Dry and wet pre-mixed mortar production device

A technology for ready-mixed mortar and production equipment, which is applied in clay preparation equipment, mixing plant, mixing operation control, etc. Without problems such as optimal allocation of resources, it achieves the effect of compact and reasonable structure layout, small footprint and strong production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

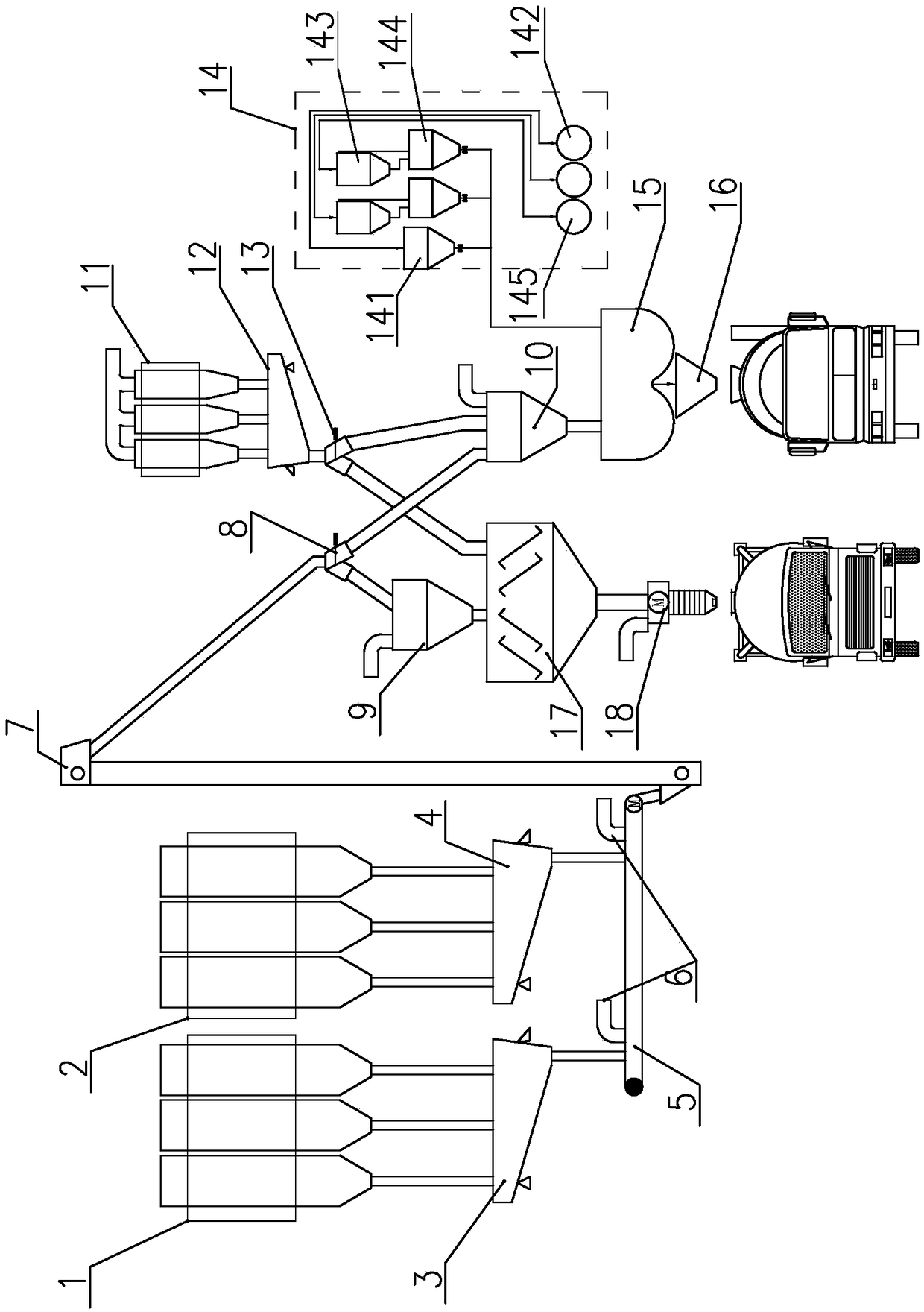

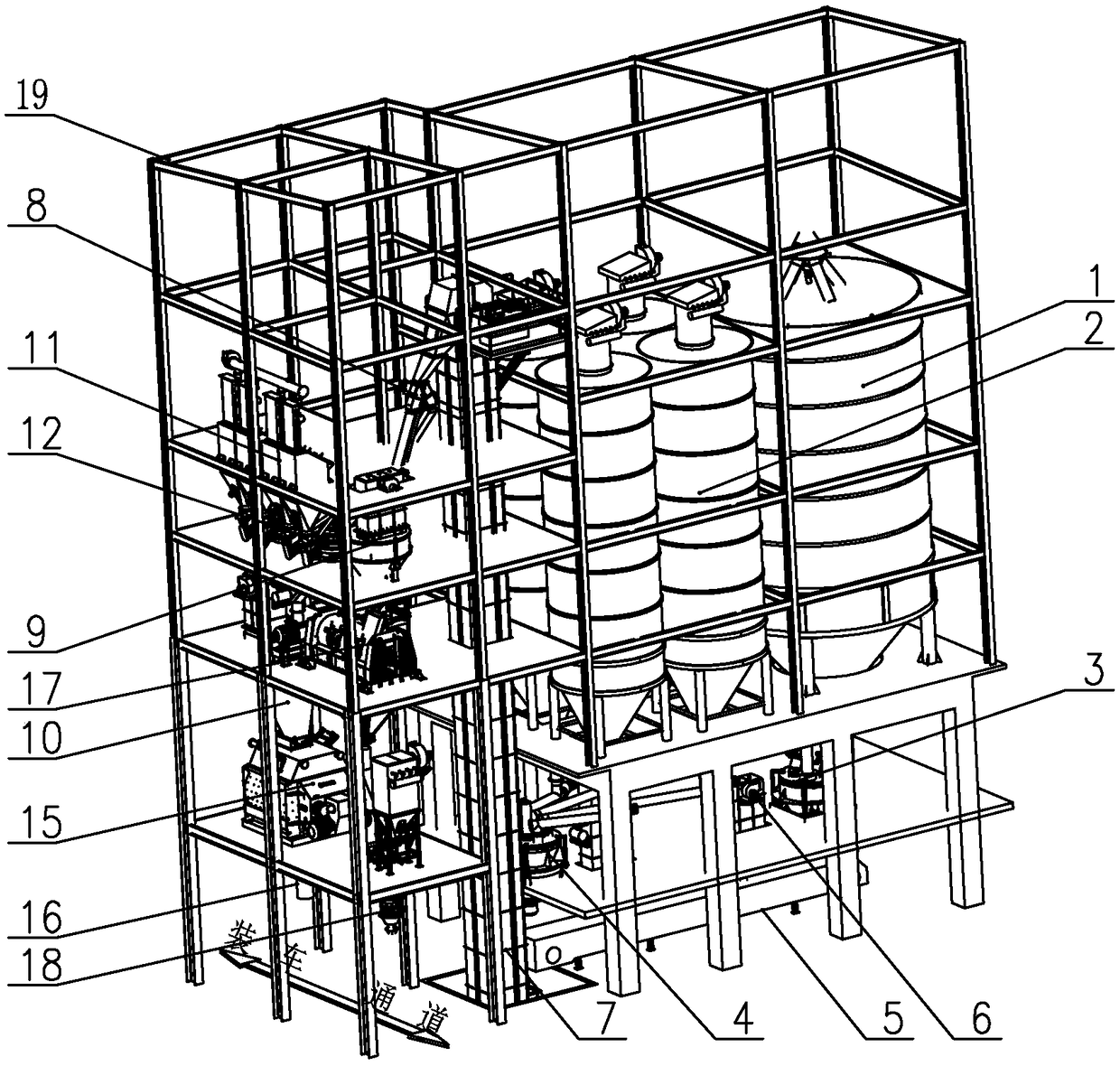

[0024] refer to figure 1 and figure 2 As shown, a dry and wet ready-mixed mortar production device includes a steel structure main building 19, a main raw material storage and batching system, a metering material delivery and lifting system, a main raw material distribution device 8, a dry mixing temporary storage bucket 9, a wet mixing Temporary storage bucket 10, solid admixture storage and batching system, solid admixture distributing device 13, wet mixing mortar liquid distribution system 14, wet mixing host 15, dry mixing host 17, steel structure main building 19 for carrying ready-mixed mortar production device , the steel structure main building 19 is provided with a loading channel shared by dry mixing and wet mixing.

[0025] The main raw material storage and batching system includes sand storage bin 1, powder storage bin 2, sand scale 3 and powder scale 4, sand scale 3 is connected to the bottom of sand storage bin 1, powder scale 4 is connected to the bottom of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com