Glue layer thickness controlable continuous glue-dropping process for packing solar cell

A solar cell and encapsulation adhesive technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, circuits, etc., can solve the problems of poor effect, inability to accurately control the position and thickness of the adhesive layer, etc., to achieve the adhesive layer Thickness controllable to meet, avoid damage to human health, avoid the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

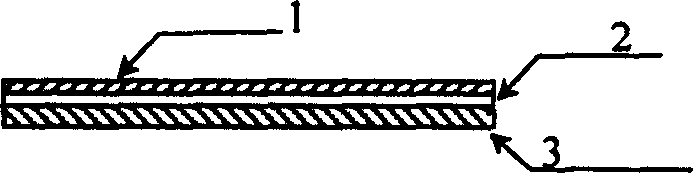

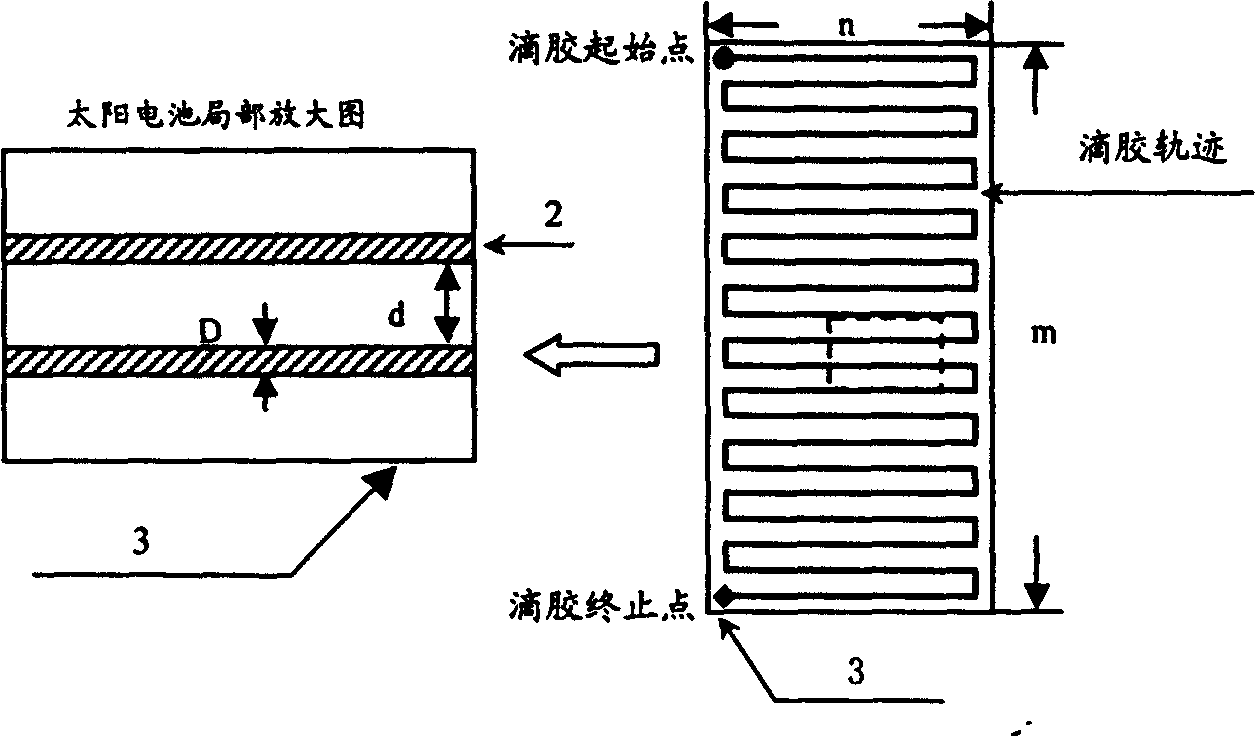

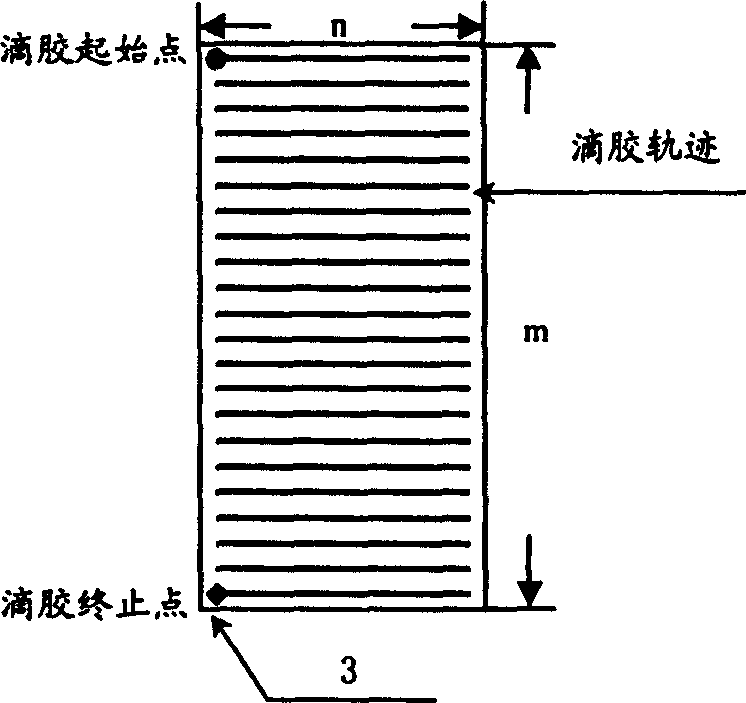

[0027] Such as figure 1 As shown, there is a uniform adhesive layer 2 between the solar cell 3 and the surface protection layer 1 . The thickness of protective layer 1 is: 0.12 -0.02 +0.04 mm, the overall dimension is: 40.20±0.10×20.10±0.10mm The thickness of the solar cell is: 0.20 -0.01 +0.04 mm. The thickness of the adhesive layer 2 is required to be less than 0.1 mm. In order to meet the thickness requirement of the adhesive layer 2, the present invention utilizes the viscosity and fluidity of the colloid to spread the adhesive layer 2 evenly on the surface of the solar cell 3 before the protective layer 1 is packaged. The specific method is as follows:

[0028] At room temperature (15-25°C), measure the external dimensions of the solar cell 3 as m=40.25±0.05, n=20.20±0.05. According to the required thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com