High-temperature water source heat pump unit

A water source heat pump unit, high temperature technology, applied in the direction of heating and cooling combination, refrigerator, compressor, etc., can solve the problems of unstable unit operation, large power consumption, low safety and reliability, etc., and achieve good environmental protection effect and economic effect , Save transportation costs and save investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

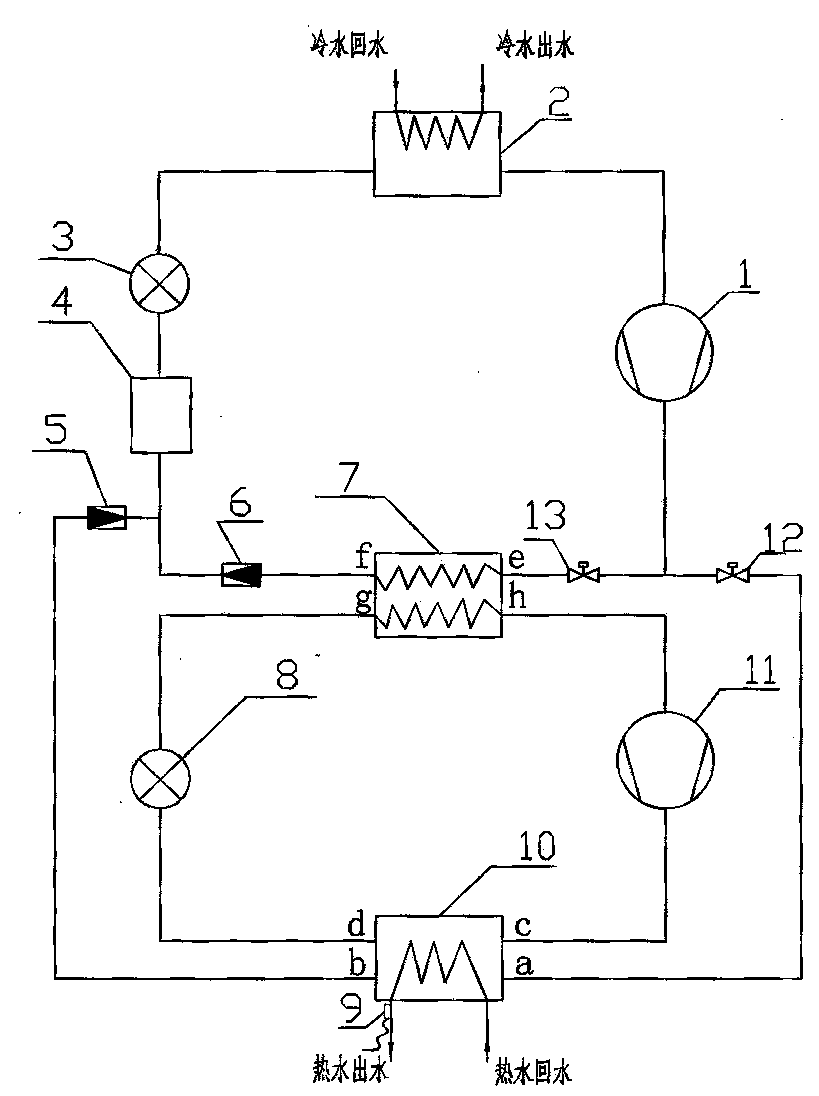

[0013] Embodiment: the designed high temperature water source heat pump unit, such as figure 1 Shown: the unit consists of a first compressor 1, a second compressor 11, a first heat exchanger 2, a second heat exchanger 10, a first throttling element 3, a second throttling element 8, and a liquid reservoir 4 , the first electromagnetic valve 12, the second electromagnetic valve 13, the second one-way valve 5, the first one-way valve 6, the intermediate heat exchanger 7, the temperature sensor 9 and the connecting pipeline. Their connection relationship is: the exhaust port of the first compressor 1 is connected with the refrigerant passage inlet e of the intermediate heat exchanger 7 through the second electromagnetic valve 13, and the refrigerant passage outlet f of the intermediate heat exchanger 7 passes through the first one-way valve 6 is connected to the refrigerant inlet of the liquid receiver 4, and the refrigerant outlet of the liquid receiver 4 is connected to the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com