Coal mine underground mining, dress and filling integral method

A technology for coal mines and raw coal, which is applied in the field of integration of underground mining, selection and charging in coal mines, can solve problems such as land occupation, energy consumption, environmental pollution, etc., and achieve the effects of reducing ground emissions, relieving lifting pressure, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention is described further below in conjunction with accompanying drawing:

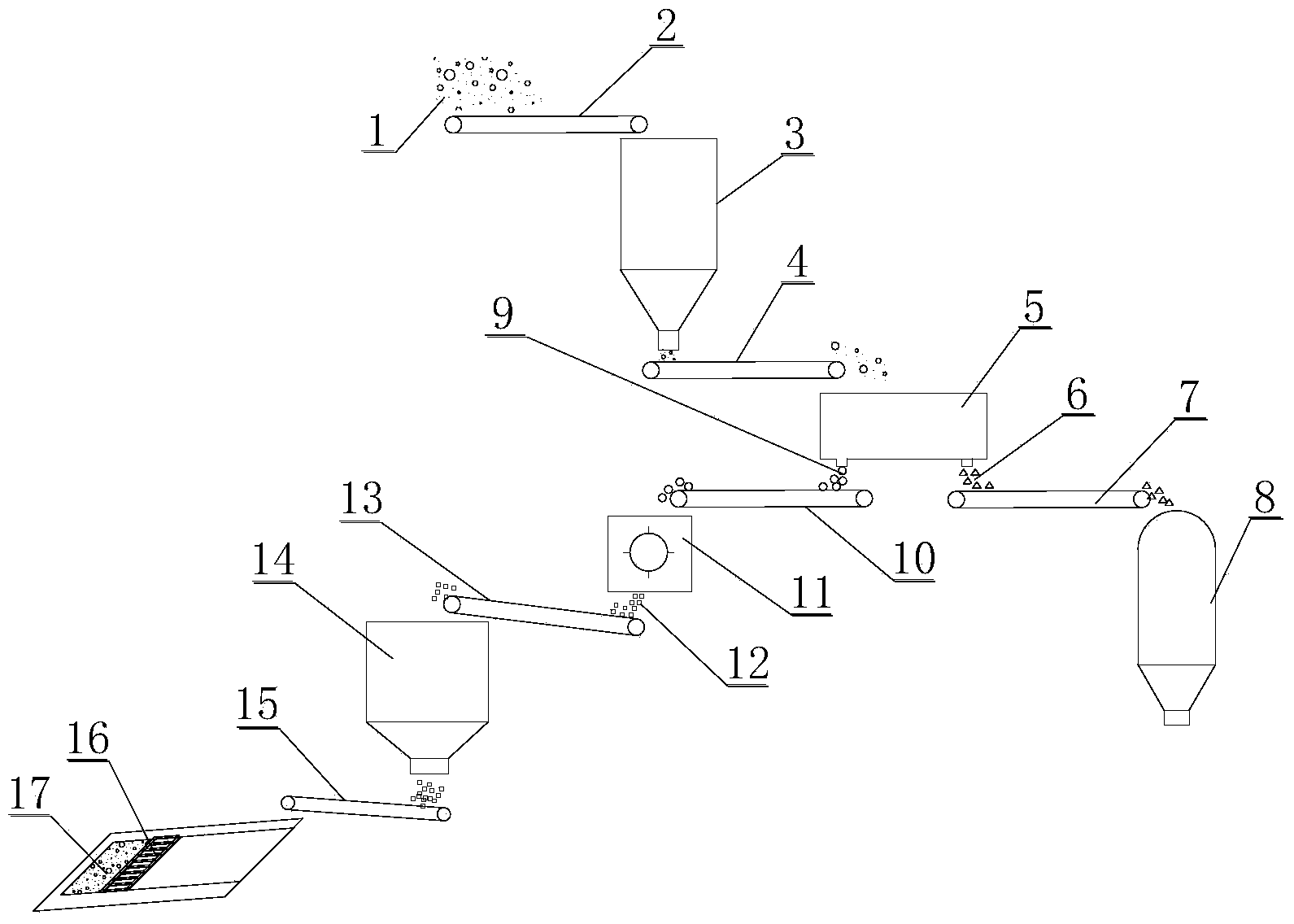

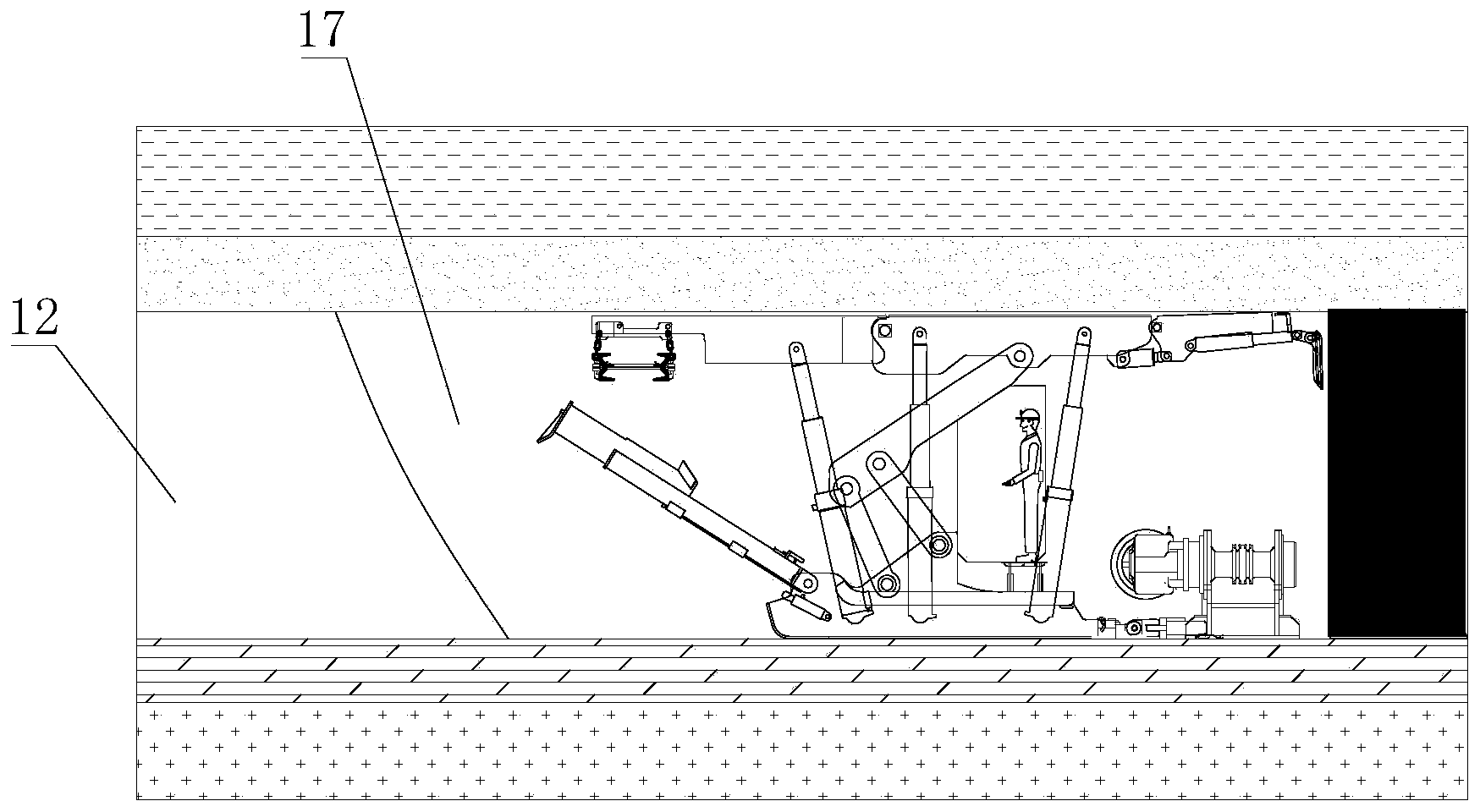

[0014] Such as figure 1 As shown, the integrated method of mining, dressing and filling in underground coal mines of the present invention adopts a raw coal belt conveyor 2, a raw coal bunker 3, a raw coal feeding belt conveyor 4, a washing system 5, a clean coal belt conveyor 7, Underground coal storage bin 8, gangue washing belt conveyor 10, crusher 11, gangue feeding belt conveyor 13, gangue bin 14, gangue filling belt conveyor 15, wherein: washing system 5 includes washing equipment and screening equipment; a raw coal bunker 3 is set under the coal belt conveyor 2, a raw coal feeding belt conveyor 4 is set under the raw coal bunker 3, and a washing system 5 is set at the output end of the raw coal feeding belt conveyor 4 , the clean coal belt conveyor 7 and the gangue belt conveyor 10 are respectively arranged under the washing system 5, the clean coal belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com