Automatic accurate coating mechanism of solar cell

A solar cell, automatic technology, applied in coatings, circuits, photovoltaic power generation, etc., can solve problems such as the inability to accurately control the thickness of the adhesive layer, and achieve the effects of avoiding damage to human health, improving efficiency, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

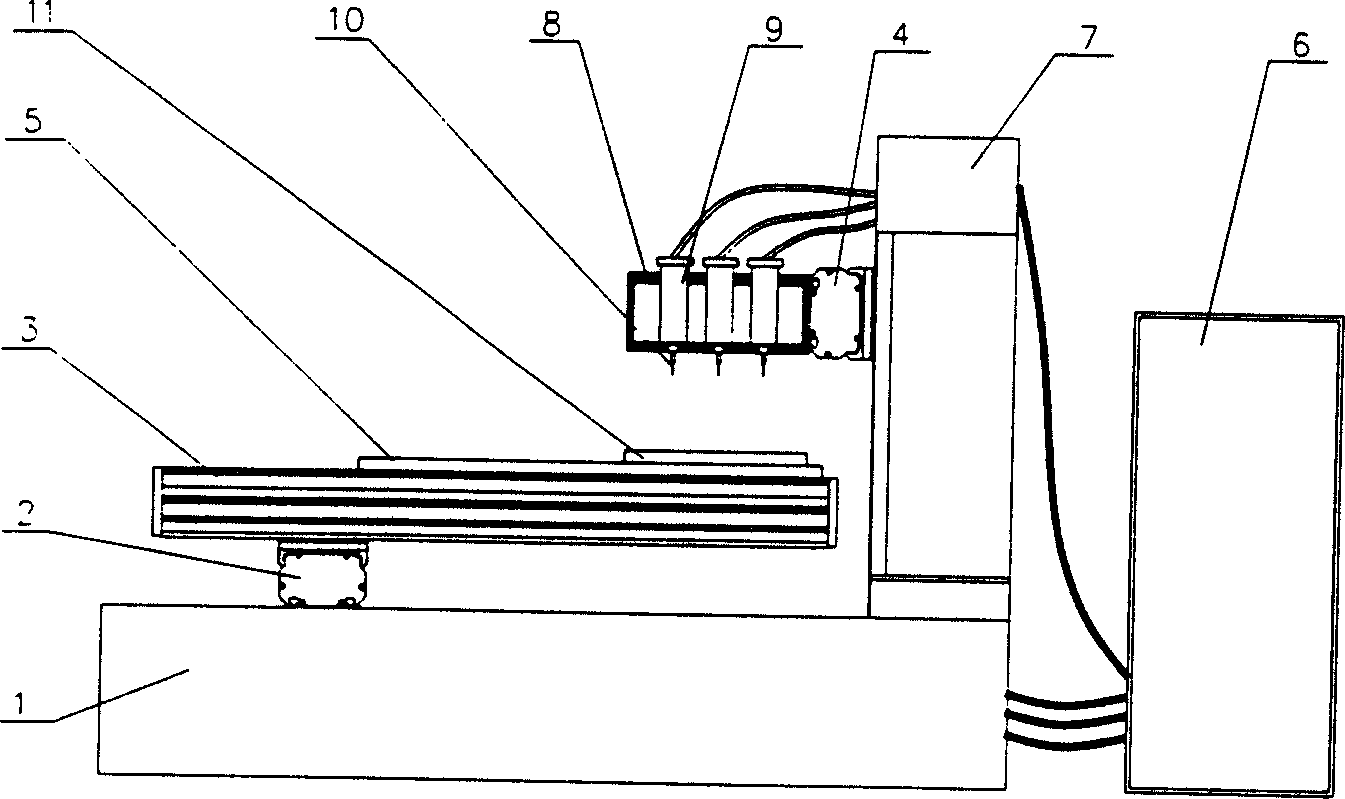

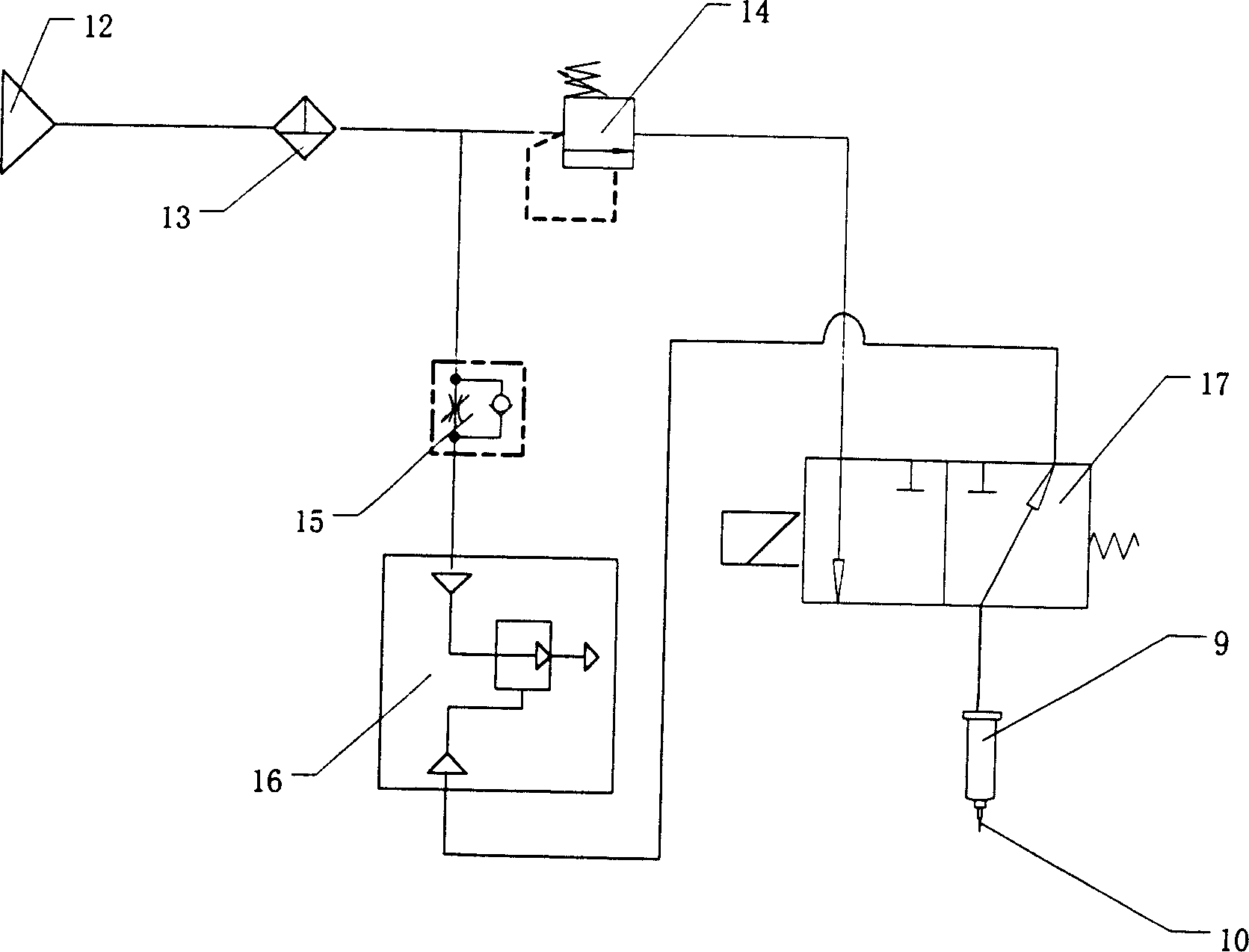

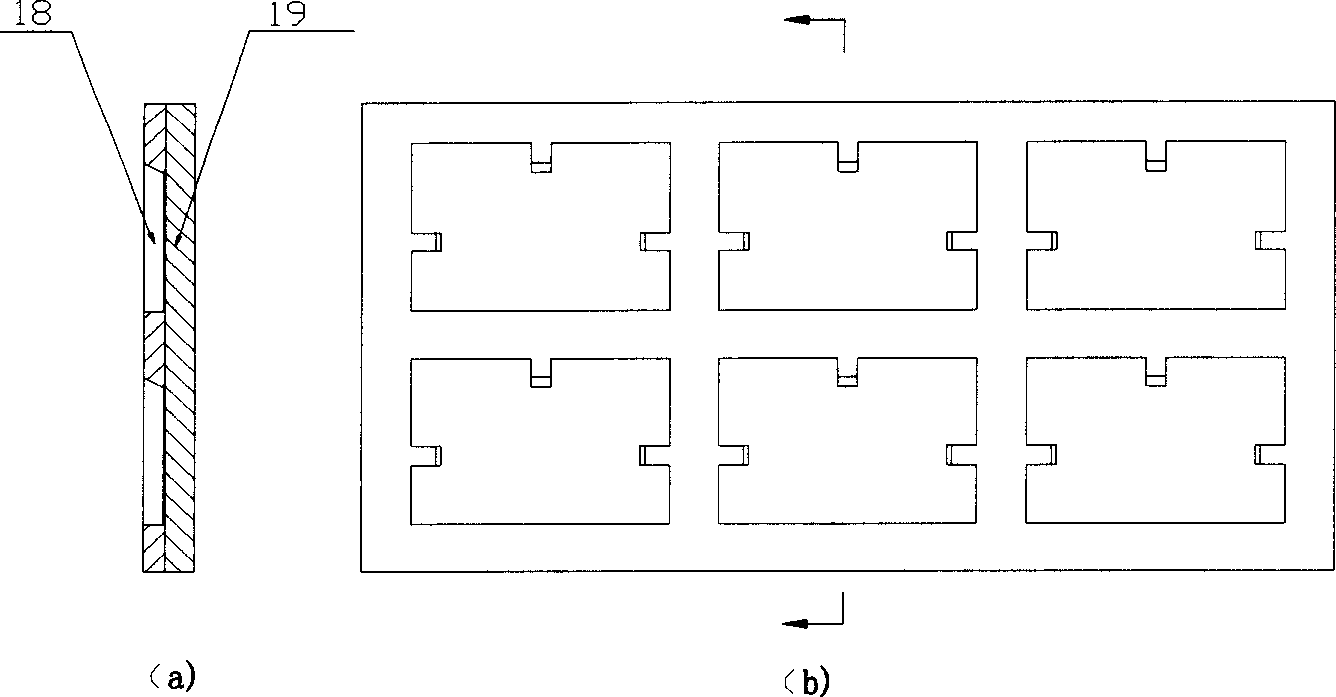

[0022] The gluing mechanism of the present invention mainly comprises: X, Y, Z three-degree-of-freedom automatic moving device, electric control device 6, gluing device and battery tray 11, and its connection mode is as follows figure 1 shown. Wherein, the X, Y, Z three-degree-of-freedom automatic moving device includes a machine base 1 , an X-axis moving unit 2 , a Y-axis moving unit 3 , a Z-axis moving unit 4 , and a workbench 5 . The track of the X-axis moving unit 2 is installed on the machine base 1, the track of the Y-axis moving unit 3 is installed on the sliding table of the X-axis moving unit 2, and the workbench 5 is fixed on the sliding table of the Y-axis moving unit 3, and the Z-axis The rails of the mobile unit 4 are installed on the machine base 1 . X, Y and Z-axis moving units 2, 3 and 4 all adopt the structure guided by roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com