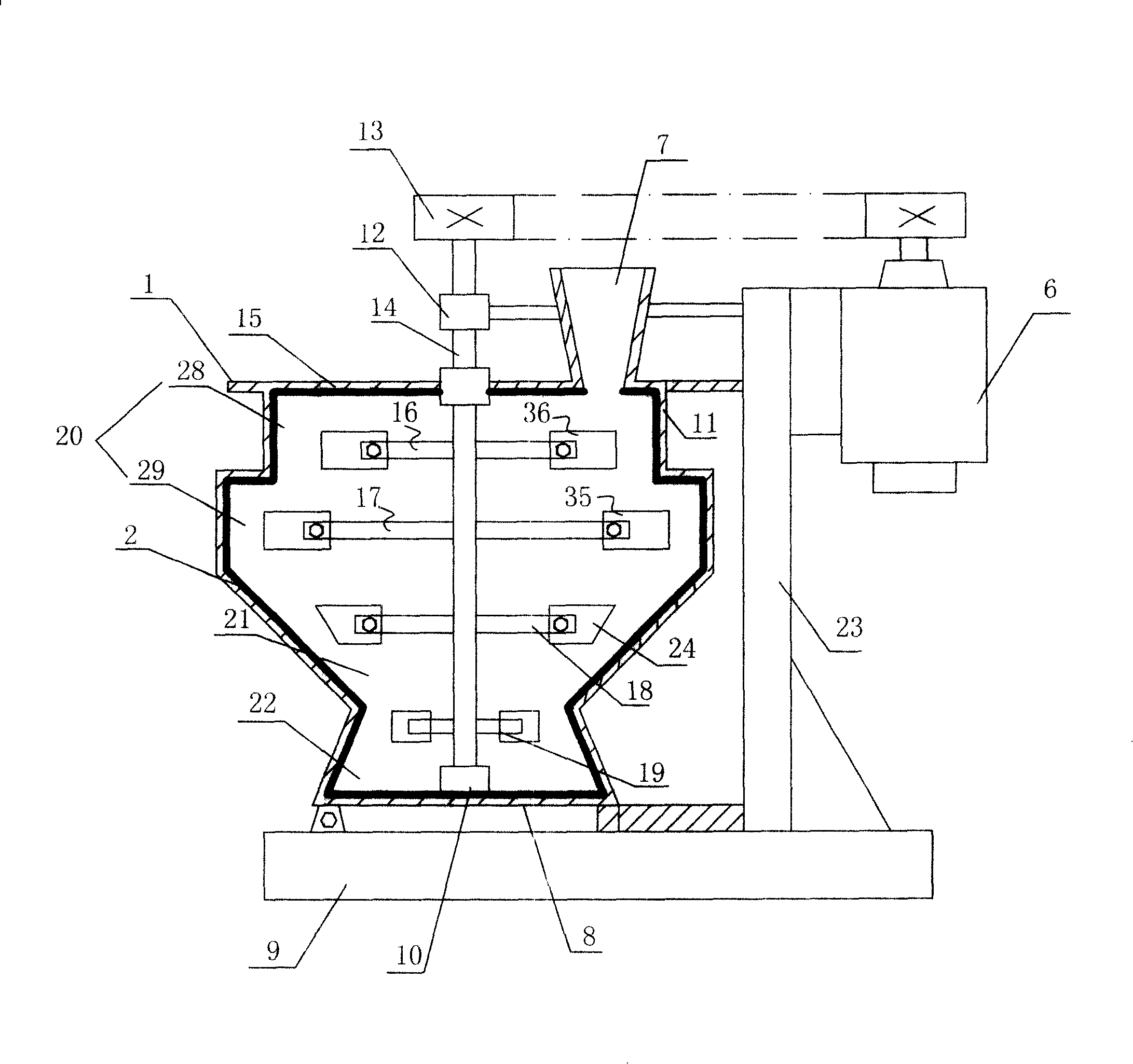

[0018] Embodiment: with reference to accompanying drawing, a kind of vertical punching and rotating pulverizer comprises the casing (1) that is located on the base (9), the support frame (23) and the motor (6) on it, is located at casing ( 1) The built-in liner (2) on the inner wall, the built-in liner (2) is made of hard wear-resistant material to prolong the service life of the machine. For convenience of maintenance, casing (1) is divided into movable casing (15) and fixed casing (11), and the bottom of movable casing (15) is connected on the base (9) by hinge, and the top is connected with fixed casing (11). ) is connected by bolts, and the fixed casing (11) is directly fixed on the base (9). The rotating main shaft (14) runs through the center of the casing (1) and is vertically arranged in a vertical structure. One end is connected to the thrust bearing on the base (9), and the other end is connected to the motor (6) through the bearing seat (12). ) driven drive pulley ...

Embodiment 2

[0023] Embodiment 2: with reference to accompanying drawing 1, accompanying drawing 2, the taper of the grading cavity (21) of pulverizer (2) middle part is 40 °, and the outer edge of grading knife head (24) is an inclined plane, and its outer edge and conical The distance between the inner walls of the grading cavity (21) is 20 mm. The radius of rotation of the secondary crushing knife rest (17) is greater than the radius of rotation of the primary crushing knife rest (16), and the angle between the plane where the cutter head (35) is located and the main axis of rotation is 18 °. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com