An automatic quantitative acid supplementation device for battery processing

A technology for battery treatment and acid replenishment, which is applied to battery pack parts, circuits, electrical components, etc. It can solve problems such as increased raw material costs, potential safety hazards caused by acid spillage, and hidden dangers of battery capacity consistency in batch maintenance. It is convenient for management and quality control, solves potential safety hazards and quality problems, and effectively controls the effect of product quality status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

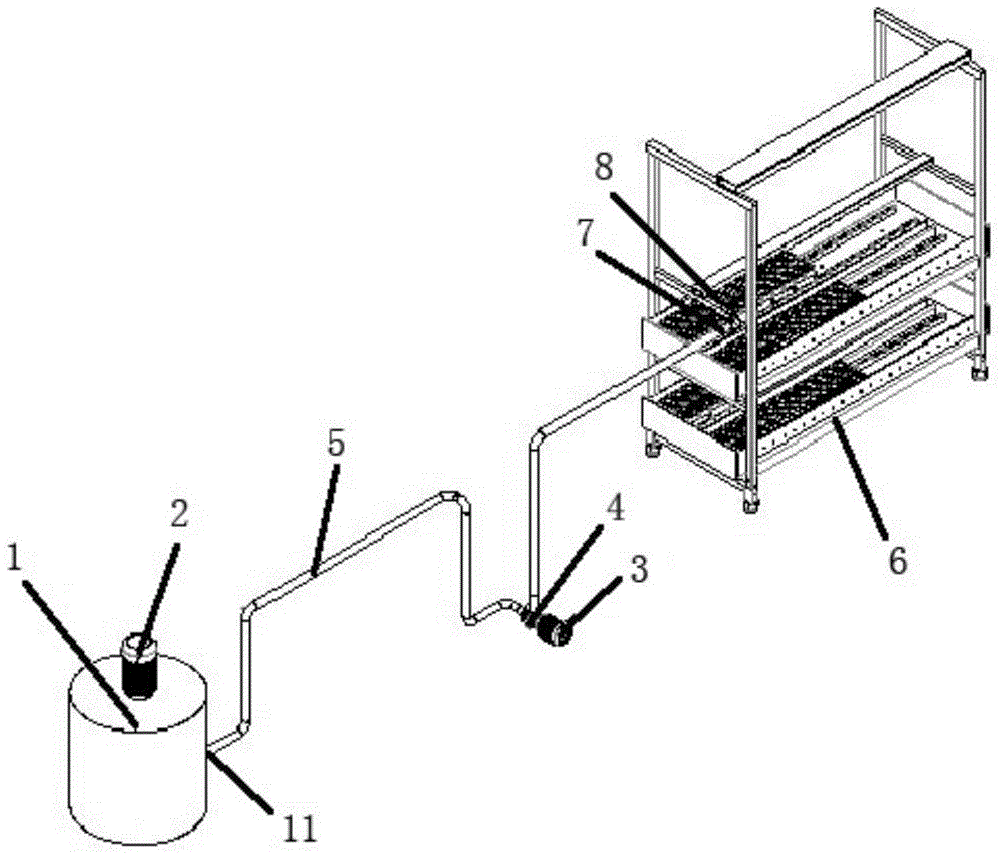

[0017] Such as figure 1 , 2 As shown, it is an embodiment 1 of an automatic quantitative acid replenishing device for battery treatment of the present invention, which includes an acid storage 1 for storing acid and a charging rack 6 for placing batteries to be charged. The acid storage 1 The side wall is provided with an acid outlet 11, and the charging stand 6 is provided with an acid replenishing device 8 for replenishing acid, and the acid outlet 11 is connected to the acid replenishing device 8 through an acid delivery pipeline 5, and the acid delivery A magnetic pump 3 is provided in the middle of the acid pipeline 5, and a pressure converter 4 is installed on the magnetic pump 3, and a control valve 7 is provided on the end of the acid delivery pipeline 5 close to the acid supply device 8. One or more acid outlets 11 are opened on the side wall of the acid storage 1 . A stirring device 2 for stirring the acid liquid is installed on the acid liquid storage 1 .

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com