Method for extracting gas from bedding level fractured well of ground coal seam roof

A coal seam roof and gas drainage technology, which is applied in the direction of gas discharge, mining fluid, directional drilling, etc., can solve the problems of limited drainage effect, difficult hole sealing, poor drainage effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

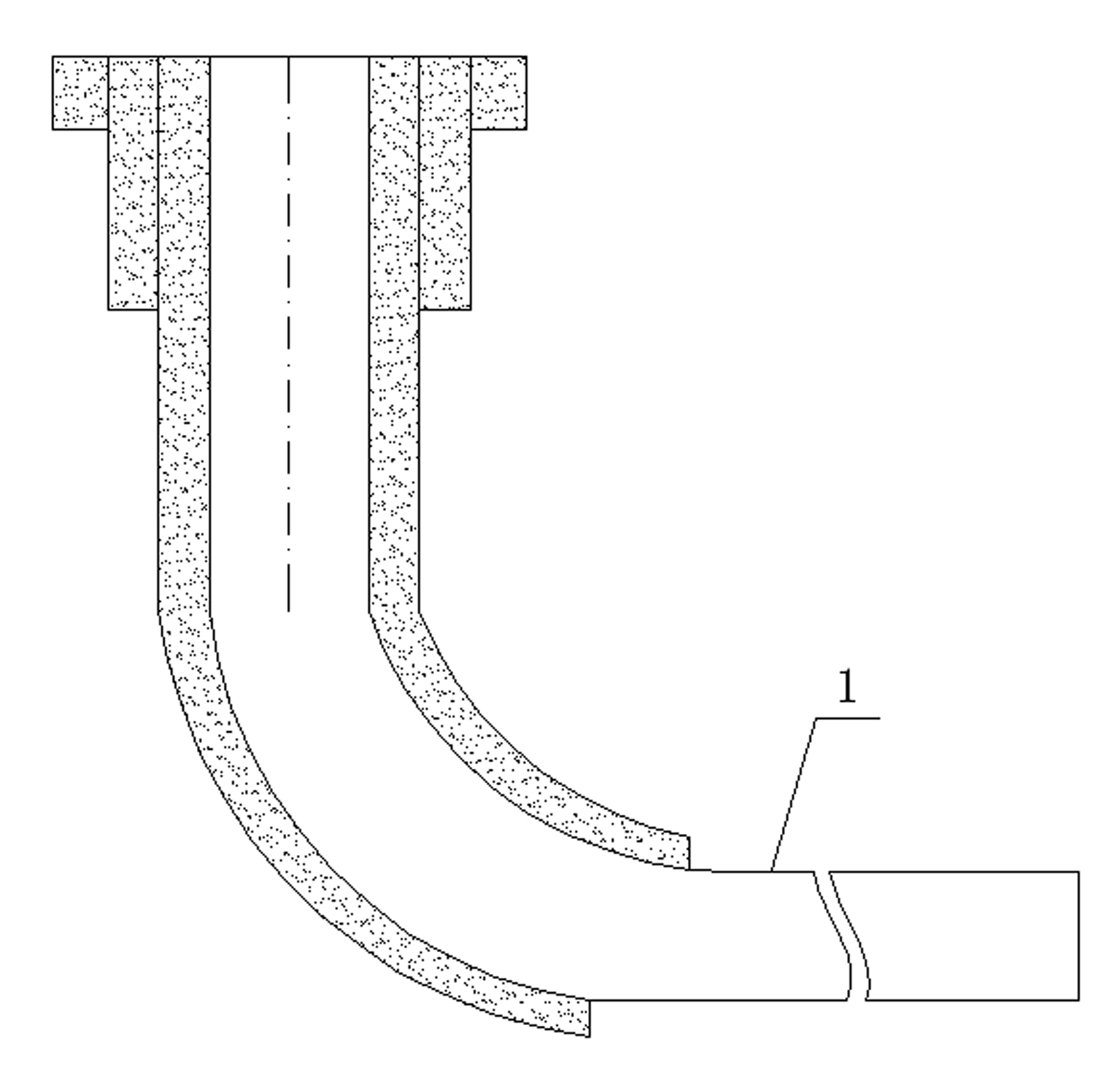

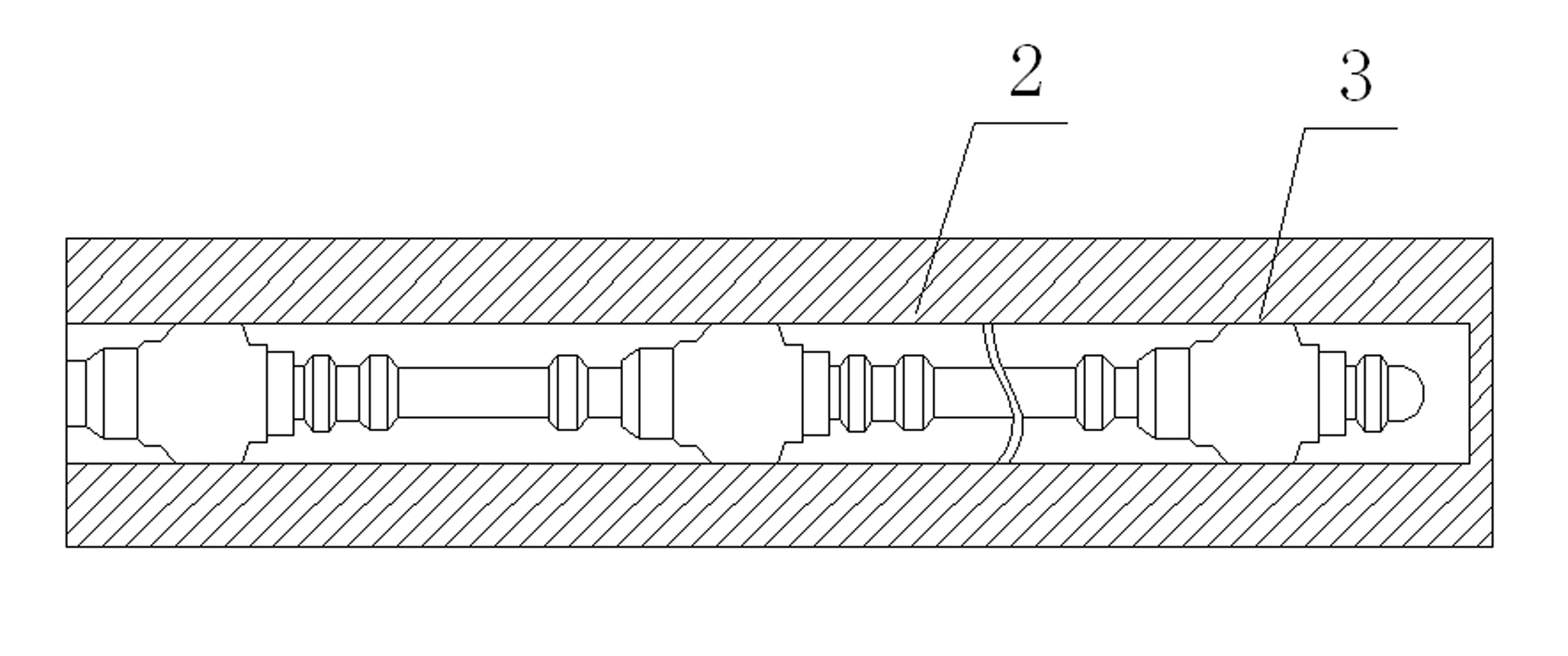

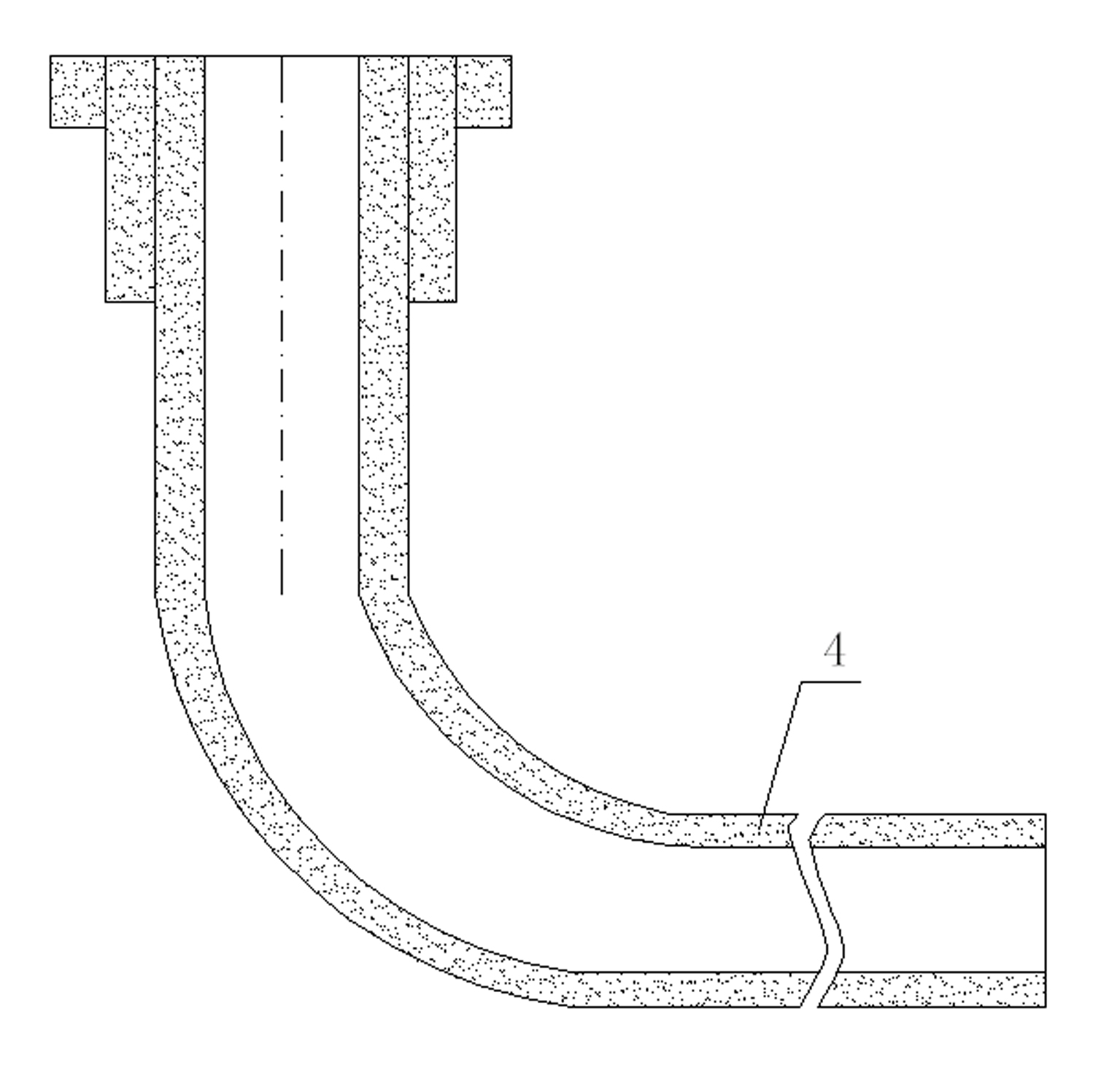

[0016] Example: such as figure 1 As shown in -4, the method for extracting gas from horizontal fracturing wells along the roof of the ground coal seam 2 is characterized in that it includes the following steps in sequence: (1) selecting the gas content greater than 8 m 3 / t coal reservoir; (2) Determine the position of the fractured zone produced by coal seam mining, and take the 3-7m rock strata in the middle and lower part of the fractured zone as the construction horizon of the horizontal section, or other favorable horizons determined by rock mechanics analysis; ( 3) Determine the location of the wellhead and build-up point according to the landing point of the horizontal section to achieve a large curvature radius increase. The build-up rate is selected to be 2~6° / 30m, and the drilling orientation is parallel to the coal mining face along the channel or perpendicular to the direction of the maximum principal stress , the length of the horizontal section is equal to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com