Flip chip packaging structure and packaging method

A technology of flip-chip packaging and sealant, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., and can solve the problems of inability to effectively control the size and randomness of the overflow of the adhesive material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

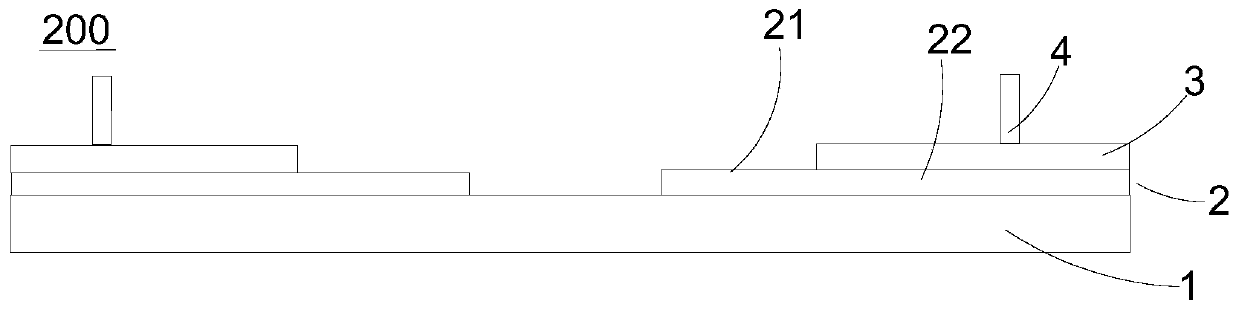

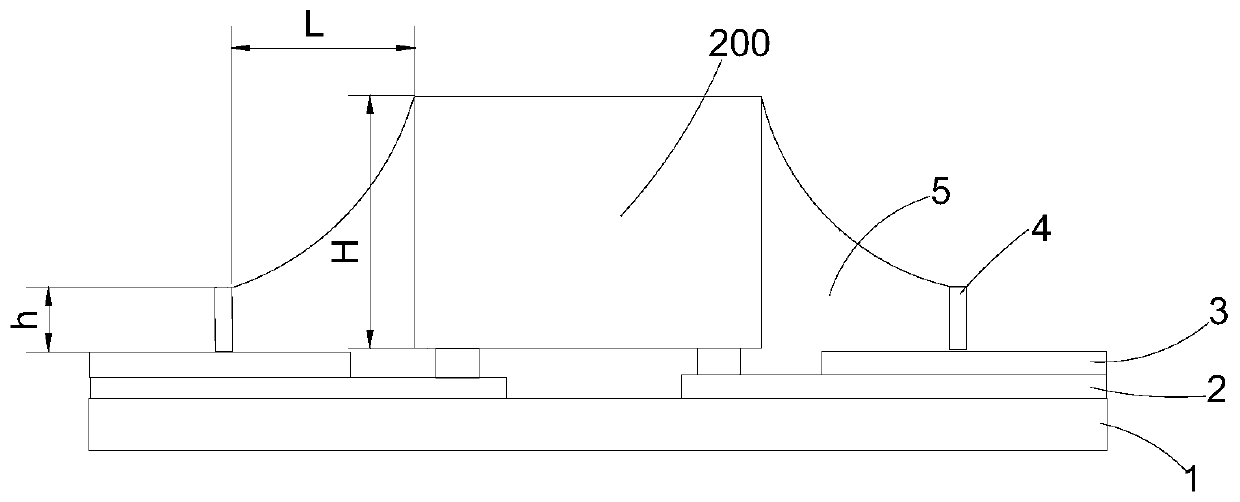

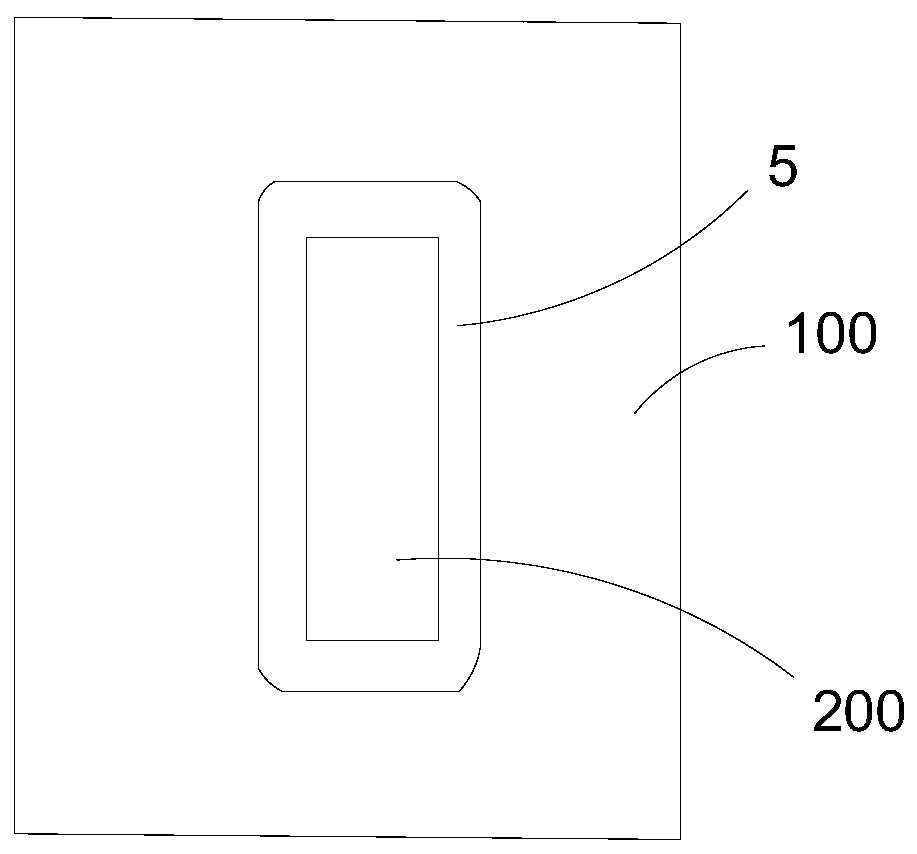

[0028] Embodiments of the present invention: as Figure 1-3 As shown, a flexible circuit board is disclosed, including a base layer 1, a circuit layer 2 and a protective layer 3 arranged on the surface of the base layer 1, and the circuit layer 2 has an internal connection area 21 for connecting with a flip chip 200 and the coverage area 22 covered by said protective layer 3 . The flexible circuit board also has a barrier 4 disposed on the protective layer 3 and protruding in a direction away from the protective layer 3 .

[0029] The covering area 22 is covered by the protection layer 3 to protect the wiring thereon, and the inner connection area 21 is exposed without being covered by the protection layer 3 for connection and fixation with the pins of the flip chip 200 . The middle positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com