Technology for preparing calcium chloride by using waste slurry

A technology of waste slurry and calcium chloride, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problems of unstable operation of the treatment system, high treatment cost, and low safety factor, and achieve Reduce processing costs, avoid environmental pollution, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

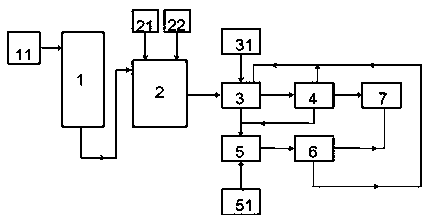

[0026] A kind of technology that utilizes waste slurry to prepare calcium chloride comprises hydrolysis process, washing separation process, precision filtration process and product process, and described hydrolysis process comprises dissolving tank 1, reactor 2, and the upper part of described dissolving tank 1 and waste slurry Storage tank 11 links to each other, and the bottom of described dissolving tank 1 links to each other with reactor 2, and the top of described reactor 2 is connected with first water storage tank 21, lime device 22; Described washing separation process comprises centrifugal separation device 3, and The top of the centrifugal separation device 3 is connected to the second water storage tank 31, the upper part of the centrifugal separation device 3 is provided with an overflow port, and the bottom of the centrifugal separation device 3 is provided with a waste residue discharge port; the precision filtration process includes The first filter device 4, th...

Embodiment 2

[0035]A kind of technology that utilizes waste slurry to prepare calcium chloride comprises hydrolysis process, washing separation process, precision filtration process and product process, and described hydrolysis process comprises dissolving tank 1, reactor 2, and the upper part of described dissolving tank 1 and waste slurry Storage tank 11 links to each other, and the bottom of described dissolving tank 1 links to each other with reactor 2, and the top of described reactor 2 is connected with first water storage tank 21, lime device 22; Described washing separation process comprises centrifugal separation device 3, and The top of the centrifugal separation device 3 is connected to the second water storage tank 31, the upper part of the centrifugal separation device 3 is provided with an overflow port, and the bottom of the centrifugal separation device 3 is provided with a waste residue discharge port; the precision filtration process includes The first filter device 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com